First layer solid infill lines lift in the middle?

[Scroll to bottom for solution. I'm still interested in theories of why this was happening.]

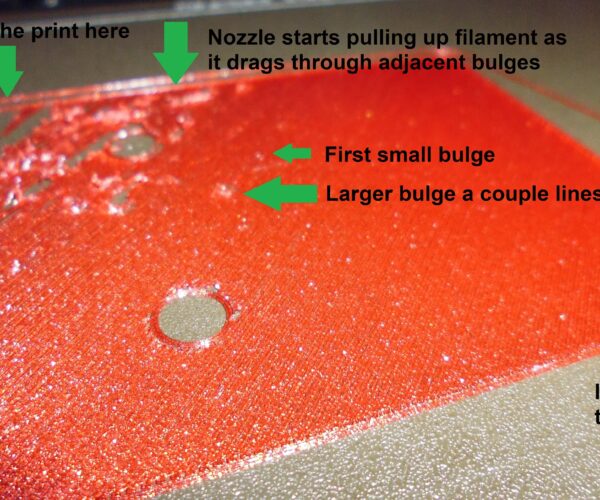

Since the 3.12.2 firmware update, I'm experiencing warping with PLA and adhesion failure with PETG. I'll focus on the PETG problem because that seems the most mysterious and it's completely reproducible. The skirt and perimeters go down perfectly, and the solid infill looks good as it begins. But then a few small bumps or bubbles appear in the middle of solid infill lines. As it continues to lay down the infill, the bumps become larger and more frequent until the nozzle catches one, causing it to drag plastic from an adjacent row.

Is this under- or over-extrusion?

This has become completely reproducible with most real prints. Oddly, the Prusa bed level test prints perfectly.

- Prusa Slicer 2.5.2

- Settings: 0.2mm QUALITY (modified only to increase minimum skirt loops to 2)

- Printer: Original Prusa i3 MK3S+, pre-assembled, firmware 3.12.2

- Filament: Prusament PETG Carmine Red Transparent (I didn't realize it had glitter when I ordered it). This spool was opened just a couple days ago, and used for one successful print just before I updated the firmware.

- Build Plate: Textured, like new

I've tried:

- Cleaning the build plate with IPA (before every attempt, while the plate is cool). I've even flipped to try the never-before-used side.

- Reslicing with the parts in a different position to see if the problem happens in a specific spot on the build plate or heated bed. It does not.

- A cold pull to make sure there's no obstruction in the nozzle. It came out perfectly clean and shaped.

- Cleaning the exterior of the nozzle (because a prior attempt accumulated a blob before I caught it happening). I heated the nozzle and pulled excess blobs off with needle nose pliers. I gently scrubbed with a brass brush. Then, after it cooled, I wiped the exterior with IPA on a shop towel.

- Cleaning dust out of the fans.

- Brushing the extruder gears with a soft toothbrush (which did dislodge a few small bits of filament).

- Lubricating all three axes (which I was due to do anyway).

- Checking the belt tensions.

- Running a self test.

- Running a Z calibration.

- Running a first layer calibration.

SOLVED: I was about to submit this when I tried switching back to an old spool of PETG (Prusament Orange). Boom. Everything is perfect again. Did I get a bad batch of the Prusament PETG Carmine Red Transparent?