Retraction procedure

Does anyone know the process used for retracting the filament before attempting to insert a new filament. I'm curious what it does because this seems to be the breaking issue of my upgrade. After retraction if it attempts to the filament it is unable to feed it back into the multiplexer. Does it stop the retraction with the end of the filament inside the metal tubes, before the tubes, after the tubes?

Thanks for any insight you can provide.

Re: Retraction procedure

Michael

The theory is that the filament is quickly unloaded and pulled back into the cooling tubes where it moves back and forth while cooling and forming a clean end for the next load.

Here's the GCode from my post processor:

M907 E750 ; Increase motor current

G4 S0 ; force increase to apply immediately

G1 E3.5 F2400 ' retract prime

G1 X153.7 Y52.3 E3.16304 F4000 ; "Ram" filament to cool - approx 10mm

G1 X153.7 Y52.9 E0.02993

G1 X90.3 Y52.9 E3.16304 F4600

G1 X90.3 Y53.5 E0.02993

G1 X153.7 Y53.5 E3.16304 F5200

G1 X153.7 Y54.1

G1 E-15 F5000 ; Unload 15mm (into PTFE)

G1 E-50 F5400 ; Unload 50mm quickly

G1 E-15 F3600 ; unload 15mm (into MUX)

G1 E-12 F3000 ; unload 12mm (into tube)

G1 X90.3 Y54.1 E10 F1600 ; Filament is now in tube - move back and forth while cooling

G1 X153.7 Y54.1 E-10

G1 X90.3 Y54.1 E5 F2400

G1 X153.7 Y54.1 E-5

G1 X90.3 Y54.1 E5 F3000

G1 X153.7 Y54.1 E-10

G1 X90.3 Y54.1 E10 F2400 ; final cooling movement is forward ready for next load

Hop this helps.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Retraction procedure

This is perfect. Unfortunately it led me to more questions...

Why is the initial extraction done in 4 commands as opposed to a single command where it ends up in the tube?

The problem I am seeing is that the final command of the retraction ends up just past the end of the metal tube and then a blob forms. I suspect that there is a shortage between the end of the tube and the nozzle. So I need to find out if the length of the PTFE in the hot end is maybe not correct.

UPDATE:

So I went and found an earlier post where you stated your ptfe tube is 41.2-41.5 mm long. I pulled mine out and it is not even close to that. Mine is 39mm long. So this 2.5mm shortage could certainly be a problem. I have a ton of ptfe in the right size so I will make a new tube and give it a spin. Thanks for the help. I've been doing 3D printers for 6 years now. Always an adventure.

Re: Retraction procedure

Michael

The PTFE tube official length is 41mm. You will not have any of this tubing as it is "high precision" 1.9mm internal diameter specially made by Festo for PR.

With regards to your query, the different speeds are used to get the filament tip past certain "obstacles"; if your filament tip is retraction to above the cooling tube, then there is something wrong, most likely too high temperature for the filament so not enough filament is being withdrawn.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Retraction procedure

I wouldn't count on me not having appropriate tubing. I have several reels of Medical/scientific grade ptfe tubing. 1.9mm is not an issue as 1.9x2.3 is a pretty standard size. And the tubing I have has a much higher lubricity than what PR used here. Ill give a whirl tonight and report back on the results..

Re: Retraction procedure

I wouldn't count on me not having appropriate tubing. I have several reels of Medical/scientific grade ptfe tubing. 1.9mm is not an issue as 1.9x2.3 is a pretty standard size. And the tubing I have has a much higher lubricity than what PR used here. Ill give a whirl tonight and report back on the results..

OK, but you will need 1.9 x 4. Also check the heat break to see if there's a chamfer inside or a straight ledge at the point where it transitions from 4 to 2mm ID.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Retraction procedure

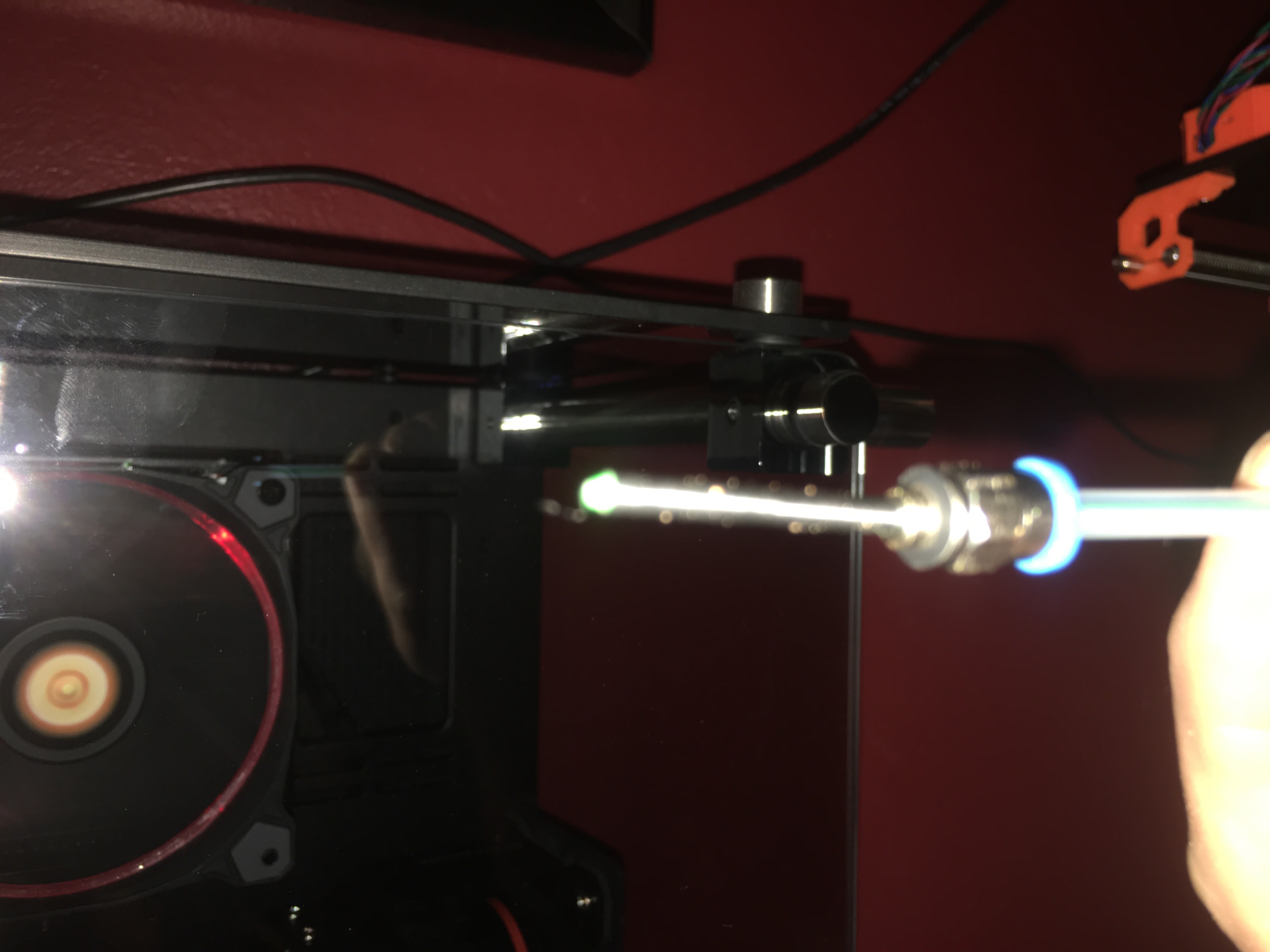

So I am a bit befuddled why I am ending up with a blob/clog on the end of the metal tube. See Pic attached. I had bought the MK2S for my youngest son. He is 16 and is terminally ill and we have been trying to let him experience as much as we can. We've done CNC machines, 3D printing, Drones and more. He so wants to get this working and be able to do colorful prints. So any ideas are greatly appreciated. Fairly soon we may uninstall the MM just so he can use it as a single filament system. Although I could just let him use one of my other printers while we sort out his.

Re: Retraction procedure

At what temperature are you extruding? I found that even the prepared MM sliced files were too hot and one of the filaments I was attempting to use would do something very similar. I am now extruding at 195-200°C - just 5° hotter than I would for single extrusion for a particular filament. It made all the difference.

The other thing is, if you are doing anything manually - like test extruding a filament, etc - you need to be very methodical in unloading the active filament before loading the next. I got bit by that once or twice as I was experimenting.

I'm sure you'll get it sorted.

cheers,

Michael

Re: Retraction procedure

I was using the examples as is. I guess assuming they would be perfect is a bad assumption. Ill try lowering the temps on them. Any recommendations on where to change that temperature to? I have been very meticulous with loading. I always unload all of them and load them before I try doing a print. Thanks.

Re: Retraction procedure

Michael

In the first post on this thread: http://shop.prusa3d.com/forum/original-prusa-i3-mk2-multimaterial-f26/blockage-troubleshooting--t4643.html you will find a temperature test cube. That will help you determine a good temperature for each filament.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Retraction procedure

There are 3 places you can change the extrusion temperature depending on what you are trying to do:

1) to slice new models, make the change in your slicer. For Slic3rPE it is on the Filament Settings->Filament panel: Extruder fields.

2) in an existing g-code file (from any slicer), open the file in a text editor. Near the top of the file you'll find the startup or prefix code section. Typically it will have an M104 "TTT" and M109 "TTT" - these set the extruder temperature. You may have 1 or the other or both as they do different things. So, do a global search and replace and substitute your new temperature for "TTT" for both M104 and M109.

3) simply change the temperature as the part is printing on the i3's display panel. You may have to constantly set to the new temperature depending on the g-code file.

Re: Retraction procedure

Thank you for the tips... Andrew and I have some time today and will experiment with temps and see if they help with this blob issue at the end of the tube. Also I took the bowden tubes off and measured them. The printer was set to 385mm yet each tube was 389mm long. Which is the correct length? Should I adjust in the firmware or cut the 4mm off or neither. Is there a document with the specs of each segment of the path? So far I know the hot end ptfe should be 41mm (mine was 39mm). I just want to make sure everything is accurate.

For instance on initial filament load the filament is stopped at 2/3 the way through the cooling/shaping tube. Is this the correct spot. It would seem to me that the initial load is vital so that the printer knows where the filament currently is. However it is extremely easy to mess up the loading since you could hold the filament at the entry point for a few seconds before acknowledging its there, thus it getting pushed even further into the tube. Maybe I am overcomplicating my view of this but I don't think so. Everything has to be pretty spot-on. Which I am ok with since I am an engineer but a 16 year old has a bit less tolerance for perfection, or at least mine does. lol.

Re: Retraction procedure

I don't know for a fact but the difference might be to account for the insertion into the PTC fittings. I would leave the alone. My tubes are the same length as yours and I'm printing fine now.

Re: Retraction procedure

No don't alter anything. You may find that you will eventually have to cut a few millimetres of the tubes if/when a Festo fails.

The initial load position is only approximate; the initial purge lines and filament changes are designed to be quite flexible and during a print it will sort itself out.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Retraction procedure

Sadly Andrew and I have come to the point where we have started using one of our other printers and shelved this one. The unit constantly jams. I think it may have been a bit premature for them to release it. But what do I know. I've only been 3D printing since 2010.. LOL.

Anyhow is there documentation somewhere with all of the specs of the tube lengths and whatnot so I can go through the whole setup and figure out what is wrong? Is there a source for a new PTFE tube with the chamfer and reaming all done by someone with experience in making them. I'm concerned that ours is too short at 39mm.

Any and all help is greatly appreciated by both of us.