Print quality problems [MM single mode + Hatchbox PLA]

Hi Folks,

Does anybody have any ideas about the following print issues?

This is Hatchbox white PLA printing at 210 (first layer) / 200 (other layers). [filament is rated at 180-210 deg C].

Layers are .2(1st-layer)/.3mm(rest).

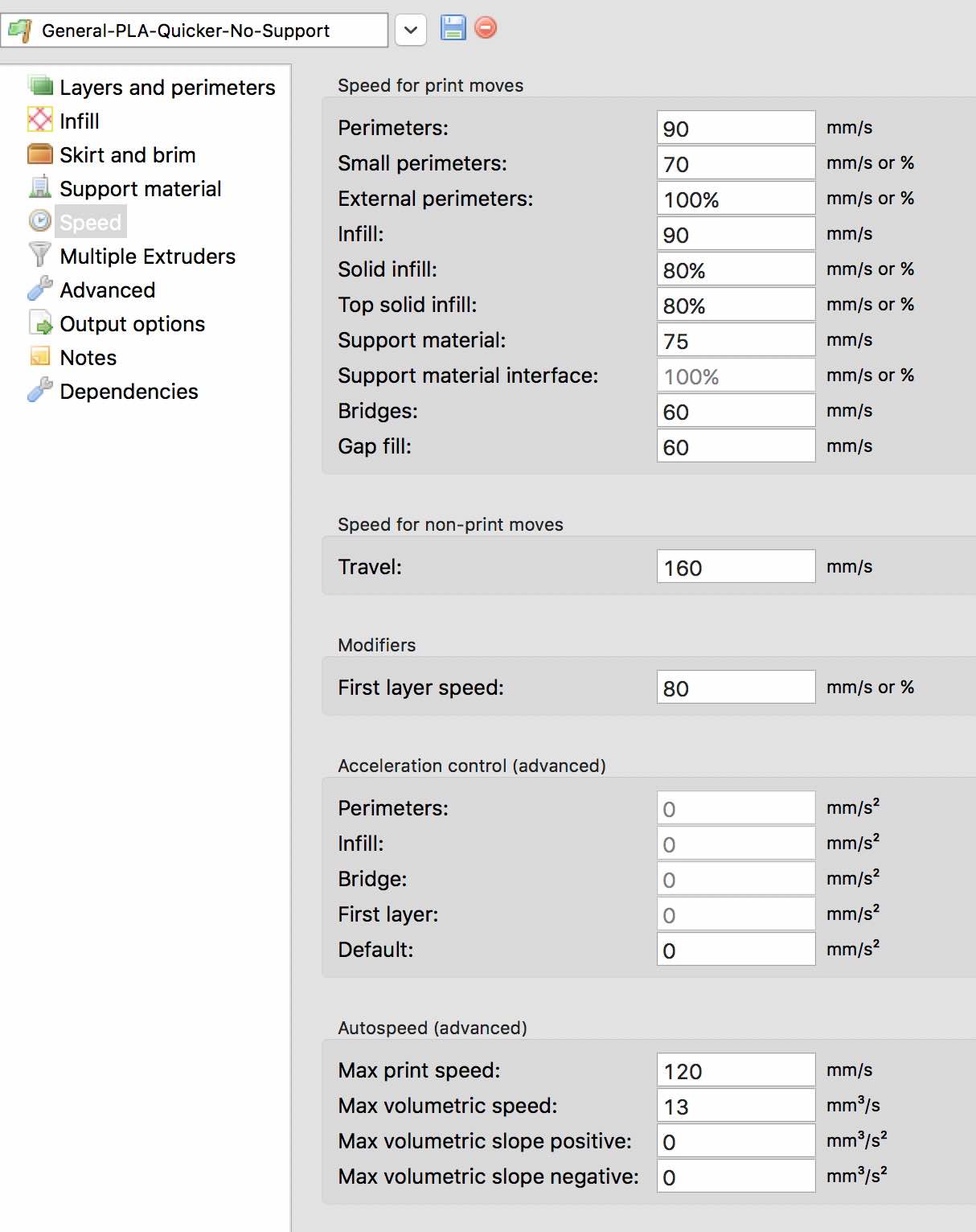

Speeds are as in the Slic3r-settings.jpeg image below.

Printer had about 110 hours on the original extrusion head and I've cleaned it with a cold pull and tools prior to print. If I push filament directly through the hot-end by removing the multiplexer, the filament comes out straight and appears smooth.

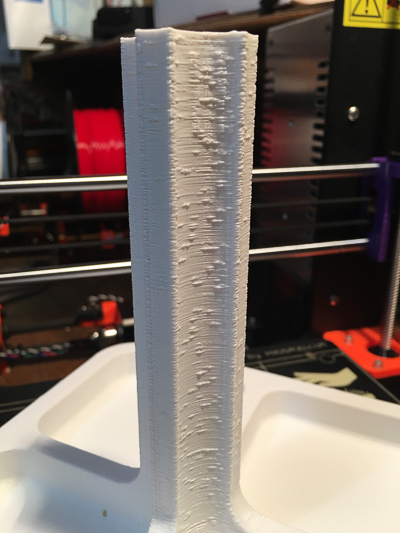

It seems like the blurbs are coming at the beginning of the layer.

I've already replaced the stock bearings on th XY sled since they failed at about 8 hours printing.

Any Ideas/suggestions?

What's your opinion about .3mm layer temperature with Hatchbox at 200 or 205 deg. C?

How long should a brass nozzle last? [This is the original brass .4mm e3dv6 nozzle with nothing but pure PLA printed.]

Thanks a bunch,

-Dave

Re: Print quality problems [MM single mode + Hatchbox PLA]

I’m confused why you mention the original hotend. Didn’t you switch the hotend for the new one with the MMU?

Re: Print quality problems [MM single mode + Hatchbox PLA]

Original hotend for the MM upgrade...I have the original MK2 hotend still in the box.

-D

Re: Print quality problems [MM single mode + Hatchbox PLA]

Hi Folks,

Does anybody have any ideas about the following print issues?

This is Hatchbox white PLA printing at 210 (first layer) / 200 (other layers). [filament is rated at 180-210 deg C].

Layers are .2(1st-layer)/.3mm(rest).

Speeds are as in the Slic3r-settings.jpeg image below.

Printer had about 110 hours on the original extrusion head and I've cleaned it with a cold pull and tools prior to print. If I push filament directly through the hot-end by removing the multiplexer, the filament comes out straight and appears smooth.

It seems like the blurbs are coming at the beginning of the layer.

I've already replaced the stock bearings on th XY sled since they failed at about 8 hours printing.

Any Ideas/suggestions?

What's your opinion about .3mm layer temperature with Hatchbox at 200 or 205 deg. C?

How long should a brass nozzle last? [This is the original brass .4mm e3dv6 nozzle with nothing but pure PLA printed.]

Thanks a bunch,

-Dave

slic3r-settings.jpg

PLA-prob001.jpg

PLA-prob002.jpg

The main thing I'm curious about is that this happens at the beginning of each layer. Judging by the style of your print, it doesn't look like each layer has points where it would pick up/set down, but would probably print the whole layer consecutively, then only pick up and set down between layers.

My guess is retraction length/speed? It wouldn't hurt to try turning down the temp a little, but I'm guessing it is between those two things (temp/retraction settings)

As for the nozzle, I don't think that has anything to do with your problem, the nozzle should last a long time with only PLA prints.

Re: Print quality problems [MM single mode + Hatchbox PLA]

I'm not 100% sure the blobs are at the start of each layer. The time lapse is too fuzzy for me to tell. Retraction settings were unchanged from the default Slic3r MM-Single-Filament settings in the latest Slic3r update from Prusa. Layer start was 'Random'. I left the temperature a bit on the warm side for better layer adhesion given the tower is a weak point in the design.

-D

Re: Print quality problems [MM single mode + Hatchbox PLA]

I'm having the same problem with Hatchbox white. I've gone as low as 180 c, still poor quality prints. Before MMU it was my "go to" white. I haven't changed any retraction settings, as I'm not sure what to do there.

Re: Print quality problems [MM single mode + Hatchbox PLA]

I'm trying fiddling around with the retraction settings first, then the temp settings to see if I can get to it. There's a comment on the blog below discussing possible differences between bowden setup and regular.

http://louissimons.com/blog/retraction-calibration

I'm using that same calibration button to iterate.

slic3r has settings for 'wipe while retracting' and 'retract amount before wipe' so if nothing comes of just the retraction length and PLA temp then I'll fiddle with that.

-D

Re: Print quality problems [MM single mode + Hatchbox PLA]

Follow-up:

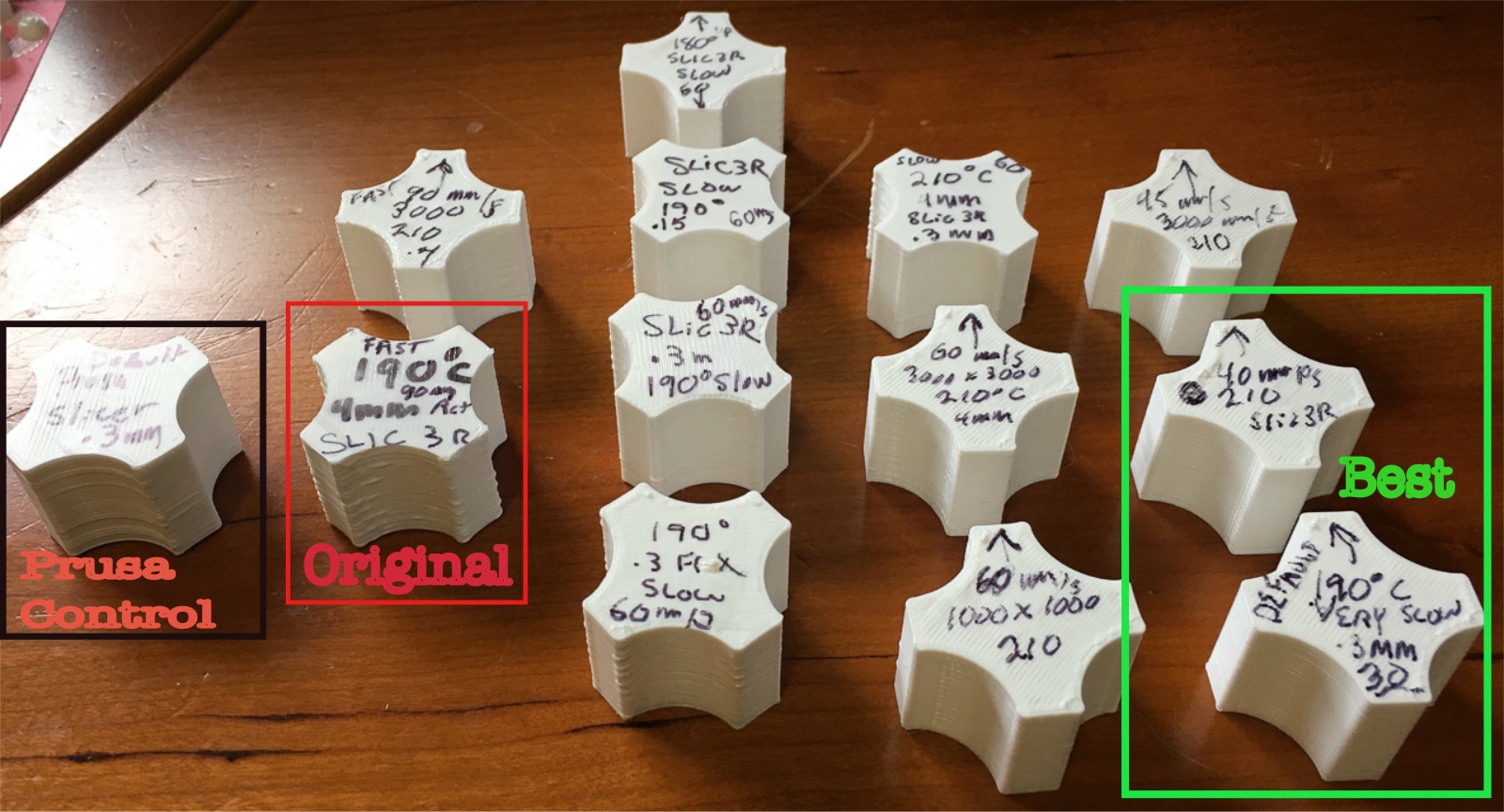

I did a handful of experiments to see if I could get the Hatchbox White PLA to print better. This proved successful. Here's what I found. I hope someone will find this useful. See the images Attached.

For the impatient.: net-net: Use Slic3r, not Prusa Control. Start with "0.2mm NORMAL" Print Setting. Keep the perimeter print speed way down (30 or 40mm/s), make sure you have Acceleration control set to a low (say, 1000mm/s2 or lower) value. Leave the nozzle temp hot (210) since that works fine.

Summary for the slightly less impatient [Caveat emptor - you're mileage may vary]

Slicer used: Slic3r [Prusa Control showed some pretty bad layer shifting using the Draft default settings and i've not investigated why]

Retraction Setting: 4mm, Retract on Layer change.

Acceleration: Added "M201 X3000 Y1000" to Printer Settings Start G-Code - Alternatively, just set1000mm/s2 for all Acceleration Print Settings.

Speed: 40mm/s [perimeters]

Temp: 205-210 [arbitrary]

Layer height: .3mm tested [.15 also works nicely].

Tests:

Initial Conditions:

Printer: Prusa i3Mk2 with MM upgrade

Firmware : 3.1.0 (November 12, 2017)

Slicer: Slic3r 1.38.6-prusa3d version

Starting Profile: "Original Prusa i3 MK2 MM Single Mode"

Adjustments/Experiments:

-Filament Extrusion Multiplier (Calibration): No change. a 100mm extrusion commanded from Octoprint was exactly 100mm (you have to remove a Bowden tube to do this)

- Retraction Length: This setting doesn't matter much between 4mm and 6mm. I played around and incremented retraction settings at 0mm,4,5,6,7 and 10 mm. at 7mm, things worsen and 10mm retraction shows significant degradation of print quality -- Conclusion - Keep standard 4mm.

-Retract on Layer change: Very slight difference between no-retract and retract with a nod to Retract on Layer Change -- Conclusion - Use retract on Layer Change.

-Temperature: varied between 180 and 210. No significant difference in print quality except that at 210, top layers will flow a bit too much for a clean look. I eventually just left the nozzle temp at 210 and added an extra top-layer (Top Layers = 3), in order to keep the layer bonding as good as possible.

-Perimeter Speed: This makes the most print-quality difference and is influenced by acceleration settings. I started out with 90mm/s which was working on the i3Mk2. This is way too fast for the Hatchbox PLA and a bit ambitious anyway. I slowed the print to 60mm/s, then 30mm/s and 45mm/s and eventually settled on 40mm/s as optimal. If you take the "0.20 NORMAL" print settings and and change the layer height, it should work fine.

-Acceleration: This has a big effect on the output quality but was not as dramatic as simply lowering the speed to 30mm/s. Notice that most of the the various Print Settings in Slic3r have default acceleration set to 1000 for low-res prints and this seems like a good value. The default firmware acceleration setting as reported via Octoprint is 9000 and the really misleading thing in the Slic3r Printer Settings > Speed > Acceleration Control settings is the Mouse-over text in the first field that reads "A high value like 9000 usually gives good results if your printer is up to the job". I added the following custom setting in Printer Settings > Start G-Code to set the X,Y independently : M201 X3000 Y1000. However, it really doesn't matter much as long as you just keep the 1000mm/s2 value as the default in the Print Settings and call it good. -- Conclusion - Set default acceleration to 1000 on all print settings to override the default 9000mm/s2.

Other observations:

-You can occasionally hear the PLA make a crackling sound and i'm wondering if that's one of the issues causing random blobbing on straight sections of the print.

-Acceleration settings are seen at the corners since they have the most abrupt speed changes for X and Y. Watch the corners as you tune the acceleration settings.

-At higher speeds you may lose steps causing a layer shift and ruining your print. I've seen this a handful of times on the i3Mk2 and if anybody knows how to quantify this, I would appreciate some feedback.

Re: Print quality problems [MM single mode + Hatchbox PLA]

I just want to say thanks for posting such fantastic results and explanations. Everyone hates googling a problem only to find a "n/m problem solved" with no explanation.

Re: Print quality problems [MM single mode + Hatchbox PLA]

Thank you very much for the extensive work you have carried out and the tips. Can you post the file that you have used (or the link to thingverse, if it can be found there)?

I really would like to improve my prints as well and will use your adjustments as a starting point for my tests.

Re: Print quality problems [MM single mode + Hatchbox PLA]

Hi David,

thanks a lot as well - very informative. Can you help me to understand your statement on Acceleration?

-Acceleration: This has a big effect on the output quality but was not as dramatic as simply lowering the speed to 30mm/s. Notice that most of the the various Print Settings in Slic3r have default acceleration set to 1000 for low-res prints and this seems like a good value. The default firmware acceleration setting as reported via Octoprint is 9000 and the really misleading thing in the Slic3r Printer Settings > Speed > Acceleration Control settings is the Mouse-over text in the first field that reads "A high value like 9000 usually gives good results if your printer is up to the job". I added the following custom setting in Printer Settings > Start G-Code to set the X,Y independently : M201 X3000 Y1000. However, it really doesn't matter much as long as you just keep the 1000mm/s2 value as the default in the Print Settings and call it good. -- Conclusion - Set default acceleration to 1000 on all print settings to override the default 9000mm/s2

Below are the settings that I find in my Prusa Slic33r (same version that you have shown):

I cannot find anything like 9000 in there - only 800 for the perimeters and 2000 for the infill - the rest is set to 1000. Is the figure of 9000 due to OCTOPRINT? Which value should I use on the perimeter?

Thanks a lot

Re: Print quality problems [MM single mode + Hatchbox PLA]

"thanks a lot as well - very informative. Can you help me to understand your statement on Acceleration?"

Sure,

When you use any slicer, that along with the firmware will have a set of parameters used for printing. If the value was not set in the slicer, then the value would be the default set in the firmware which you won't see in your input file [G-code plus some name-value pairs of parameters. But...you can just ask the printer "what settings do you have" with the M501 command and the printer will tell you.

To do this, you need some way to send commands directly to the printer and view the output In the image below. I'm using Octoprint's Terminal feature to send commands directly to the printer. Alternatively, you could use Pronterface.

Take a simple G-code output from Slic3r, fiddle with the settings, then open the gcode file in a text editor (notepad, vi, nano, whatever..) and you will see what Slic3r or any other slicer doing to control the printer. The confusing thing is that it's not straight G-code- -- Slic3r piles the variables like acceleration settings into name-value pairs like "; default_acceleration = 0;". To know how that translates in to G-code, you'd have to do that M501 (show the settings) after the print starts -- it looks like those name-value pairs are parsed in the printer [caveat, i'm pretty new all this 3D printing jazz so I'm just stating what I'm observing]

Here's a good reference: http://reprap.org/wiki/G-code#M503:_Print_settings

Look for the commands that work with "Marlin" firmware as that's what Prusa is using, or a variant thereof. Any of those could be sent to the printer directly over Pronterface or Octoprint Terminal.

-D

Re: Print quality problems [MM single mode + Hatchbox PLA]

"Thank you very much for the extensive work you have carried out and the tips. Can you post the file that you have used (or the link to thingverse, if it can be found there)?"

That chunk I was using worked ok but does use a bit of filament. I also created another test pattern with columns and corners which i've posted:

https://www.thingiverse.com/thing:2759741

-D

Re: Print quality problems [MM single mode + Hatchbox PLA]

I just want to say thanks for posting such fantastic results and explanations. Everyone hates googling a problem only to find a "n/m problem solved" with no explanation.

You're welcome 🙂