Deformed PTFE liner tip and removal trick

If your MM upgrade has gone anything like mine has you have had a few jams.

I have taken the PTFE liner out a few too many times and I managed to deform the top half a little bit. This was adding some lag to my retracts.

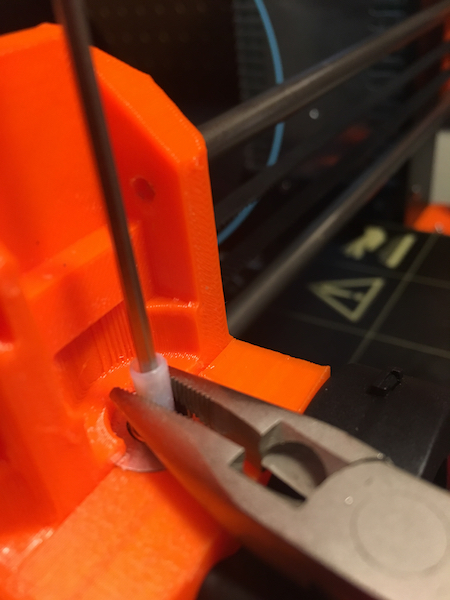

So to fix it I stuck in a 2mm ball end wrench about half way through and twisted it around a few times to round out the top half again. now its smooth retraction again.

Now if I have to remove it again. i insert the wrench first, depress the release and pull it out.

I know its not exactly Ideal, But I don't have any of this fancy high precision PTFE liner lying around to just replace it with and it still mates with the heat break fine. I think Prusa should consider including a spare.

If anyone has any better ideas or a way to remove the tube without deforming it, I would love to hear it.

Happy MM Printing 😀

Re: Deformed PTFE liner tip and removal trick

I don't understand what is causing your problem which requires the PTFE removing, but FWIW when I need to remove it, I use round nose pliers when it's too tight to remove by hand.

However, I have found that unscrewing the heat break half a turn, inserting and locking the PTFE tube then tightening the heat break helps ensure there is no gap between the two where soft filament can get stuck.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Deformed PTFE liner tip and removal trick

pushing down too hard to clear a jam and breaking the filament so its flush with PTFE liner 😳

thanks for the tip