blocking of filament

Hello guys

My Prusa MK2S, which has generated a 100% successful printout so far, has now become an object of disappointment, if I had to rate it now it would probably only get 0 stars out of 10.

I've been installing the Multi Material Update for 10 days now, but I haven't been able to finish a successful print yet. The problem is that the further transport of the filament is blocked after the cleaning has been carried out successfully.

To reiterate it in detail:

1. Bedleveling ok

2. Cleaning of nosel ok

3. Actual printing starts Filament feed is blocked.

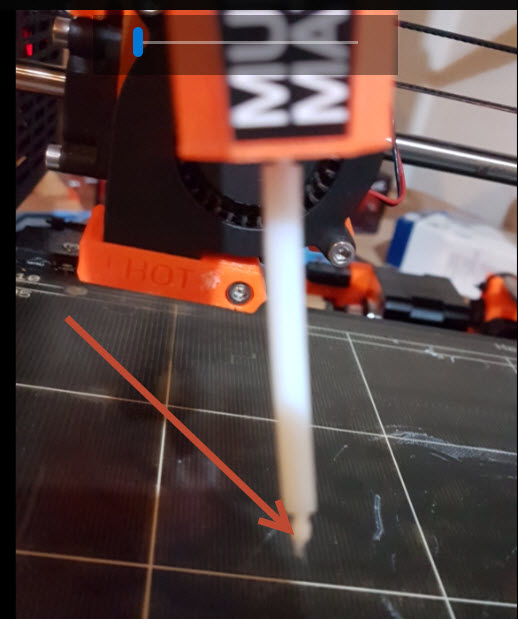

If I disassemble the multiplexer after point 3 during printing, it looks as follows. The blob you see happens with every retract.

See attached Picture.

Depending on the material, this is more or less large. With ABS it happens that the pressure starts and then stops apprupt because there is no filament, with PLA (original prusa) it always blocks immediately.

It doesn't matter if I use my own objects slice or pre-sliced models.

I tried all the tips in the forum without success.

I should definitely have a solution, otherwise I have to rebuild it because I need to print some prints.

Any Ideas?

Martin

Re: blocking of filament

I had similar issuez. Sounds counter intuitive... but Try reducing extractiion to 1.5mm...

If it allows you to print with a little stringing.

You can develop your settings afterwards.

I initially tried elevated temperatures. But this lead to massive stringingissues and barely improved peinting between nozzle clogs.

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: blocking of filament

Hi,

Actually I am using PrusaControl, there is no way to change a setting in the tool

I tried almost everything, 4 color prints, 3 colors, 2 colors as well and also 1 color without switching to single mode, and off course as well the single mode, always the same result of blocking filament.

I also tried Slicer Edition and was playing almost with all of the retraction paarmeters. No way to get it work. (latest Version of Slicer, and yes I have the correct Firmare installed :-))

At the moment I am so dissapointed with this bad quality of Upgrade, my expection is build it and then use it, and not like now build it and put it to trash 🙁

I have created also a custom support request, I hope they will come back soon with a solution.

But all tips are welcome, I will try for sure.

Re: blocking of filament

have you tried printing the Pre sliced models?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: blocking of filament

of course as I wrote in my first entry it does not matter if I used a pre-sliced model or my own sliced ones, result is always the same, blocking of filament flow.

Martin

Re: blocking of filament

You are not very descriptive in what you have tried, so this is a shot in the dark.

The fact that your PTFE tube came out of the cold block and is stuck to the Y block tells me the PTFE tube was not correctly seated in the cold block.

You have to back the nozzle out, heat the heat block, insert the PTFE tube, and then tighten the nozzle to make sure it has a water tight seal between the nozzle, heat block and cold end. The PTFE tube must be tapered correctly to prevent blockage.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: blocking of filament

Hello Aaron

On your assumptions that the PFTE Tube was not used correctly I can say with a clear conscience that the PFTE Tube has the correct length of 41 mm and is adapted accordingly. It is installed correctly, if this would not be the case the multiplexer would not fit.

In order to take the photo, I pulled out the PFTE tube manually.

As I have already mentioned, I have implemented all the mentioned tips from the forum, I have checked the metal tubes several times, the correct fit of the PFTE tube, smoothness of the filament feed and and and and.....

I spend more than 40 hours to get it work.

None of the listed tips have removed the blockade, I don't want to say yet that there is a bad design here, but it looks more and more like this.

I have been waiting for days now for an answer from Prusa to my question, but no answer yet.

In the meantime, I have rebuilt my printer back to single (1 hour needed) and got the same quality as before.

Martin

Re: blocking of filament

Hey,

still facing with the exactly same issue of clogging directly in front of the PTFE tube after upgrading to MM

What I have tried so far:

- Reassembly of the hot-end -> seems okay

- Recheck if the PFTE tube is assembled properly -> set the whole way in with no backlash

- Recheck if the nozzle is assembled properly -> finally tighten with temperature > 240°C

- Fine-tuning of the extruder tension to avoid squeezing of the filament -> tried settings between 8mm - 5mm (as recommended)

- Use of PTFE spray for better filament transport -> looked better, but just for a short moment

- Test of different hot-end temperatures from < 200 °C to > 240°C -> normal temp for PLA not able to run -> no clogging with temp > 235°C

- Test of different Slicer software like "slic3r" or "Simplify3D" -> no difference

- Test with pre-sliced MM gcode and single extruder gcode -> seems to work for some layers but suddenly starts with clogging

ACTUAL SOLUTION:

I have changed back the complete (new) hot-end to the original one that came with my Prusa i3 MK2S !!!

After doing Live Z adjustment I printed the 3d benchy WITHOUT ANY CLOGGING so far!!!

Next test is the MM 4color bearing!

I would like to understand the difference between the original hot-end and the one which came with the MM upgrade?!

Thanks for any comment and support!!

br Dirk

Re: blocking of filament

Just a quick update, I had contact with support yesterday, they are asuming that something is wong with the PFTE Tube and they will send a new one. As soon I have it I will give it a try a will post an update.

Martin

Re: blocking of filament

I’m already very disappointed to read about that clogging issue in various threads inside that forum and Prusa obviously has still no solution for us!

After changing back to the new MM hotend the problems continued!

Re: blocking of filament

It looks like your filament has grooves on it where the extruder gears grabbed it. That might indicate that you have the tension set too tightly on the extruder, and the deformed filament is catching in the hotend. The single color version did this too if you had the tension too tight.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: blocking of filament

The spring tension is exactly set to 5mm between body and washer - so as recommended by Prusa.

I‘ve tried already lower tension but unfortunately with the same result in clogging in front of my PTFE tube. Actually I‘m facing on the question if my PTFE tube fits properly into the hotend or not?!

Test Print ist Running...

Re: blocking of filament

I am Sorry to be so late, but until now I was not able to try it out with the new PFTE Tube, I will do my best to reassemble my Printer next week.

Martin