Ninjaflex and the Extruders

I was messing around with some Ninjaflex today and while watching it spool out of the side of the extruder (which admittedly was running too fast) I wondered why there was space in the extruder design to let this happen at all? Is there a reason why the extruders are not more enclosed so filament can't escape? I realize this isn't usually an issue, but I wondered if there was some reason for this specific design?

Just curious. Thanks.

Re: Ninjaflex and the Extruders

Just guessing here, but installation of the drive gear is pretty difficult already without making less access space.

I think they also need some air movement to prevent the drive gears overheating - heat from the motors will creep down the spindle; any more than 50 degrees and the filament will start to soften.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Ninjaflex and the Extruders

Not sure about the heat argument. If you look at the structure of the Bondtech QR extruders, there's not much airspace in them. I may tinker with the current extruder design to see if I can come up with something with better filament support.

Re: Ninjaflex and the Extruders

Not sure about the heat argument.

I am. the extruders can get quite hot, especially when printing a 2 filament model with many and frequent changes.

The extruder current is increased significantly during changes and there is a build-up of heat which passes along to the spindle and drive pulley.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Ninjaflex and the Extruders

The heat problem could be solved with some heatsinks on the motors, if that means I get to print flexibles more reliably, I gladly take the added cost of 4 heatsinks and possibly fans.

@tim.w If you come up with a design, I would be intersted in trying it 🙂

Re: Ninjaflex and the Extruders

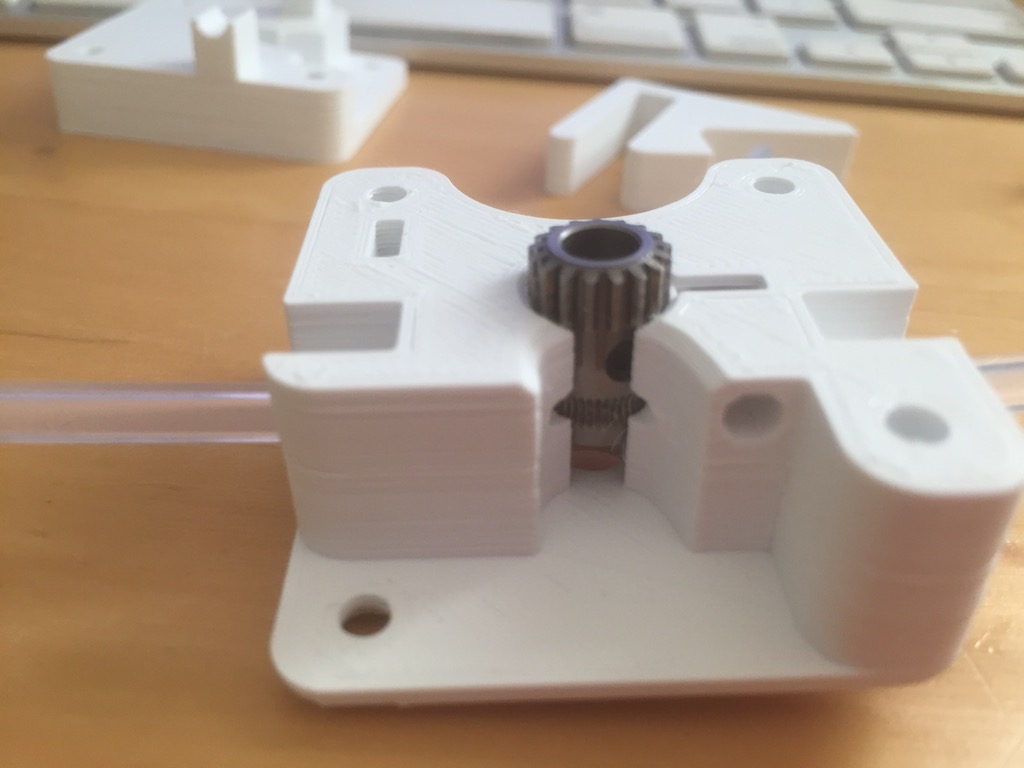

So for the fun of it I redesigned the extruder based on the internal design of the BondTech QR extruder (which I happened to have kicking about). The spacing around the drivegears are greatly reduced leaving unsupported filament only where the gears mesh. I've attached a few pictures:

However, while this works just fine as a normal extruder, and while it pushes the NinjaFlex much more effectively without it getting snarled up inside, it still doesn't seem able to provide the pressure necessary to push it down the bowden tube and out of the hotend.

Any thoughts? The BondTech QR uses 3:1 gearing to increase the torque so I'm wondering if the bowden is just too long and the NinjaFlex too compressible without something like that.

Re: Ninjaflex and the Extruders

So I tried shortening up the bowden tube (held the extruder about the multiplexer by hand and connected it with a tiny piece of ptfe) but still no joy. Possibly it just doesn't like the pathway though the multiplexer because the forces aren't pushing the filament directly into the hotend?

Re: Ninjaflex and the Extruders

1. Very nice design. Well done.

2. Do you have the filament tension too high? Softer filaments need very low tension otherwise they don't release from the drive gears.

3. There has to be a way for it to work - and I don't think any reduction gears are necessary. There's plenty of pushing power available - maybe too much?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Ninjaflex and the Extruders

So I tried shortening up the bowden tube (held the extruder about the multiplexer by hand and connected it with a tiny piece of ptfe) but still no joy. Possibly it just doesn't like the pathway though the multiplexer because the forces aren't pushing the filament directly into the hotend?

Could you elaborate a bit on exactly what is happening that makes it not work?

Can you get any filament to come out of the nozle?

Does it fail after some layers?

I did some tries with recreus filaflex and it did extrude 5 or 6 layers before getting twisted around the extruder.

But I only later noticed that the flexible material presets in slic3r do not influence the retraction settings in the printer settings, which were 80mm/s and much too high for flex.

Could you upload your extruder somewhere, I'd ike to try it again with the more constrained filament path.

Also, I know its harder to model, but we have 3d-printers so we can do stuff that normaly would not work in other manufacturing methods, specifically, if you were concerned about cooling, you could make the extruder gear housing a "swiss cheese" with straight air ducts going through the whole thing so there is some air flow?

Re: Ninjaflex and the Extruders

Well the extruder did seem to push the ninjaflex down the ptfe tube much more effectively than the original extruder. When loading the filament using the original, the ninjaflex would always be a few centimeters short of the y-splitter, but with the new extruder the ninjaflex would load into the splitter just like any other filament. This seemed encouraging. However, I could not get it to come out of the hotend. Occasionally a bit would sort of extrude, seemingly at random, but not in any useful way. So I never got to extruder any layers. That said, I never got it looped around anything either - it just seemed to get compressed in the tube and splitter and not go anywhere.

Interesting that you got the recreus filaflex working even a bit considering its even softer.

As for changing the extruder - I'm not sure where to go with it to make it better since it seems to be pushing the filament, but the filament won't go anywhere. There could be something else going on with the printer (I had the blockage from hell yesterday) which is causing trouble. I'm not concerned about cooling since the BondTech QR extruder I've used for inspiration is mostly enclosed and they seem fine with heading/cooling.

You can find the model on Onshape here - https://cad.onshape.com/documents/86101f4006840a222a16a165/w/d26df690bd31abbf56d497d0/e/b2f93d7a6a796380abdb084c

Re: Ninjaflex and the Extruders

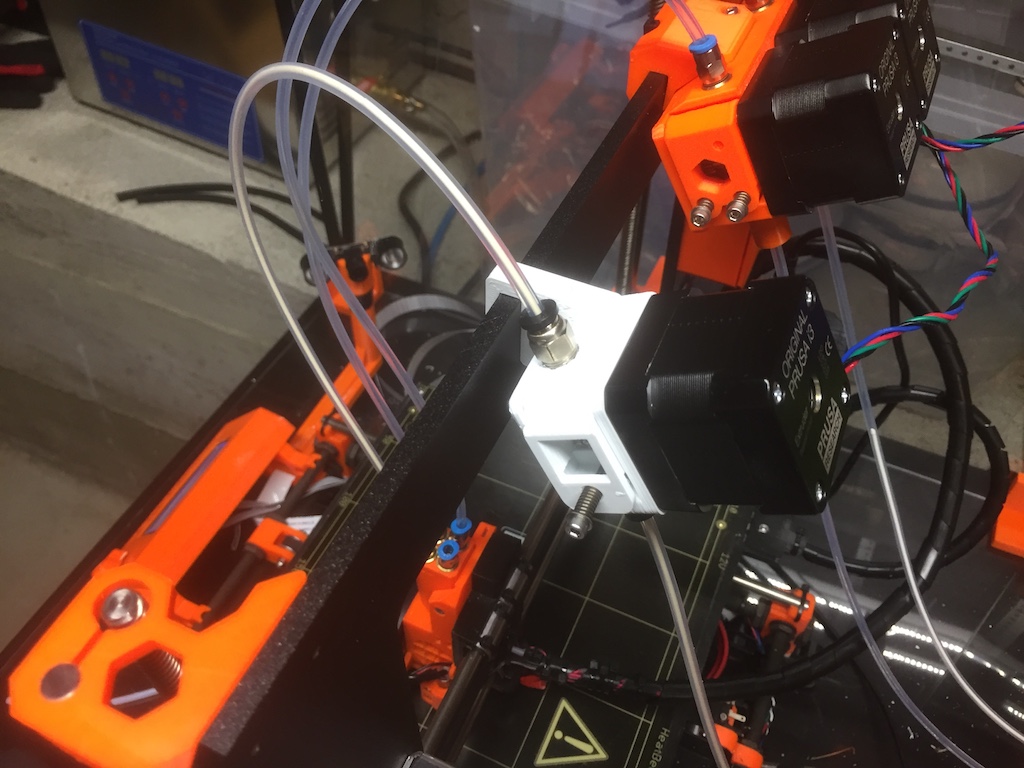

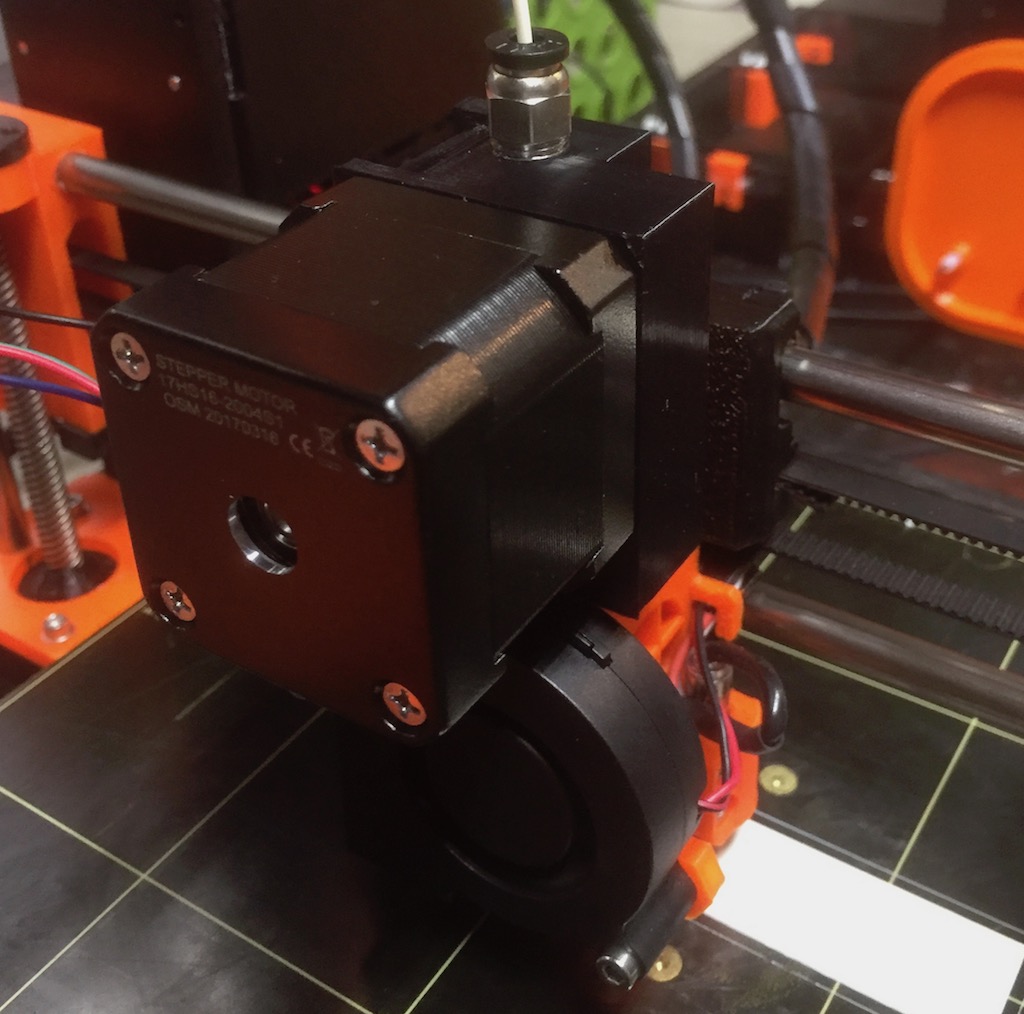

Okay - because I want to print ninjaflex again, I really don't want to buy another 3d printer, and I don't want to give up the multi-material option, I decided another approach was to design a new direct drive extruder. I don't want to convert the printer back to its pre-MM days, I just want to quickly switch it to a direct drive extruder when I need it. So my new extruder is shaped to fit into the same gap as the y-splitter and bolt to the frame in the same way. To install you simply remove the y-splitter and attach the direct driver extruder. I have it wired as extruder 4.

Here's the first prototype:

It's based on the same design I tried for the other extruder, but here its used to directly drive the filament straight into the hotend.

And here's my first print using NinjaFlex:

I printed the NinjaFlex at 240C, 40C bed and ... accidentally ... printed it at the default speed (40mm/s). But it came out rather well I thought.

Re: Ninjaflex and the Extruders

Thanks for the onshape link!

Also, I love the extruder switch idea. could you post that too?

An easy way to switch between MMU and standard mk2s would be the perfect world for me.

Re: Ninjaflex and the Extruders

Here's the Onshape link for the direct extruder. I'm still tinkering with sizes and clearances on this and on the previous extruder. Also, on this new one, I accidentally created it as a mirror of what I really wanted (you have to plug the stepper in backwards!) so you'll find the mirror version (*not* the one to use) and the non-mirror (use this one) on Onshape. When you install this extruder in place of the splitter, there's a gap between the top of the ptfe sticking out of the hotend, and the drivegear inside the extruder - I think it's about 10mm. You need to push a bit of ptfe tubing into the extruder to give the filament a smooth path down to the hotend.

Re: Ninjaflex and the Extruders

Also - because this is fun - I decided to build a hybrid bowden/direct multi-material extruder. This attached the splitter to the top of the direct extruder:

The goal here is to allow me to print with multi-materials, including ninjaflex. The direct drive stepper takes care of making sure the softer stuff extrudes correctly, while the splitter and bowden steppers take care of moving material into the splitter. In theory at least, I can switch materials just like the original MM design, but have the advantages of a direct extruder.

A couple of interesting things to note while testing this. First, I realize I'm going to have to mess with the Slic3r code because the distance to unload/load when switching materials has increased (maybe its easily configurable somewhere?). Second, The original MM electronics came with a spare 4-pin socket which lets you plug a stepper directly into the stepper signal coming in from the Rambo board. That means, in theory, its easy to run the direct stepper whenever any other extruder stepper is running (since that stepper signal is common to all); and that's what we want. I notice the new MM electronics don't have spare socket anymore. Third, I realize I'm running two steppers in parallel off the stepper drive. Since this is what the Rambo does for the y-axis I figure this isn't a problem. However, I can only get the new Prusa steppers (the ones that came with the MM upgrade) to play well together. If I try to use the original extruder stepper, or another random stepper I have, then they start skipping. Not sure why yet.

Here's the ninjaflex test, again at full speed:

Re: Ninjaflex and the Extruders

I realize I'm going to have to mess with the Slic3r code because the distance to unload/load when switching materials has increased (maybe its easily configurable somewhere?).

The only thing that's configurable is the length of the Bowden tubes (firmware reset to set this) but that won't help, because the additional length is after that point.

You do have the option of using KISS and my post-processor, where you can configure the load/unload distances, or you could edit all the output G-code files.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Ninjaflex and the Extruders

That seems to be very interesting. How do you adjust the Setting when you change from multi Extrusion to single? I am thinking about to use the third extrusion motor for your single Extrusion Setup. Because I do not really see the need in printing multicolor.

Re: Ninjaflex and the Extruders

I'm really interested in the MM upgrade, but mostly to be able to integrate hard+flex+scaffolding into a print - as opposed to colors. Adding a direct extruder pretty much makes this the "perfect" MM printer for any combination of materials, to the point of competing w/idex.

Re: Ninjaflex and the Extruders

That seems to be very interesting. How do you adjust the Setting when you change from multi Extrusion to single? I am thinking about to use the third extrusion motor for your single Extrusion Setup. Because I do not really see the need in printing multicolor.

For the single extruder I'm basically loading the filament into it by hand; or more specifically by pushing button in an OctoPrint window to gradually load the filament into the extruder. Then I just print as a single using gcode generated with a single extruder profile with a little but of gcode added to select my single extruder at the beginning of the print.

Re: Ninjaflex and the Extruders

I'm really interested in the MM upgrade, but mostly to be able to integrate hard+flex+scaffolding into a print - as opposed to colors. Adding a direct extruder pretty much makes this the "perfect" MM printer for any combination of materials, to the point of competing w/idex.

I started down this path, at least in part, because I wanted to print flexible and support at the same time. The combination of direct drive and multiple filament is probably the most flexible setup but requires the most changes to software and firmware to get working.

Re: Ninjaflex and the Extruders

Had chance to tweak some gcode today to try to run a multi-material print with the hybrid arrangement ... and it's going go need some more work. What happens (and I worried it would) is that during retraction to change filaments, the soft retracting filament gets squeezed by the direct drive gears and blocks the extruder. Obviously its still too soft to extract at that point. I've been fairly simplistic in how I'm handling this so far but it looks like I need to consider letting the filament cool in the cold part of the hot end a little longer; and maybe there are side effects with doing that.

The current unload retraction is split into several bits, looking like this:

G1 E-15.0000

G1 E-50.0000 F5400

G1 E-15.0000 F3000

G1 E-12.0000 F2000

I wondered if anyone (looking at you PJR) could break down exactly what each distance and speed corresponded to and why. I'm sure this was extensively tweaked during beta.

Thanks

I'm really interested in the MM upgrade, but mostly to be able to integrate hard+flex+scaffolding into a print - as opposed to colors. Adding a direct extruder pretty much makes this the "perfect" MM printer for any combination of materials, to the point of competing w/idex.

I started down this path, at least in part, because I wanted to print flexible and support at the same time. The combination of direct drive and multiple filament is probably the most flexible setup but requires the most changes to software and firmware to get working.