Re: Ninjaflex and the Extruders

Aaaand ... turns out that I just messed up my tweaked retraction code and wasn't correctly including the length for the direct drive part. Fixed that and I got my first "dual" color print. Except, for this test one of the colors was an empty extruder (just in case it went wrong). Hope to do a proper dual color test in the next few days. But looking promising again.

Re: Ninjaflex and the Extruders

The current unload retraction is split into several bits, looking like this:

G1 E-15.0000

G1 E-50.0000 F5400

G1 E-15.0000 F3000

G1 E-12.0000 F2000

I wondered if anyone (looking at you PJR) could break down exactly what each distance and speed corresponded to and why. I'm sure this was extensively tweaked during beta.

Yeah. I wonder why those distances and speeds too. 😉

I use a slightly different unload strategy in my post-processor and the strategy I use depends on the filament type (you can't retract so fast with a soft filament - it just stretches). I also adjust temps to increase the unload/purge effectiveness.

1. Get the filament out of the nozzle and into the heat break

2. Pull through the PTFE tubing

3. Into the MUX and round the bend

4. Into the cooling tubes

The distances didn't change a lot during testing (minor adjustments) it was getting the speeds right whilst remaining within the limits of the motor/MCU.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Ninjaflex and the Extruders

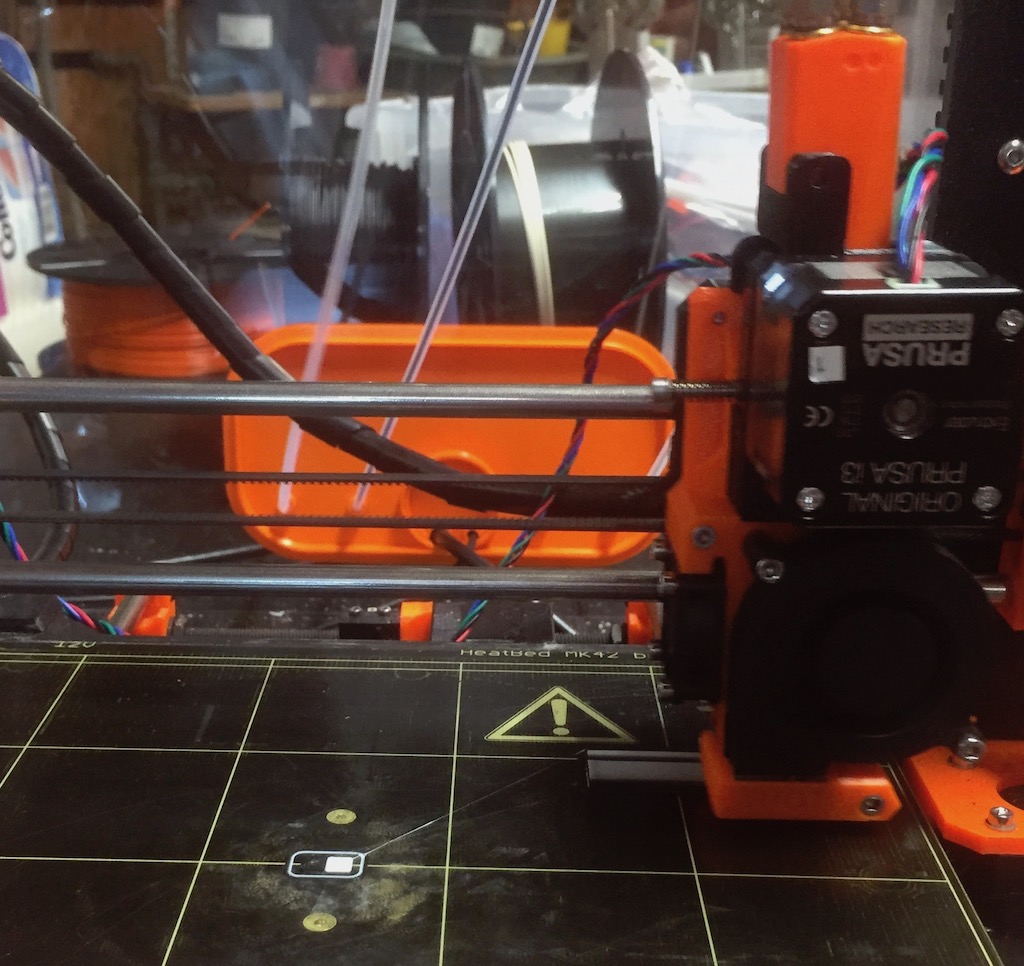

My quest for the hybrid extruder system continues. Today I had it printing a 2-color print - black and white PLA. Some new changes were necessary to make this work. First, I needed to slow the speed it retracts the filament through the heatsink to allow it to harden. If I didn't, it would often get smushed by the bondtech gears in the direct drive extruder. Second, I needed to switch out the ptfe liner from the hotend. I had hoped to leave the original in place and just supplement it with extra bit of tubing inside my new direct drive extruder. However, this proved unreliable so I replaced it with a new, cut to size, 1.8mm/4mm ptfe tube. And, with both these changes, I just completed my first tiny test print:

And here's the shape of the filament ends once its completed:

Because I'm cooling the filament in the hotend heatsink I'm curious of the metal tubes serve any purpose in this setup. I might build a new hybrid extruder which does away with them just to see. I also have to test this with flexible filament (which was what set me on this path in the first place).

Re: Ninjaflex and the Extruders

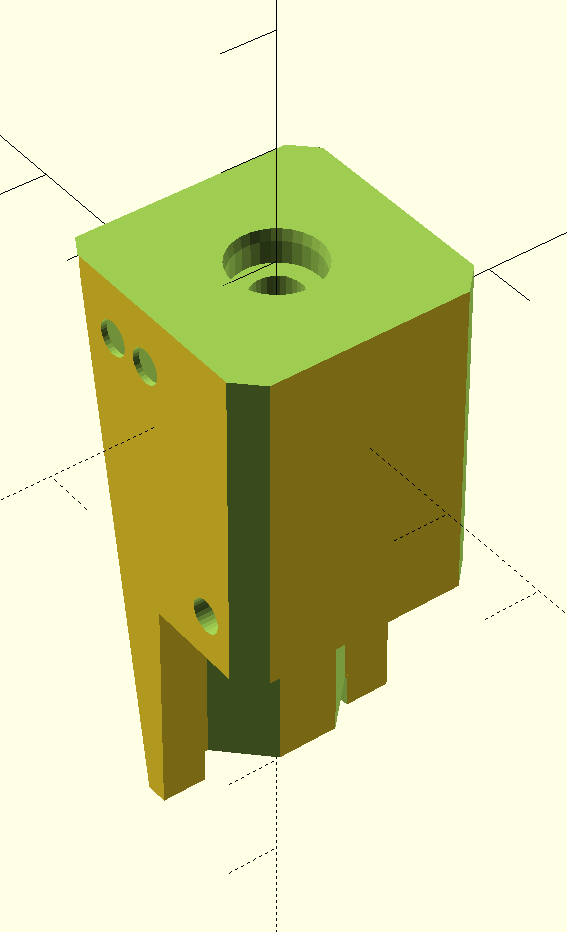

Okay - because I want to print ninjaflex again, I really don't want to buy another 3d printer, and I don't want to give up the multi-material option, I decided another approach was to design a new direct drive extruder. I don't want to convert the printer back to its pre-MM days, I just want to quickly switch it to a direct drive extruder when I need it. So my new extruder is shaped to fit into the same gap as the y-splitter and bolt to the frame in the same way. To install you simply remove the y-splitter and attach the direct driver extruder. I have it wired as extruder 4.

Here's the first prototype:

IMG_2104.jpg

It's based on the same design I tried for the other extruder, but here its used to directly drive the filament straight into the hotend.

And here's my first print using NinjaFlex:

IMG_2106.JPG

I printed the NinjaFlex at 240C, 40C bed and ... accidentally ... printed it at the default speed (40mm/s). But it came out rather well I thought.

I'm going to try and put one of these together in the next couple of days. Can you tell me what material you used to print it? any scaling issues or special settings I should be aware of?

Thanks for posting the On-Shape link! I pulled this into Fusion 360 and will provide a link to the files upon request.

Re: Ninjaflex and the Extruders

I've printed in both PLA and ABS (my current working version is in Rigid Ink Orange ABS which is pretty close to the Prusa orange). No scaling or special printing issues.

Re: Ninjaflex and the Extruders

I've printed in both PLA and ABS (my current working version is in Rigid Ink Orange ABS which is pretty close to the Prusa orange). No scaling or special printing issues.

Thanks, I have some Robox "Highway Orange" ABS that I thought I would use. The color is a little off but still looks good.

Robert

Re: Ninjaflex and the Extruders

I might build a new hybrid extruder which does away with them just to see.

I am absolutely interested in what you come up with, Looks promising so far 🙂

Re: Ninjaflex and the Extruders

This looks great although I struggle getting STLs from Onshape. But something I'm thinking of is, why not leave everything after the Y-Splitter in place and replace the Y-Splitter with a Plugin that has the direct extruder. The filament path after the Multiplexer is basically very confined, so even replacing the Y-Splitter with an adaptor that only has one straight filament path might work without having direct drive, could be a very flexible setup. The biggest issue will be the bottom part of the multiplexer. With my direct drive setup on the CTC I can feed in 1cm long filament pieces and it will happily shove them down the filament path one after the other. With the Prusa direct drive it was pretty uncomplicated to just push one filament in after the previous ended. With the MMU it's mostly impossible as the path is not confined enough not to have two filament strands side by side in parts and the pushing one can get onto the side of the pushed one clogging up the Splitter. This part will also hinder all flexible prints, having a non multiplexing bowden receiver that just has one filament canal might really work and would be a 30second change to switch from multicolor to flexible.

Re: Ninjaflex and the Extruders

Btw... I printed this and experimented with it. I found that with enough pressure from the feeder the print with the bowden tube is going to be perfect, the really only thing that's disturbing the flexible material is the multiplexer. So I now can quick-swap between single material flexible and multi material bowden... that is if the printer is ever coming back to live again.

Re: Ninjaflex and the Extruders

I wonder if it would be possible to tweak the design of the multiplexer so that one filament path was straight down from the top, and other three were around it - the idea being that the straight path would be good for flexible?

Re: Ninjaflex and the Extruders

Definitely possible, but will introduce the space on the bottom again where the flexible material can bulge. Once I got a solution for my PSU which died last night I'll try that.

Re: Ninjaflex and the Extruders

I'm messing around with a different mixer design with a much more constrained filament path. Very much a work in progress at the moment but I'll post about it once it does something other than jam 🙂

Re: Ninjaflex and the Extruders

I'll post about it once it does something other than jam 🙂

Any news on this?

What are the issues you discover?

I printed some of my design to do this but your design is more advanced than mine.

My main problem is printing my custom multiplexer, it need intensive post-processing (i can't manage to do it) to let the filament going through it.

Re: Ninjaflex and the Extruders

Hi Tim Happy New Years, i'm from the Bay as well, nice to meet you... do you have any updates so far? Also i remember you mentioning on Hackaday.io that you opted to for a more direct path by removing the MMU PTFE liner and installing a direct PTFE tube to the hotend... have you experience any jamming when switching back to the MMU as a result?

I asked because i remember reading a post from Peter that the re-installation of the MMU PTFE liner is quite involve... ie. unscrewing the heatbreak (by half a turn), inserting (and locking-in) the liner and then re-tighten the heatbreak... to ensure that there are no gaps between the heatbreak and the liner if that make sense. And also having to re-calibration the live-z in the process. TLDR.. Would i be better to keep the MMU liner in place?

Thanks,

Calvin

Re: Ninjaflex and the Extruders

Because I'm cooling the filament in the hotend heatsink I'm curious of the metal tubes serve any purpose in this setup. I might build a new hybrid extruder which does away with them just to see. I also have to test this with flexible filament (which was what set me on this path in the first place).

Don't bother designing it. I already did and it works better than the original so far. If melted filament was going to block the paths in the multiplexer I think you'd have problems in the original design anyway because it's still PLA where the feed paths combine. I'm reasonably sure that with the default gcode for color switching the filament cools in the heatsink above the hotend, not the feedpath in the multiplexer.

Here is a link to my redesigned multiplexer and a monoplexer I designed if you'd like to experiment with a straight feed path.

Both work and don't require any extra hardware.

Multiplexer (no metal):

https://www.thingiverse.com/thing:2740929

Monoplexer:

https://www.thingiverse.com/thing:2736405

Should fit your needs in both regards. Good luck, let me know if you need anything.

Re: Ninjaflex and the Extruders

Hey guys,

I just wanted to check regarding the NinjaFlex filament journey on MultiMaterial models. As you already might have guessed could not get the filament extruded.

I've printed and built OpenRC F1 car, and now its sitting on the table without tires 😀

Thanks,

Ruben

Re: Ninjaflex and the Extruders

@tim.w Do you have the obj files or thingiverse link for that feeder redesign you posted on page one?

Re: Ninjaflex and the Extruders

@tim.w Do you have the obj files or thingiverse link for that feeder redesign you posted on page one?

He kindly posted the Onshape links:

https://cad.onshape.com/documents/86101f4006840a222a16a165/w/d26df690bd31abbf56d497d0/e/b2f93d7a6a796380abdb084c

https://cad.onshape.com/documents/f4b156ba13bf7ea8845fc90b/w/7dce94060658fe660867de7d/e/532cbd9b73b41f3a2680bae9

I'm very interested in this project. I'd be happy to help tinker with things and try stuff out. My MMU is working fairly well on the whole, but I'm always curious to fuss with it.

Re: Ninjaflex and the Extruders

https://github.com/prusa3d/Slic3r/releases/tag/version_1.40.0-alpha1

New alpha version of slicer apparently has settings for the amount of retraction for filament change. I'd bet that solves the hybrid MMU problem.