Filament feed problem

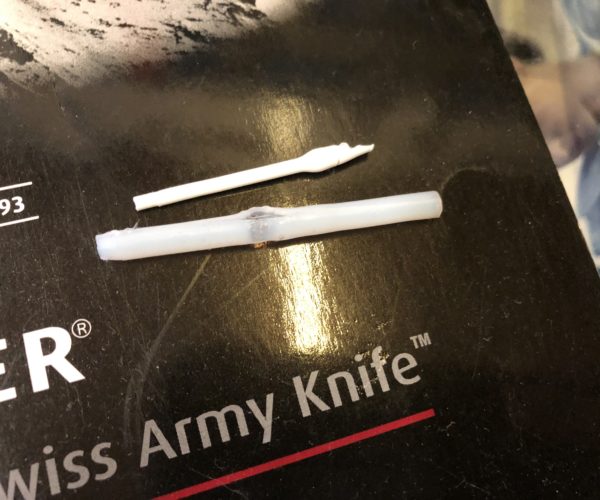

I have been having a problem with my original Prusa i3 Mk2 where the filament repeatedly gets jammed in the Teflon tube above the level of the print head. I have replaced the entire hotted assembly including the heating element, the temperature probe, the heating block itself, the nozzle several times, both metal pieces above the heating block, and gone through probably a half meter of teflon tubing. When the filament gets stuck it seems to get thicker in a specific section while some of the filament down the line is relatively normal. In the problem section the filament seems to stretch out and thin the walls of the teflon tube. I need some help to figure out what else to try.

RE: Filament feed problem

Out of curiosity, did this occur after upgrading to the new Prusa Slicer 2.1.1? I ran into a series of problems recently that I noticed after I had updated the Prusa Slicer to most current. The extruder on my MK2S was clicking, jamming/clogging when printing PTEG which previously I wasn't having a problem. I upgraded the slicer after I had a problem printing a large model that had lifted off the heat bed which created a huge spaghetti problem. It ripped off my hotend sock. After repairing that, I also noticed that the heat fan nozzle was slightly drooping, but I let that go thinking it wouldn't matter much. I decided to print a smaller model first, but before doing so I downloaded the new slicer update. I went ahead to print and that is when I was having the clogging/jamming. I first attributed it to something I did when removing all the spaghetti from the nozzle. After repeated problems with nozzle clogging, I removed the nozzle, checked out the PTFE tube to see if it was clogged -there was still some remnants of material that I removed. I put nozzle in. Same problem. I did a lot of research on line. Learned a lot about nozzle retraction, then looked at the slicer filament/printer settings and shortened the retraction length to 0.5mm. I had a successful print! I then reprinted a mod for my nozzle fan to address the nozzle drooping. Fixed that, put a new sock on the hot end I've been print PTEG through many hours with no problems. I am now go back to default settings in the Prusa slicer and see if prints using the default settings result in clogging to determine if the problem really was the slicer or was associated with problems with the way the airflow was directed from my fan nozzle.