Print bed or calibration problem

Hi!

Could someone please give me guidance on this...

Below are a couple of images of what is happening on current prints. I have been printing a lot of components, the printer has been running solidly for at least 2 weeks and there's a week to go. The material has been all PLA except one part that I did in PETG. Since the PETG part this (pictured below) has been happening at this position on the bed.

I'm concerned that I have damaged the bed because not only was the PETG part a devil to remove, some of the parts after that were flat and relatively low profile, meaning they were well adhered to the bed with little leverage to get off. As most of the print activity is in the centre there, I am worried that I have irreversible damage.

Is it possible to diagnose the issue at all, can I provide more information, has anyone else seen this? The printer is an absolutely stunning piece of kit. It was dormant for over a year, I then started this job, it's biggest yet, and I didn't need to recalibrate it, and I barely needed to even wipe the bed clean. I don't particularly mind if it is damaged because it has done so well and it will be down to my own processes that are at fault. Between prints I give it a light wipe with rubbing alcohol to remove finger grease, only if I touch the bed. If I am confident I did not touch it I do not wipe it down and it has been printing perfectly until this. Mainly, the reason for this message without my first experimenting is that I am mid print with many hours and parts ahead and I would like to find out if I need to stop the process or whether minor correction is needed.

There is a chance that it was happening before the PETG print and it is only now manifesting more obviously. I realise that I can relocate the print when I slice, perhaps that it is practice I should use systematically. Any pointers from those more experienced very welcome.

Possible causes:

- Damaged bed (delamination as a result of leverage due to strong adhesion)

- Damaged bed (surface/adhesion as a result of PETG)

- Bed distortion (due to strong leverage needed to remove some parts)

Any help greatly appreciated.

RE: Print bed or calibration problem

Hallo matthew-s20,

1th I think your bed is still o.k. When you removed your PETG-part and there were no PEI-sheet-parts hanging on it, the bed is still o.k. (Remove PETG parts only if bed is completely cooled down or you are risking a destroyed PEI-foil). To me the issue you are faced is, that on the surface you printed PETG before there is an adhesion problem. It looks like the part is warping

I don´t know what these parts are for - if it is an optical problem - stop the print and save material. If you don´t see this later, finish the print.

Then have a look @ the forum for how to reactivate / clean a building plate. If you don´t find a solution come back and post.

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: Print bed or calibration problem

I might suggest using the draft shield to help with the warping.

RE: Print bed or calibration problem

I'm printing an OpenAstroTracker.

This is the strange thing, apart from that first layer that adheres ok when the print starts, everything else is accurate. The current print is 60mm+ above the bed and it is a closed triangular shape and it is printing 100% ok at 0.1mm layer thickness.

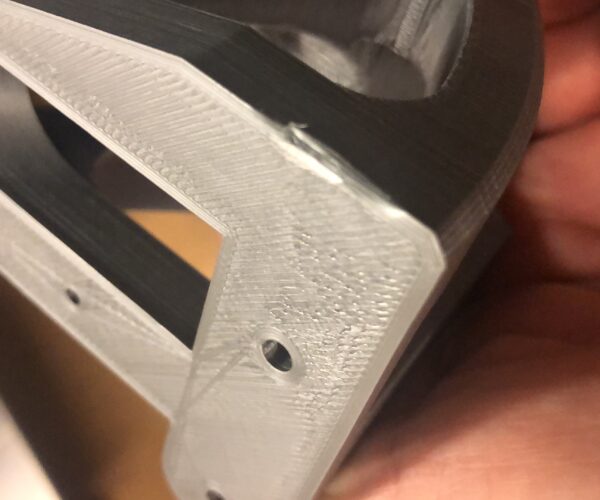

Could there be a heating issue causing contraction when the second layer starts? The first layer is fine, I believe. I'll be sure to watch it on the next print. Below is another example. This part should be round. The print completed ok, yet the part is not round at the bed. Several layers up it is round. I printed this one again and exactly the same thing happened in the same position. I realised then that a bit of filing was all that was needed to ensure roundness and the part could be salvaged. This first one was 0.3mm height hence the rough print that I regret.=

I appreciate the help, I'll take a look at the surface of the bed when the current print finishes shortly.

RE: Print bed or calibration problem

@jsw

But he is on PLA - there should be no warping.

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: Print bed or calibration problem

I've had PLA warp, but only at the corners and mostly on the textured sheet.

RE: Print bed or calibration problem

@matthew-s20

Is this "tube" in the picture still PLA - because you have a lot of stringing. Is your filament a little bit older and open for a longer period. Could it be, that it is a moisture problem of the PLA? If you have the possibility to dry it - try it.

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: Print bed or calibration problem

Read through this:

You can´t remove your PEI sheet from the printer, but you can also do these recommended things still on the printer - I know as I also have one Clone similar to the MK2S.

Forgotten: Very cool project !!!

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: Print bed or calibration problem

@clemens-m

The PLA is 2-2.5 years old but only removed from the sealed package 3 days ago. I run a very good dehumidifier in the room because it’s necessary.

RE: Print bed or calibration problem

@clemens-m

I’m very satisfied with the quality of this print. I’m really only concerned whether I have an issue to be concerned about that might be worsening. The function of the assembly isn’t going to be compromised in this case.

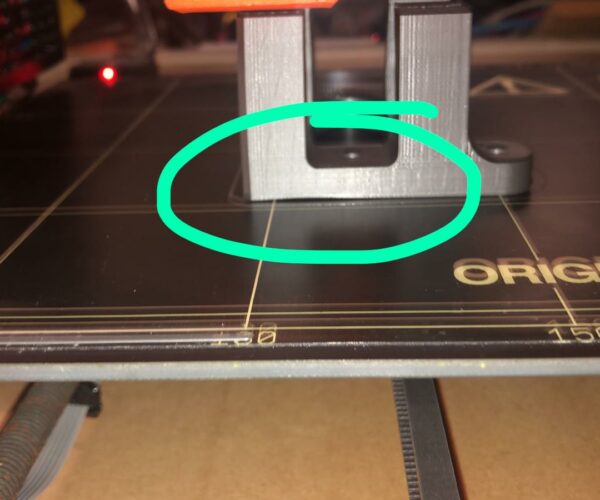

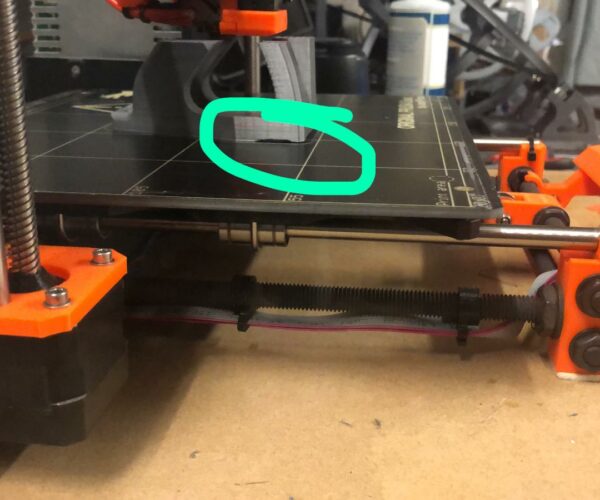

The print just finished and this is the result. I’ve circled what looks to be some unevenness on the bed. This is the third of this part I’ve printed, this one is a variant of the first two. The first two last week were perfect so something has definitely changed.

RE: Print bed or calibration problem

Next I would do is a real good cleaning - water with dish washer, cleaning with water (to get away dish washer), using very fine sanding paper (1000) and go in small circles over the complete PEI sheet (only small amount of pressure) and finish cleaning it with isopropanol alcohol. I see a lot of finger fat on the surface.

And if you really have "dents (uneven sections)" in the building plate arrange your parts on the sheet in that way, that these places ar not covered by the parts you are printing. I also have some small dents in my PEI sheet but never have problems with them. Moving parts on the PEI sheet around keeps the printing surface longer alive.

I have a telescope I inherit from my father, did some photos with it and I am thinking the whole time of a mechanism for star tracking.

Best regards, Clemens

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: Print bed or calibration problem

@clemens-m

Hi Clemens,

thanks for the time you have put into my problem. I'll try what you have suggested and give you some feedback. I have continued to print more parts and the defect is either not present or it is less severe. It could as you say be contamination of the surface and I could certainly do with optimising the bed wear. Judging by the abuse I have given this printer I am still amazed that it has been so robust and the quality of the output is not diminishing.

Matt