Issues...what next??

Background:

A friend was nice enough to donate this printer for me. Prusa i3 Mk 2s that purchased in 2017 and have upgraded to the 2.5S, .6mm nozzle, PLA 1.75 (purchased from SUNLU) . Also upgraded a few parts, like replacing all the linear bearings and drive belts with better quality parts. However the heat bed wore out and blew the fuses in the controller. He replaced the fuses and print bed, but Prusa themselves were out of the bed and so one was bought off of AliExpress. It works, but it doesn't seem to be able to get as hot so can't print ABS/ASA with it. Maybe if you replaced the bed you could get up there again. As it is, it works fine for PLA with a bed temp of about 60C.

Issues:

1. At first, had no issues printing for couple of weeks. While doing another print, filament became a mess coming from the extruder. After troubleshooting looked like the thermistor was the issue. Since the printer is 5 years old now, decided to replace the hot-end with a pre-assembled ( https://www.printedsolid.com/collections/prusa/products/e3d-12v-prusa-mk2-v6-hot-end-kit). Install went well while carefully reading instructions how to disassembly and reassembly of the hot-end. Did not remove the pre-installed 4mm nozzle since i anted to make sure the problem was solved.

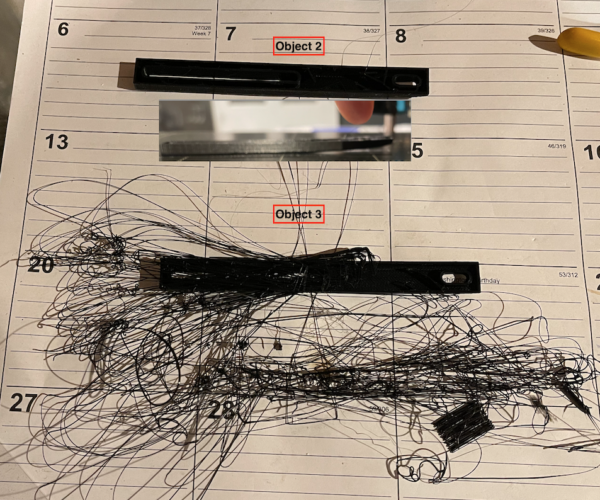

a. Looking at the first pic, i show the part which printed from a Dremmel (Object 1) printer at the campus Makerspace. While the objects (2 and 3) below it printed on the prusa. Inconsistent for sure. Object 2 - right end actually did not adhere and lifted, so not completely flat and curved up. Object 3, a mess, similar to how this all began before replacing hot-end.

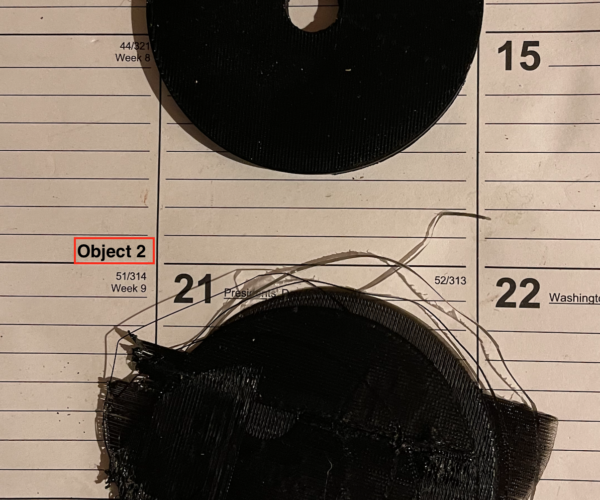

b. Another sample second pic, shows the part printed from a Dremmel (Object 1) printer at the campus Makerspace. While object 2 below it printed on the prusa. Inconsistent for sure yet again. Also, the print head actually moved from the center to the upper left quadrant of the heatbed and was in an endless loop printing the object with no filament extrusion.

WHAT AM I DEALING WITH ????

It looks like you have first layer Z calibration issues. This very long thread addresses the issue and was started in Mk2 days so contains information you will find relevant:

Cheerio,

RE: Issues...what next??

I'll check it ouit but i have done the first layer Z calibration. Maybe something i missed thankx

It looks like you have first layer Z calibration issues. This very long thread addresses the issue and was started in Mk2 days so contains information you will find relevant:

Cheerio,

RE: Issues...what next??

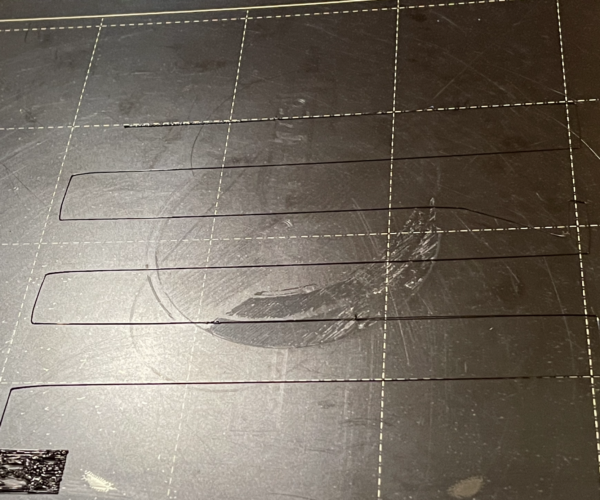

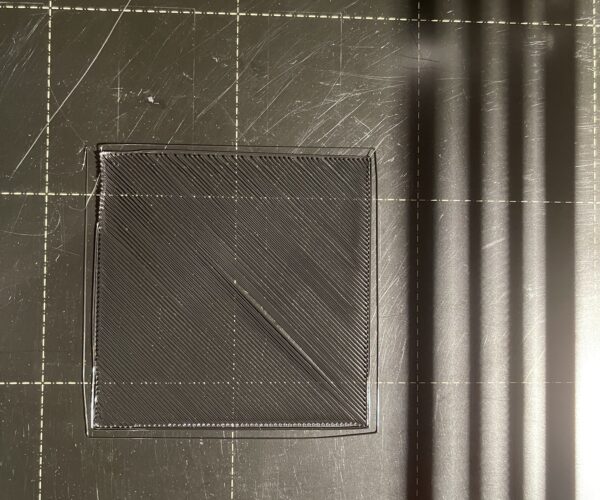

This is the result (Pic 1) i had yesterday for the first layer calibration. Not sure what I should be seeing or what is correct pattern?

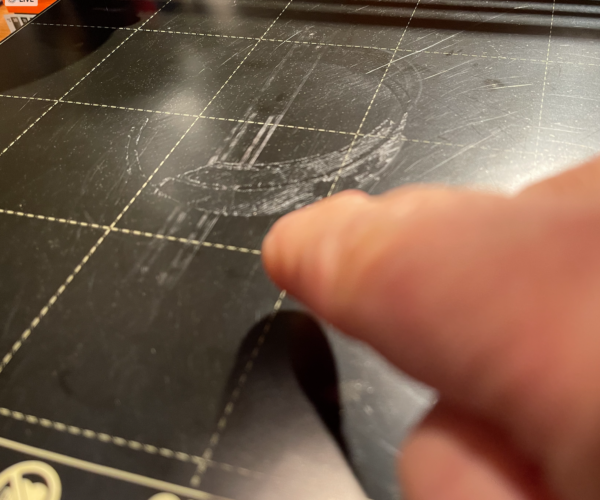

Also, pic 2 has some residue. Is this normal for this not to rub off or not an issue?

Your print sheet needs a serious clean and the Z calibration needs to go lower, follow the thread I suggested.

Cheerio,

RE: Issues...what next??

Hi yes i cleaned with 70% alcohol. I have gone through the first layer again lower. Its like -1.2. I read in manual should mot be more than -1.0?

i also rechecked the pinda height.

As far as the thread you recommended, i need to absorb the info. Too much info and howtos…

thankx for responding 👍

Your print sheet needs a serious clean and the Z calibration needs to go lower, follow the thread I suggested.

Cheerio,

RE: Issues...what next??

Is this extruder calibration method needed?

Definitely not.

See section 2.6.9 of: https://www.prusa3d.com/downloads/manual/prusa3d_manual_mk25_en.pdf

This shows the profiles you are looking for and the character of a good first layer BUT DO NOT USE the built in calibrator, you have changed the nozzle to 0.6mm instead of the default 0.4mm so you must use the procedures from the thread linked to previously and slice a first layer pattern for 0.6mm.

In that section you will also see that you are OK as far as -2

Dishwashing soap and HOT water would be better for a print sheet in the condition yours was.

Cheerio,

RE: Issues...what next??

Hey Diem,

I have the 4mm nozzle the is shipped with the pre-assembled hot-end. I wanted to make sure everything is printing correctly before changing to the 6mm.

Thankx for cleaning. I tried the 91% and still wasn't satisfied. Ue dish soap and came out much better.

still learning this stuff... 👍

RE: Issues...what next??

oh diem, question:

The printer was setup for 6mm and the Z value was at -1.81. When going to the 4mm nozzle, does that value go more negative (ie closer to bed) or positive?

There is no fixed value, it accommodates several build and useage factors and it will change slowly as the nozzle wears.

Cheerio,

RE: Issues...what next??

Hi diem, just to be clear, do not use built-in calibration but use:

Sorry for this questions. For my understanding, are there reasons why not to use MattsHub calibration procedure? I would be using the CALIBRATING EXTRUSION MULTIPLIER since i believe my extruder is bondtech?

thankx again

Definitely not.

See section 2.6.9 of: https://www.prusa3d.com/downloads/manual/prusa3d_manual_mk25_en.pdf

This shows the profiles you are looking for and the character of a good first layer BUT DO NOT USE the built in calibrator, you have changed the nozzle to 0.6mm instead of the default 0.4mm so you must use the procedures from the thread linked to previously and slice a first layer pattern for 0.6mm.

In that section you will also see that you are OK as far as -2

Dishwashing soap and HOT water would be better for a print sheet in the condition yours was.

Cheerio,

You didn't mention changing the hotend ... you might need to recalibrate if you have done so, but if you are using Prusa stock parts the work has been done for you and it's in the presets.

Cheerio,

RE: Issues...what next??

No prob... you probably missed it, mentioned in Issue 1.

thankx

You didn't mention changing the hotend ... you might need to recalibrate if you have done so, but if you are using Prusa stock parts the work has been done for you and it's in the presets.

Cheerio,

, mentioned in Issue 1.

If you mean the e3d h/e in your link then you don't need to recalibrate.

Your first layer is far too high, there is no squish at all. Go down until the extrusions merge together.

At the end of the calibration you are aiming to print a single layer *sheet*. It should be possible to peel it off in one and fold it without the threads seperating. If it breaks into lines it is too high, not squished enough. If it is a single sheet but with wavy lines or drag marks on it you are too low.

Your print sheet is in a terrible state, I would suggest replacing it - or is the other side in better condition?

Cheerio,

RE: Issues...what next??

Hey Diem,

ok I'll give it a try. Yeah I think that will be the next investment for a new sheet.

I 'm just trying to make sure this printer is still very valuable to put more money into it. I suspect it is. I'm still learning as an owner of a 3D printer.

One other question i mentioned before using either MattsHub extruder calibration (and another on youtube ). Is this procedure not used because the printer already has the preferred settings from the factory? So when the printer was upgraded to 2.5S, these settings still should not be changed?

Using Pronterface, i issued the command:

SENDING:M503

echo:Steps per unit:

echo: M92 X100.00 Y100.00 Z400.00 E141.00

I assume you are using the Mk2.5 printer profile - the values are preset in there.

If not, run the configuration wizard and scroll down on the Prusa FFF page.

Cheerio,