Part Cooling on Top Infill Layer is causing ripples.

Hi Everyone,

I'm currently running into an issue with my MK2.5S where it cooling the top infill too fast and causing it to not adhere to the lower layer (Looks like nozzle is dragging but all the layers leading up to the top infill layer are awesome and I slowed down the part cooling fan and it fixed the issue).

I can't find top infill fan speed even in the expert tab so I'm hoping someone may have run into this. Using PrusaSlicer 2.2.0 with 3.9.1 firmware. Layer height is set to 0.35 using PETG.

Any direction or help would be much appreciated!

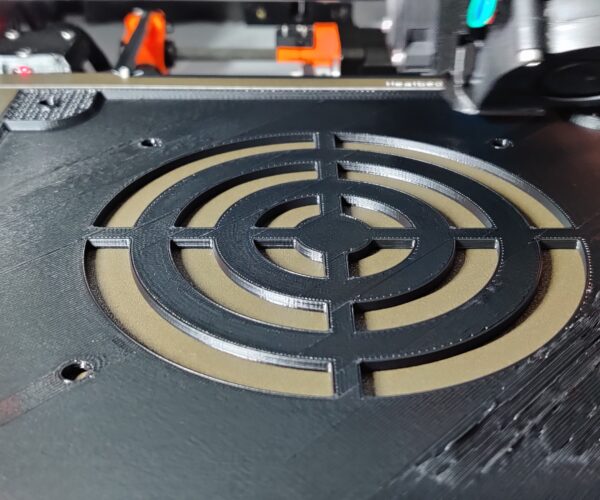

This is when I came across the issue.

This is me adjusting the part cooling speed as the layer was printing.

RE: Part Cooling on Top Infill Layer is causing ripples.

You can't yet alter fan speeds for specific print features in PrusaSlicer. You can play with minimum layer print times.

I'd start with slowing your top speed down to something like 25mm/s. Slower speeds provide more time for adhesion. Adding a top layer or two may help.

If you'd care to save your part and settings in a 3MF project file, zip it up, and attach it to a reply here, more ideas may be forthcoming.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan