Extruder Slipping Mid Print

Hi all, I have a MK2.5S that requires a silicone sock to avoid the layer 2 thermal runaway issue many have and have just got the machine printing again after an absence.

I have had issues printing with Prusament (as well as a few others) that seem to be related to Heat creep but I have not been able to solve it and would love some new ideas.

Issue: Mid print (usually following a fast infill layer) the extruder begins to click and under extrude. After a few layers the clicking becomes worse and no filament comes out. Printing with PLA with nominal Prusa settings and 0.25mm nozzle

Attempted solutions:

- Changed Filament between a dark and lighter color - mixed results not consistent

- Removed from enclosure - does not help

- Slowed Down print speed - seemed to help a little but still happens

- Reduced nozzle temperature - did not help

- Increased nozzle temperature - helped

- rebuilt hot end and re adjusted nozzle / heat block separation - helped for 1 -2 prints

- Adjusted extruder tension - helped for 1-2 prints

- Swapped Nozzles - helped for 1-2 prints

I was going to print a temperature tower but the extrusion issues occur immediate so I cannot even get to the first level. Any thoughts / insights that I should try?

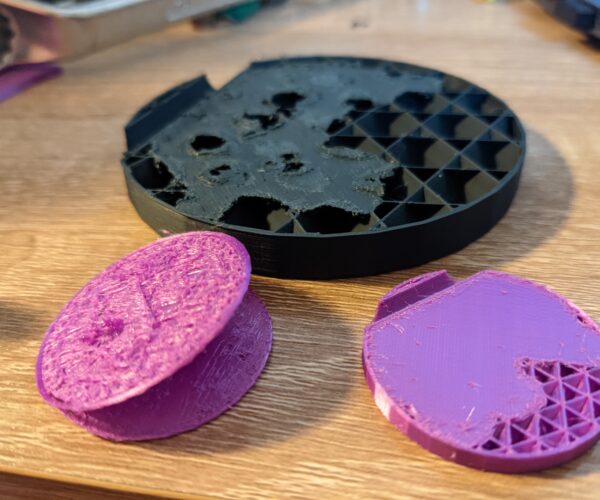

Example of Extruder skipping and under extrusion

Example of Extruder skipping and under extrusion

Best Answer by Chicago Keri:

I just did some double-checking of resistance readings on some brand new heaters for reference. Keep in mind that the resistance will vary depending on temperature. "Cold" is usually considered to be about 25C, resistance readings will rise with an increase in temperature. These heaters are often supplied with color coded leads, but there is no fixed standard. Red wires often indicates a 40w heater, Blue, a 25w heater, Yellow, 30w. For some reason, E3D uses Green on 40w "high precision" heaters and Slice Engineering uses White on their 12v /50w heaters and Black on their 24v/50w heaters..

All readings are with the full-length wires attached, as these three heaters have a connector about 100mm from the element.

a Green E3D 40w / 12v "high precision" heater: 4.1 ohms at 28C / google says 3.6ohms

a White Slice Engineering 50w / 12v heater: 3.2 ohms at 28C

a Green E3D 40w / 24v "high precision" heater: 13.6 ohms at 25C / google says 14.4ohms

It looks like you have a 25w heater! Are the wires Blue?

What I have found is that high-quality heaters from E3D or Slice seldom burn out completely. What seems to happen is that the crimps that join the heater element to the flexible leadout wires develop poor connections, which are close to the element (see picture). The heater will often continue to work at reduced power and cause all manner of troubles. It might also melt nearby wires or plastic parts.

Good Luck!

RE: A possible cause

Hi all, I have a MK2.5S that requires a silicone sock to avoid the layer 2 thermal runaway issue many have and have just got the machine printing again after an absence.

I have had issues printing with Prusament (as well as a few others) that seem to be related to Heat creep but I have not been able to solve it and would love some new ideas.

Issue: Mid print (usually following a fast infill layer) the extruder begins to click and under extrude. After a few layers the clicking becomes worse and no filament comes out. Printing with PLA with nominal Prusa settings and 0.25mm nozzle

Attempted solutions:

- Changed Filament between a dark and lighter color - mixed results not consistent

- Removed from enclosure - does not help

- Slowed Down print speed - seemed to help a little but still happens

- Reduced nozzle temperature - did not help

- Increased nozzle temperature - helped

- rebuilt hot end and re adjusted nozzle / heat block separation - helped for 1 -2 prints

- Adjusted extruder tension - helped for 1-2 prints

- Swapped Nozzles - helped for 1-2 prints

I was going to print a temperature tower but the extrusion issues occur immediate so I cannot even get to the first level. Any thoughts / insights that I should try?

I has similar issues which I eventually tracked down to a faulty heater cartridge. It can also be cause by poor connections at the MiniRambo power connections.

Might I suggest to disconnect the heater at the MiniRambo and check the resistance at the connector. It should be about 3.6 ohms.

While keeping the meter connected, try wiggling the heater wiring about an inch / 25mm from the cartridge. There should be no change in the resistance. Also, check the tightness of the setscrews on the connector and inspect the connector for signs of overheating or melting.

Good luck!

¡no entiendo Español!

Nein! Nicht Versteh!

Я немного говорю по-руÑÑки но не очень хорошо, и...

I'm not very good at English either! Maybe someday I'll find a language I'm good at?

Potential solution Found: Hot End Cartridge has too large resistance

Great Suggestion!

I checked the resistance and mine is measuring 5.9 / 6 ohms. So it would seem that my heater is not outputting the required 40W instead it is doing closer to 25W!

There is no issue with wiggling / changing impedances but the resistance is for sure higher than the 3 Ohms it should be.

I think this fits all the issues that I have been having, I will replace the part and follow up.

Thanks for the help!

RE: Corrected resistance readings

I just did some double-checking of resistance readings on some brand new heaters for reference. Keep in mind that the resistance will vary depending on temperature. "Cold" is usually considered to be about 25C, resistance readings will rise with an increase in temperature. These heaters are often supplied with color coded leads, but there is no fixed standard. Red wires often indicates a 40w heater, Blue, a 25w heater, Yellow, 30w. For some reason, E3D uses Green on 40w "high precision" heaters and Slice Engineering uses White on their 12v /50w heaters and Black on their 24v/50w heaters..

All readings are with the full-length wires attached, as these three heaters have a connector about 100mm from the element.

a Green E3D 40w / 12v "high precision" heater: 4.1 ohms at 28C / google says 3.6ohms

a White Slice Engineering 50w / 12v heater: 3.2 ohms at 28C

a Green E3D 40w / 24v "high precision" heater: 13.6 ohms at 25C / google says 14.4ohms

It looks like you have a 25w heater! Are the wires Blue?

What I have found is that high-quality heaters from E3D or Slice seldom burn out completely. What seems to happen is that the crimps that join the heater element to the flexible leadout wires develop poor connections, which are close to the element (see picture). The heater will often continue to work at reduced power and cause all manner of troubles. It might also melt nearby wires or plastic parts.

Good Luck!

¡no entiendo Español!

Nein! Nicht Versteh!

Я немного говорю по-руÑÑки но не очень хорошо, и...

I'm not very good at English either! Maybe someday I'll find a language I'm good at?

Blue wire cartridge

The wires are Blue! So that matches what your measurements show!

I must have ordered the wrong heater some time ago, I will replace with the one from Prusa 12V 40W!

Thanks for the follow up that is great info, it was not as easy to find that info online.

Confirmed Wrong Heater Cartridge

Removed the old cartridge, saw it was a 30W heater not a 40W heater, swapped it out and starting to test prints to run it through its courses again!

Fingers crossed this was the only issue, thanks again for your help!