Hot-end Nozzle adaptor:Screwing together

I’m not a fan of the nozzle adaptor. It seems that there is some play- the nozzles never get tight- and you can just twist the nozzle until it s flush with the hot-end (holder)? Really like the dedicated nozzles better- and using a whole ‘hot end’ to swap even more. I’m just worried about the nozzle getting loose, and getting wobbly or changing height or getting material gunked up in there.

Really wish Prusa would get up to speed on hardened 0.4 nozzles….

RE: Hot-end Nozzle adaptor:Screwing together

Yeah, I haven't even fired up my XL yet after assembly, but had some time to fiddle with a hotend and play with the nozzle adaptor. It just feels like an afterthought.

RE: Hot-end Nozzle adaptor:Screwing together

Nozzle adaptors are sitting in my drawer after getting the biggest blog of death I've ever had on any printer using the adaptor and a tungsten carbide nozzle. And I know how to properly swap a nozzle—have done it hundreds of times on Mk3s and Minis. This one definitely was properly seated and hot tightened at 285 degrees. I assume it was the temperature expansion differences between brass (adaptor) and TC (nozzle). Maybe one day there will be an adaptor made from nickel-coated copper, which I have in the Dragon hotends on my Mk3s and Minis. Now I use Obxidian nozzles on Mk4 and XL.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Hot-end Nozzle adaptor:Screwing together

I ordered an Obxidian to play around, don't know yet if I'll swap them all or wait what happens. Someone will do nozzles in the new format eventually.

RE: Hot-end Nozzle adaptor:Screwing together

I’ve bought them directly from E3D, or at least the brass ones. I actually went a bit crazy with complete hot ends and nozzles, and adaptors for awhile. I just don’t have a lot of .4mm hardened nozzles yet, in Nextruder form. It’s fine because I’ve been doing mainly color work in ASA, PLA and PETG, but I want to get more into functional prints, and ASA with GF so it can be colored. That is my next material of interest as a possible go-to to replace PETG.

RE: Hot-end Nozzle adaptor:Screwing together

I just got a email that the hardened E3d nozzles for the PrusaXl/MK4 are back in stock at E3D. I just picked up enough to set up my XL5.

RE: Hot-end Nozzle adaptor:Screwing together

I did my first print tonight and boy did it turn out horrible. I forgot how terrible brass nozzles are, filament sticks everywhere. Can't they at least apply some coating? Turns out Obxidian nozzles can be ordered again at Prusa, still with XL owner discount. I'll replace all of them asap.

RE:

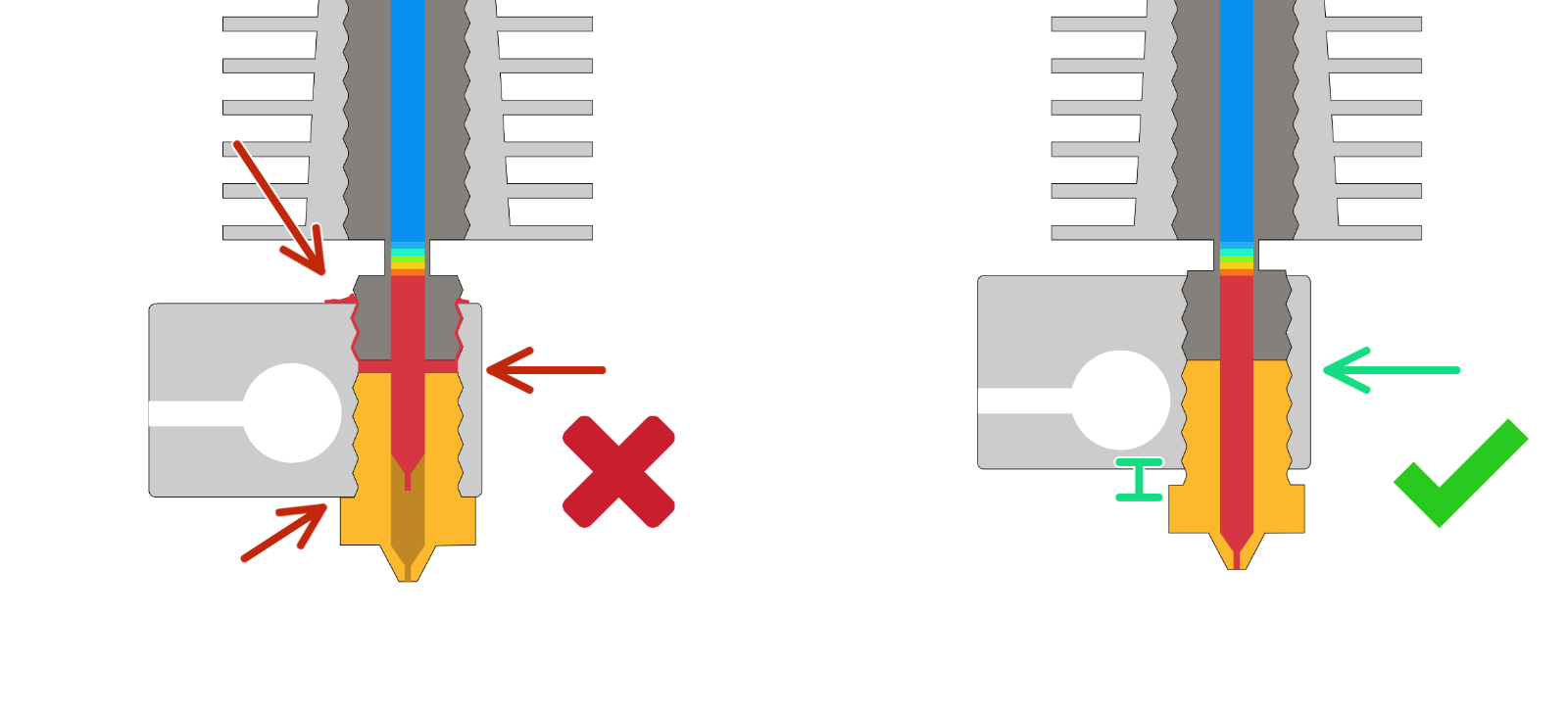

I've only used the adapter on my my MK4, It has remained tight and does leak, except out the nozzle hole, but that's a different topic. When I installed it, I inserted the nozzle into the heat block until I got the approximate gap of about 2 mm and then inserted the heat break adapter from the other side until it seated against the nozzle. After that doing the hot torqueing procedure did the the trick. I expect, just like with the standard E3D hotend, sometimes the threaded depth of the nozzle is different (short), requiring adjustment of the heartbreak insertion depth in order to the get the nozzle to properly seat. Currently I'm using a hardened aftermarket nozzle and it seems fine.

Not to be patronizing but some who read this thread may not understand proper nozzle engagement.

RE: Hot-end Nozzle adaptor:Screwing together

First chinese Nextruder nozzle was randomly suggested to me on Aliexpress:

https://www.aliexpress.com/item/1005006449158091.html

I'm not going to try it personally but maybe someone finds this interesting.

RE: Hot-end Nozzle adaptor:Screwing together

Interesting. But not sure if tungsten carbide "coated" is what I'm after. Ideally I'd buy a copper heater block and use my full-body TC nozzles. But the only Mk4 heater blocks on Aliexpress right now are aluminum. Well, while I was there I bought a couple of transparent gearbox covers, for the fun of it.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Hot-end Nozzle adaptor:Screwing together

I used Fysetc stuff in the past and it was alright. Just right now it doesn't make any sense. It's roughly the same price as the original Obxidian with the XL owner's discount in the PR shop, and that's tried and proven (tool steel with some secret coating that could also be tungsten carbide). The printer is anyway so expensive that the price of a nozzle doesn't really matter that much. But good to know that some other companies begin adapting the Nextruder.