Profiles for nozzle diamters other than .4

I was super excited to see that the new input shaper dropped today for the mk4! Less excited to see that only the .4 nozzle has a built-in profile.

I'm sure plenty of people want to try IS out with their .25 and .6 nozzles. I'm for sure going to tinker around with it this weekend and see if I can get a working .25 profile.

Let's try and pool our knowledge and see if we can decent profiles set up!

RE: Profiles for nozzle diamters other than .4

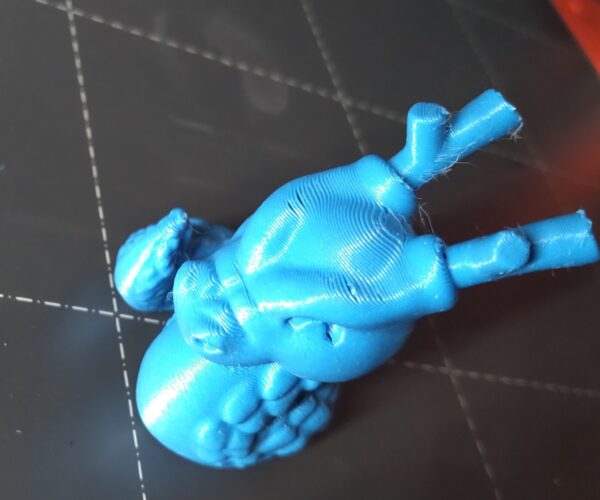

I printed a Cali Dragon with what we can call a "naive attempt" at a .25 profile. In essence just doing the bare minimum to get the print to run at the given diameter, I kept the exact same exact accels and velocity as the .4 profile.

The print finished, but not exactly flawlessly, there's some pretty significant under extrusion, I'm not sure if the nozzle can fit plastic thru itself fast enough. Still, it was LIGHTNING fast.

I'm going to do some more tweaking tomorrow, I'll probably lower the print speeds/accels by about 30% and see if it's still under-extruding, or I might try just leaving the speeds as-is and setting the max volumetric speed and work up to find the point where the top surfaces still look good.

I'll attach the 3mf if anyone wants to see what I did or branch off from my terrible settings

RE: Profiles for nozzle diamters other than .4

Might consider adjusting the max volumetric speed. I think by default the print profiles defer to the filament profiles. Which for PLA is set to something like 15mm/s. At these speeds, it will be pushing that 15mm/s pretty easily, so I might start with pushing the max flow down without changing the accelerations. The 0.15mm Speed setting for 0.25 nozzles seems to cap out just under 10mm/s naturally. A flow tower test would help figure out what the max flow is for the nozzle and settings as well.

Another possibility is bumping temps might help recover some flow.

RE: Profiles for nozzle diamters other than .4

Might consider adjusting the max volumetric speed. I think by default the print profiles defer to the filament profiles. Which for PLA is set to something like 15mm/s. At these speeds, it will be pushing that 15mm/s pretty easily, so I might start with pushing the max flow down without changing the accelerations. The 0.15mm Speed setting for 0.25 nozzles seems to cap out just under 10mm/s naturally. A flow tower test would help figure out what the max flow is for the nozzle and settings as well.

Another possibility is bumping temps might help recover some flow.

Thanks for the advice about the filament setting, I had no idea I could set the max volumetric speeds there.

I've already got the temp cranked up to 225, I might just go up to 230 if I'm still getting under extrusions after lowering the speeds

RE: Profiles for nozzle diamters other than .4

So, thru tweaking settings, i've managed to make the print complete *slower* but not necessarily, better.

I've set caps on flow rate, lowered speeds, and increased temps, but I'm still getting surface defects.

As a sanity test, I used the generic MK4 .25 slicer settings (the ones without any input shaping) and still had some under extrusions on the surface. Tomorrow, I'll slice up on 2.6.0 beta-1 and see if that gives any better results. I'll probably dig thru the start/end gcode the input shaping profiles output to see if there's anything in there that I need to change to match my settings.

But I'm like 9 cali dragons in and all of them have surface defects, it seems that the alpha was really just aimed at .4mm. I might just plug my .4mm back in and stay away from high detail models for a few weeks.

RE: Profiles for nozzle diamters other than .4

I think I may have found the culprit,

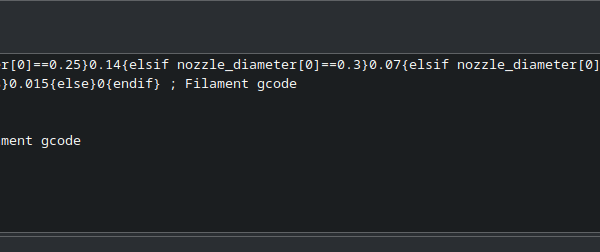

the Filament settings for input shaping contain a line of gcode:

M572 S{if nozzle_diameter[0]==0.4}0.04{else}0{endif} ; Filament gcode

if we double-check the alpha post on github we can see that M572 is the pressure advance gcode, and setting M572 to 0 disables PA, so I've been printing without it.

I'll replace it with

M572 S{if nozzle_diameter[0]==0.25}0.025{else}0{endif} ; Filament gcode

and try again. I have literally no evidence that 1/10 of the nozzle diameter is a good value to use here, but it what the previous value was, so that's a good enough starting point for me.

RE: Profiles for nozzle diamters other than .4

Unfortunate update: After messing around with the pressure advance settings, i never managed to get good quality surface layers. I tried a wide variety of values, and while I certainly succeeded in making surface quality *worse* as well as causing some pretty sever under extrusion, I never managed to get good quality results.

I've since given up and started printing functional parts with the .4 nozzle instead, which has honestly been very successful.

I'm more than happy to wait for official profiles, and just print with the old non-IS profiles in the meantime if I need to really push details.

RE: Profiles for nozzle diamters other than .4

Unfortunate update: After messing around with the pressure advance settings, i never managed to get good quality surface layers. I tried a wide variety of values, and while I certainly succeeded in making surface quality *worse* as well as causing some pretty sever under extrusion, I never managed to get good quality results.

I've since given up and started printing functional parts with the .4 nozzle instead, which has honestly been very successful.

I'm more than happy to wait for official profiles, and just print with the old non-IS profiles in the meantime if I need to really push details.

I'm waiting on my kit but was wondering if I should order a 0.6 nozzle with it. I'm going to hold off until good input shaper profiles and testing is ready. Thanks for all your testing!