ObXidian 0.6mm elephant foot

Hi,

I have tried printing with 0.6mm ObXidian nozzle using Prusament PETG 0.25 structural IS profile and it is making elephant foot. Now I wonder, if the elephant foot compensation is not set correctly in the profile or the first layer is too squished. As I'm still new to 3D printing, I lack the experience.

- FW 5.0.0-RC+11963

- Prusa Slicer 2.6.1

- Nozzle 0.6mm

- PETG

- Profile 0.25mm Structural @MK4IS 0.6

- Layer changed to 0.3 (first layer kept default at 0.2mm)

RE:

I did two more test prints, both included two boxes, where one was one layer height. The first print, with the small two boxes in the middle, looked just perfect without any elephant foot and with perfect first layer. Two hours later I tried to print the boxes positioned in the left front. Again no elephant foot is visible, but the first layer is underextruded. Probably a partial clog developed in the nozzle? It looks like the MK4 with 0.6 ObXidian nozzle is unreliable. Btw in past I tried the full bed first layer test with PETG using original 0.4mm nozzle and non-IS FW and it was perfect.

RE: ObXidian 0.6mm elephant foot

What temperature did you print at? To me, it kind of looks like it was printed too cold.

RE: ObXidian 0.6mm elephant foot

Default temperatures as provided by Profile 0.25mm Structural @MK4IS 0.6

RE: ObXidian 0.6mm elephant foot

interesting. i got the two obsidian nozzles (0,4 + 0,6 ) on Friday and printed a lot over the weekend. To me the surfaces are not as nice as with the brass nozzle.

Is it possible, that the coating reduces the diameter ?. Or that other temperatures are needed. ( steel less heat conductand as brass?)

RE: ObXidian 0.6mm elephant foot

That is for sure - the higher the volumetrical speed, the higher the effect of the lower heat conductand of the steel nozzle. Means you have to play with increased nozzle temperature.

Best regards, Clemens

interesting. i got the two obsidian nozzles (0,4 + 0,6 ) on Friday and printed a lot over the weekend. To me the surfaces are not as nice as with the brass nozzle.

Is it possible, that the coating reduces the diameter ?. Or that other temperatures are needed. ( steel less heat conductand as brass?)

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: ObXidian 0.6mm elephant foot

interesting. i got the two obsidian nozzles (0,4 + 0,6 ) on Friday and printed a lot over the weekend. To me the surfaces are not as nice as with the brass nozzle.

Is it possible, that the coating reduces the diameter ?. Or that other temperatures are needed. ( steel less heat conductand as brass?)

That's interesting. With what filament?

Normally, when the temperature is too low, the filament starts to be matte. I have not seen such effect with ObXidian nozzle.

Anyway the ObXidian nozzles are slightly higher than the original one. This could also affect the temperature on the tip, because more part of the nozzle is exposed to the air form cooling fan.

RE:

interesting. i got the two obsidian nozzles (0,4 + 0,6 ) on Friday and printed a lot over the weekend. To me the surfaces are not as nice as with the brass nozzle.

Is it possible, that the coating reduces the diameter ?. Or that other temperatures are needed. ( steel less heat conductand as brass?)

E3D claims the obxidian nozzles don't require additional temperature over regular brass nozzles, as the nozzle is still mostly made of brass. So that shouldn't be the problem. I don't have one myself, so I can't say from experience if that is actually the case or not.

RE:

I had an issue where I was suddenly getting elephant foot and it turned out that some how my z height had changed and my nozzle was wayyyyyy to low. I had to raise by about 150.

That said your image of your first layer looks wayyyy to high as it looks like there are gaps between the filament runs.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: ObXidian 0.6mm elephant foot

..........wayyy to high....

@ John, shouldn't the auto-calibration of the MK4 take care of that ?? ( it would only make sense to me if the nozzle is loose)

RE: ObXidian 0.6mm elephant foot

to be honest I didn't think what printer it was o, but I don't know much about the MK4 - but something does look wrong

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: ObXidian 0.6mm elephant foot

..........wayyy to high....

@ John, shouldn't the auto-calibration of the MK4 take care of that ?? ( it would only make sense to me if the nozzle is loose)

This could be one of the possible reason. When I swapped nozzles, I noticed I could unscrew the nozzle by hand. This can also affect the heat transfer. Now I take more care when I tighten the hotend assembly into the nextruder to make sure not to rotate the assembly when it is already tightened in the nextruder.

RE: ObXidian 0.6mm elephant foot

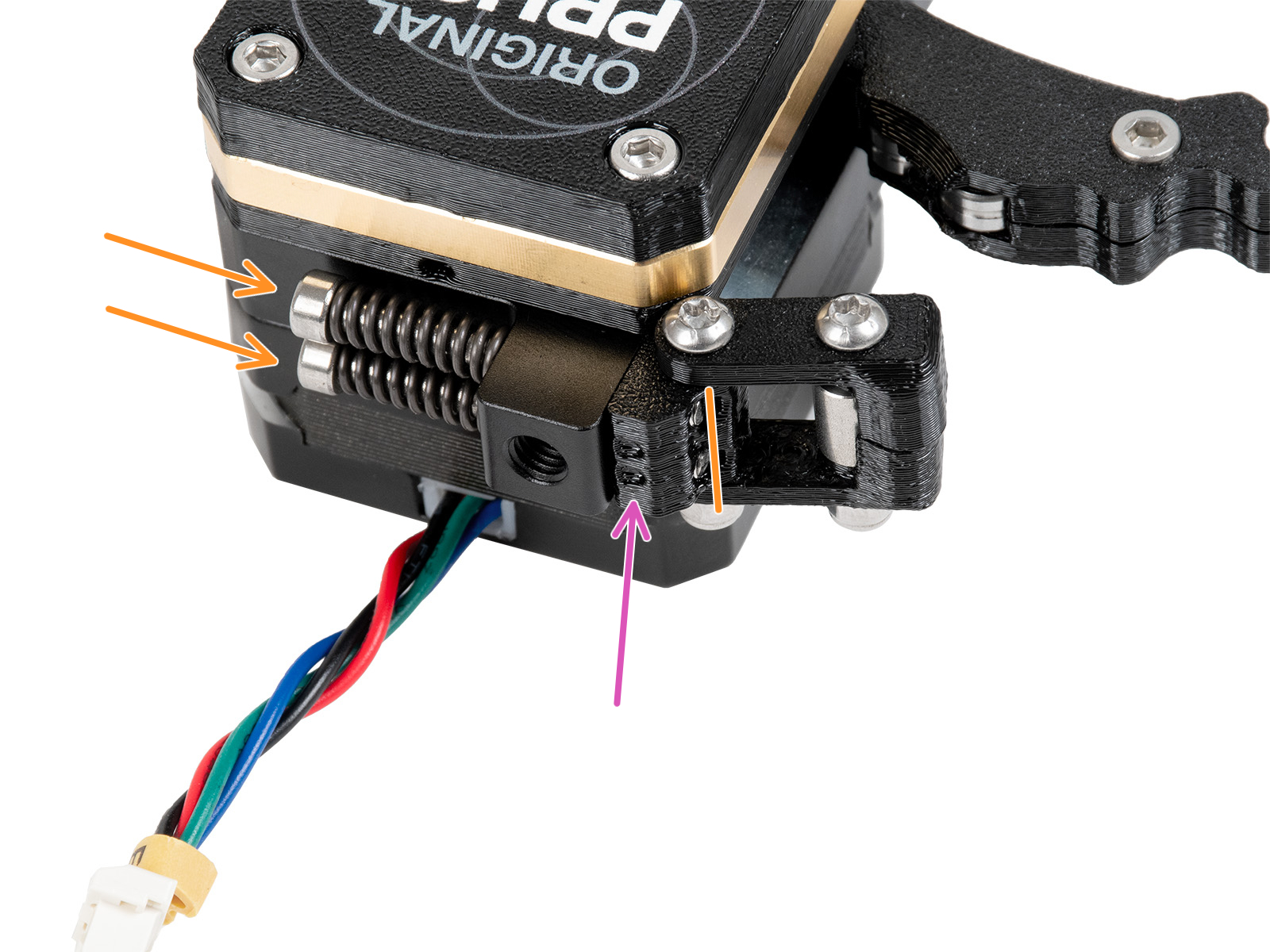

How much did you screw in the idler screws? (the screws with springs)

You MIGHT have them too tight and the filament can't feed enough, or they might be too loose and it's slipping.

You could also check and make sure the idler-swivel spins freely. If it was tightened together too tight it might not spin properly. The pink arrow.

Did you try printing in PLA to see if it has the same results?

Did you try printing in PLA to see if it has the same results?