First self-sliced model...damaged print bed, maybe damage to nozzle?

Well, if you run beta 4 PS, alpha IS, and beta PrusaLink you have to expect issues, right?? So first prints and impressions.

1) Very excited about what this will end up being. Printed benchy (27min) and bonkersbenchy (12 min) and wow. Great quality for such speeds. Very exciting.

2) Sliced a model we regularly make on MMU unit. Did with two manual color swaps. What is normally a 3hr 33min print turned into a 1hr 36min print. Add 10 minutes for purge tower if were using MMU and still amazing speeds. Quality was very good except for one major issue. I've attached pictures. A couple layers appeared to not have the correct increase in Z height. I could hear it crashing across the grid infill. Looks-wise it appears very similar to the bulge issues that occur sometimes when there is a solid infill shelf, but there is only the tiniest amount of solid infill here. The total piece measures a height of 31.6mm when it should be 32mm. Running 0.25 layer heights at this level which would seem to support 2 layers not printing at right z height. Also one of the tiny solid infill corners did not print (the other was fine). Attached pic of that too. Textured sheet. First layer was fabulous. Some detail like our debossed company name actually turned out BETTER than on a normal MK3S+ print at way lower speeds. Pressure advance at work I'm guessing.

3) To try and see if problem persisted I sliced another smaller model (this one on beta 4, the previous on beta 3). But when I tried to print this the preprint routine took 6 minutes. At each Sensor point it would try and then do a little spiral around it. When the print started it dug the purge line into the sheet and then started the print doing the same thing before I could stop it. This damaged the sheet for use on cosmetic pieces as the lines will show up on the print. This was with a textured sheet. I had pre-heated the unit in order to clean the nozzle which I did in my normal way of metal tweezers. Not sure if this had any impact.

Did reset and then turned off and back on. Cleaned sheet best I could to verify the damage. Deleted gcode (which had transferred from PrusaLink, with issues) and then just copied to the USB. Ran print from cold start. The pre-print routine was way faster, like it was for benchies and previous completed print, so thought all was well. BUT then it dug the purge line in and dug in the start of the print again. Was watching as it dug in and it seemed to pull the whole nozzle sideways and seemed to twist although that seems unlikely. Not sure if it damaged the nozzle. Definitely did more damage to the sheet.

Now at a loss as to what to try. I guess uninstall all the beta stuff are revert to stock and see if it will work. If not then will have to contact support.

Still excited but definitely disappointed at the immediate problems.

Side note: met Josef and his group at the Seattle PUG Meetup which was very cool.

Best Answer by carlmmii:

Have you checked if the nozzle thumbscrews came loose? If they aren't holding the nozzle tight, it could be shifting the vertical position of the nozzle during the filament change.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

Pre-sliced Spatula is having the same problem. Nozzle is pushing hard into the build plate. Is the nozzle supposed to twist as part of the load cell process? Can't imagine it is.

I had re-run self-test before this print and it all checked out OK but obviously load cell is not working correctly. Wanted to try pre-sliced before reverting the FW. Given I had good first layers on pre-sliced and my own sliced model, I am thinking something else has gone wrong hardware wise.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

Have you checked if the nozzle thumbscrews came loose? If they aren't holding the nozzle tight, it could be shifting the vertical position of the nozzle during the filament change.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

I do wonder if these load cells operate reliability over time.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

@carlmmii

Thank you for the idea. I talked to support and they suggested I look at that as well and also from a pic they had me send that the nozzle might be too low. I'll be checking that today and see if it helps. I'll post if it does.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

This is exactly what I am wondering about...the minute these fail, there was be catostrophic results and damage to print beds and maybe even the extruder assembly.

I do wonder if these load cells operate reliability over time.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

very curious what you find, even if the nozzle is slightly off , the load cell should be able to account for that , at least that is what I thought.

@carlmmii

Thank you for the idea. I talked to support and they suggested I look at that as well and also from a pic they had me send that the nozzle might be too low. I'll be checking that today and see if it helps. I'll post if it does.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

UPDATE:

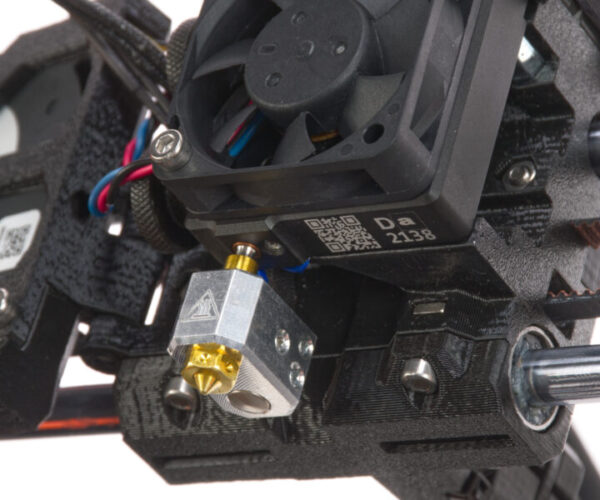

Per the recommendation of Prusa support and @carlmmii I checked the thumbscrews and that appears to have been 100% of the problem. The screws were completely loose and I could push the nozzle up with a finger. Support looked at a photo of our setup and referred me to the nozzle swapping procedure which has a photo showing how far up the throat the nozzle should be. I currently have it pushed up even a little further, basically as far as it will go.

Not sure if the Input Shaper speeds made it loosen or it was just loose from the factory. The thumbscrews do not have a satisfying feeling when tightening. You can't really feel them "cinch" in. But I just tightened them as much as I could and hopefully they stay good.

I did another self-sliced print of a smaller but similar object as the one in the above pics. The bad section in the first print (the bulge in the pics) I believe was from the moment the thumbscrews released Result was just a couple layers where the nozzle was too close.

I'll attach pics of the new print below.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

Here are a couple of pics of the self-sliced object printed after tightening the thumbscrews. Results are fantastic. Our normal print takes 1hr 48min on a MK3S+ MMU2 optimized for speed. This print took 48min using stock speeds for input shaper. Even accounting for the 2 quicker manual filament swaps that is an impressive result. Quality is really really good. Honestly it is better than the MK3S+ results which are just fine themselves. I took a pic of the back where our brand is debossed, though not sure how visible it is, and this section is considerable better than with our MK3S+ settings. We paint seam blockers on the front and most of the seams start on back corners where they aren't great with the MK3. I'm sure we could fix them in the MK3 but have bigger issues. Much improved on the MK4 IS however.

Thanks to @carlmmii and Prusa Chat Support. Fingers crossed that thumbscrews stay tight.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

Here is the pic Prusa support referred me to. If you have this problem make sure the nozzle throat is at least as far up into the body of the extruder. The copper colored part on my current setup is even a little further up than this but is close.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

that is great information! thank you for sharing that. I just checked mine after, have 10 hours of use , 5 of which are with the Input Shaper firmware and they are still very tight.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

Good to know. Yeah, I really hope they were just loose from factory and that they will now stay put. I didn't really look at the thumbscrews but figuring if they don't stay tight I will put in a spring washer or something to try and solve. Hopefully won't need to.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

Glad it was as simple as that! Also a nice reminder to check the tightness every once in a while considering the extra vibration we're working with now.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

Considering how little pressure it takes to trigger a useful reading on the load cell, hopefully they can (or are) using the "stall guard" that the MK3s has (based on motor voltage?) to detect unreasonable force when leveling...

This is exactly what I am wondering about...the minute these fail, there was be catostrophic results and damage to print beds and maybe even the extruder assembly.

I do wonder if these load cells operate reliability over time.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

I just checked my factory assembled mk4, and while the thumbscrews were still tight (ive only made a few parts on it with no real problems, although I swear I heard it dragging across some infill a few times), the hotend is sticking out substantially farther than their provided image.. Should I loosen it and just push it back up, and if so, what recalibration procedure should be done to ensure success? Might be wise for everyone to check this, thanks for this initial post!

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

No recalibration necessary. Just loosen both thumbscrews to the left of the nozzle, push the hotend assembly up as far as it will go (there's a hard stop), make sure it's aligned like shown in the picture above, and tighten both thumbscrews again.

Dragging across infill is not immediately a sign of the nozzle height dropping. Depending on the filament and part geometry, your part could just be warping and lifting itself up. If this is unavoidable (or a regular occurrence), you might want to increase your z-hop height.

RE: First self-sliced model...damaged print bed, maybe damage to nozzle?

Dragging across infill is how I first noticed the problem. But it was obvious that it was dragging...really loud. For the photo I attached that was from Prusa support the little copper colored band at the top is what they were referring to. Mine was quite a bit further out but then it was loose. I pushed it up as far as I could with a thumb on the nozzle and fingers on top of pancake motor and then tightened the thumbscrews as tight as I could.

No recalibration needed, it just works (as advertised) though I did run the full self-test. So far still working for me.