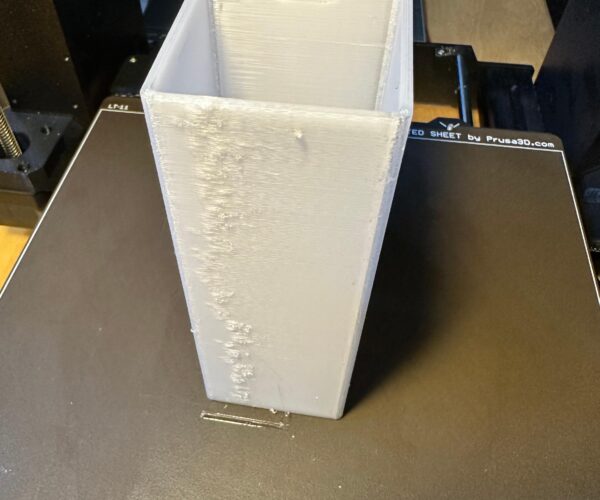

Artifacts on PETG printed part

I flashed my MK4 with 5.0.0-alpha1, printed the bundled GCODEs (bonkers benchy, 27 minute benchy), no problem. Then sliced and printed some parts (3d printer test, articulated flexi animals) in PLA, PETG and PETG-CF, also no problems.

Tried to print this relatively simple part in PETG and consistently getting artifacts on Y sides. Re-dried the filament and also tried different roll of filament - same artifacts.

- Sliced on standard IS settings on beta3 of the slicer.

- Filament is Overture transparent PETG.

- Nozzle is 0.4mm Diamondhead with Nextruder V6 adapter.

Uneducated guess: Looks like a potential problem with pressure advance .

I can share the design and/or GCODE if needed for the repro.

RE: Artifacts on PETG printed part

My guess is that the filament you used does not match one of the included IS profiles. You will have to experiment a bit and change the value for pressure advance, in the custom g-code of the profile for the filament (M572 ....).

So far I have just tried filaments that have profiles with @MK4IS in the name, PLA, PLA Blend and PETG. No artifacts like in your photo.

RE: Artifacts on PETG printed part

I would be putting focus on the diamondhead nozzle. From my experience with it (both the 0.4mm and 0.6mm), they both ooze like crazy, so throwing them into the mix at 3x normal speed is going to either hide or exacerbate their quirks.

Where is the seam position in relation to the blobbing on the wall? I'm wondering if those blobs are actually leftover ooze from the travel/unretract move.

Something else I've noticed with the diamondhead is that it has *very* low effective thermal mass, since it's wicking directly to the filament essentially. Which means temperature control is extremely dependent on volumetric flow rate. I'd be curious to see if the corner sections have a much lower flow rate -- the rapid acceleration the hotend can make in the X-axis would definitely make it more apparent where you're seeing it.

From my own short testing with the diamondhead, it's just resulting in uncontrollable stringing, akin to my experience months back when I tried using it with my mini (specifically on PETG/CPE -- no idea with PLA, it's too well behaved for me to draw any conclusions). Also have to crank temperature by 20-30c as well just so it can keep the proper actual filament temperature.... but I don't know yet if that's universal to all nozzles.

RE:

I have the same setup as OP (Diamondback .4 + Adaptor + using IS alpha) and I also have major issues with PETG.

Solid layers (1st layer) lays down fine, but the minute it starts on infill (ie 15%, 20% exc) it turns into a mess.

I have tried different temperatures with no success.

PLA works wonderfully, its just the PETG that is doing it.

I have tried both PRUSAMENT PETG and GENERIC PETG profiles.

The only thing that seems to solve it, is slowing it wayyyyy down to like 25-50 mm/s

RE: Artifacts on PETG printed part

This looks like exactly the mess my black PETG was producing. Basically full of water. Ensure to dry at least at 55° for 8 hours at least.

Then the results would change completely. I switched from "unusable" to "good". 😉

RE: Artifacts on PETG printed part

Tried the same model again 5.1.0-beta firmware and 2.7.0-rc1 slicer and artifacts are gone. Unfortunately I didn't retain the original G-code to check whether slicer or firmware fixed it.

RE: Artifacts on PETG printed part

Interesting, thanks for following up on this since I'm dealing with the exact same issue on 5.0.0 and slicer 2.6.1 - my PETG seams are really inconsistent with my 0.6mm nozzle (most of them seem either under or over extruded) and it seems like the same settings for different parts have wildly different results. I will update everything and give it another try. I'm using Zyltech PETG, FWIW.