Wood PLA first layer problems

Is anyone else having problems printing wood PLA?

Been printing great with regular PLA (on the smooth sheet) and PETG (on the textured sheet). Specifically, I'm printing Colorfabb Woodfill (sold by Prusa) on the Mini. 0.6mm hardened steel E3D nozzle. Using the built-in printer profile and ColorFabb woodFill filament profile in PrusaSlicer, tried 0.2 and 0.3mm layer height (I read that thicker layers were better for wood).

For the life of me I can't get the first layer to adhere well to the smooth sheet. Anyone else having this problem?

My sheet is well-used at this point, and I have a new one on order. Fingers crossed that this solves it, but wanted to see if there are any other tweaks I could try.

TIA.

RE: Wood PLA first layer problems

I don't have any problems with my Filamentive wood filaments. Same build plate preparation as with PLA.

On the Mini I would recommend reducing the fan speed to 80%. That fan duct is a horrible design.

RE: Wood PLA first layer problems

On the Mini I would recommend reducing the fan speed to 80%. That fan duct is a horrible design.

80% specifically for wood? Noticed that in PrusaSlicer it's disabled on the first layer anyway, so probably not the problem for me...

Edit: Also, what's intuition behind the "horrible" comment?

RE: Wood PLA first layer problems

@syd

For all PLAs.

RE: Wood PLA first layer problems

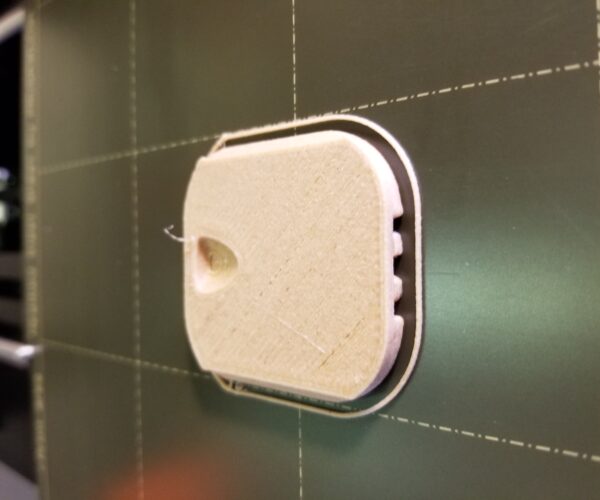

Update 2: Based on the observation that the filament was very brittle and nearly impossible to unload cleanly, I thought maybe there is too much friction in the feed process. So, I upped the flow speed by 11% and slowed the movement speed values to 30-40% of the default in the slicer. It got better, but still having intractable co-adhesion problems.

RE: Wood PLA first layer problems

Update 3: To sanity-check, tried printing the new roll of ColorFabb Corkfill that just arrived, using the default Corkfill profile in PrusaSlicer (which looks the same as the Woodfill profile). Printed perfectly!

Wondering if I just got a bad spool of Woodfill?

RE: Wood PLA first layer problems

Update 4: Solution found!

After several hours of trial and error, decided to play with heat settings, which seemed to help. Ended up switching back to a 0.6mm brass E3D nozzle, and it printed perfectly with the default settings. Note that this was not necessary for the Corkfill (printed fine with hardened steel).

This is the first instance I've seen of heat effects from nozzle types not just causing issues, but 100% failure vs 100% (okay, 99%) success. Thinking this means I should try dialing in the temps on the steel nozzle next...

RE: Wood PLA first layer problems

[...] This is the first instance I've seen of heat effects from nozzle types not just causing issues, but 100% failure vs 100% (okay, 99%) success. Thinking this means I should try dialing in the temps on the steel nozzle next...

A PID tune with the new nozzle fitted might be a good idea as well. In general, you probably want to slow down and bump temps slightly for filled filaments and a hardened nozzle.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…