RE: What causes these problems? Bad Cooling?

Are you a beginner in 3D printing or a veteran? My answer is geared towards a beginner...so if you're a veteran, might not be helpful.

I've never had any kind of inadequate heating or cooling issues on my Mini+. You bought it used you say? Have you done all/any maintenance you could do first (i.e. get a new nozzle, make sure the tension is right on the belts, check tension screw on the extruder gear housing where filament feeds in, make sure XYZ is level and straight, make sure the gear teeth are in good shape and not clogged with old filament flakes, etc.) Like buying a used car, there could be all kinds of mistreatment and lack of attention that went into the printer.

*ASSUMING ALL THAT IS IN GOOD SHAPE* To me it looks like ultra-crappy and/or wet filament that is 'goopy' and doesn't cope well with short/fast movements and retractions. Also generally speaking the lines all around the 'normal looking' parts of the print are nasty and rough like there is under/over extrusion issues all during the print (again, super crappy filament or maybe an issue regarding the above maintenance items).

So my short answer is make sure the maintenance items are done and beautiful, make sure the filament isn't old/wet/bargain barrel...and the Mini+ should give you years of great service.

https://help.prusa3d.com/en/article/regular-maintenance-mini_133222

Lubricating the smooth rods might help and your belt tensions may need adjustment.

Cheerio,

RE:

Thanks for the replies.

I'm more an beginner than a veteran.

Maybe I have to reassemble parts of the printer and especially check the bearings.

I'll also do a Factory-reset of the printer afterwards and re-calibrate it (e.g. Steps per unit)

The previous owner installed a BodTech-extruder and -heatbrake. He also did the "Silicone Mod".

The thought of disassembling the printer and reassembling it makes me a bit nervous, because I don't want to break it.

Edit: The stats of the Printer:

X: 9.4 km

Y: 9.2 km

Z: 44.0 m

Filament: 438 m

Time: 5 d 0h

RE: What causes these problems? Bad Cooling?

Here is what I did so far:

- Lubricated the bearings and the rods

- Cleaned the extruder

- Reset the printer to factory-settings

- Altered the settings for the Z-Axis length to 192, Extrusion steps to 415 and inverted the extrusion direction

- Reverted from Silicone-Mod back to stock bed

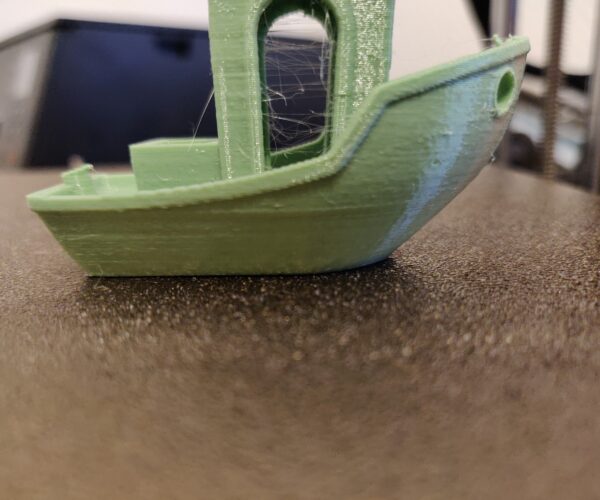

After printing a test Benchy I'm not sure if the quality is better now.

As Filament I'm using "Prusament PETG Pistachio Green". I already dried it a weak ago because Printing sounded like making popcorn.

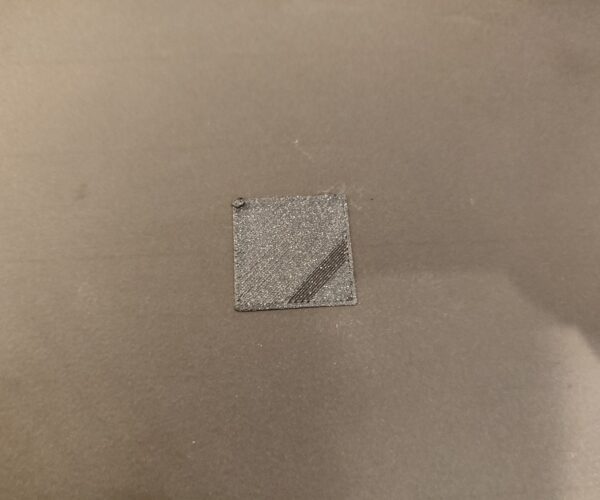

I'm curious what is causing these gaps between the extrusion-lines (last picture)

RE: What causes these problems? Bad Cooling?

I found petg pistachio green much harder to print and created for it separated profile, adjust flow rate by +1 or +2 and cooling by 20% also direction of print is important. Benchi, picture 3 is cooling issue.

Try with orange or black/galaxy black if faced issue then its printer problem.

For threading change from 3.2mm to 3.4.

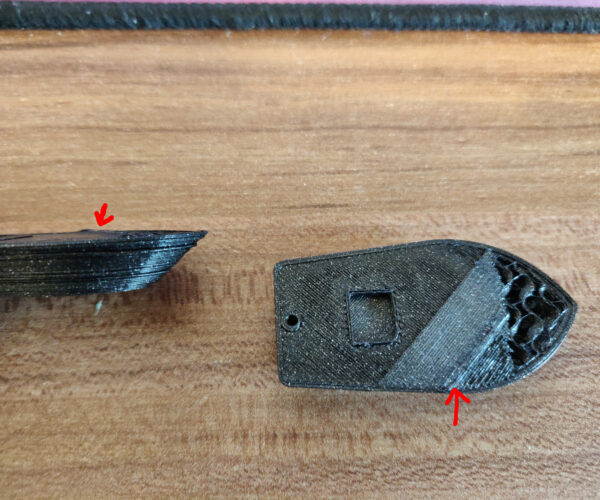

Post 1 pic 3 looks like looks like problem with xyz axis problem I suspect nozzle hit print.

mini+ [bondtech dual drive, revo, reprinted with PA11-CF and ASA] lives in photo tent.

mk4 upgraded to S with mmu3 and gpio (with some parts reprinted) lives in prusa enclosure.

Voron 0 ldo kit with dragon burner and…

RE: What causes these problems? Bad Cooling?

* extrusion multiplayer +0.1 or +0.2

mini+ [bondtech dual drive, revo, reprinted with PA11-CF and ASA] lives in photo tent.

mk4 upgraded to S with mmu3 and gpio (with some parts reprinted) lives in prusa enclosure.

Voron 0 ldo kit with dragon burner and…

RE: What causes these problems? Bad Cooling?

Thanks for the Response 🙂

Today I got the package with other filament and I tested the Benchy again. I had to stop the print...

Since then I started to calibrate the printer again with "PLA Prusa Galaxy Black".

I set the extruder eSteps to really extrude 100mm filament if 100mm is requested.

Currently I'm calibrating the first layer and I'm really frustrated.

What could be causing this problem? The side with the "underextrusion" has 0.14mm, the other side has 0.24mm.

If the bed isn't level, shouldn't the printer automatically compensate?

RE: What causes these problems? Bad Cooling?

try checking stuff according to this video

mini+ [bondtech dual drive, revo, reprinted with PA11-CF and ASA] lives in photo tent.

mk4 upgraded to S with mmu3 and gpio (with some parts reprinted) lives in prusa enclosure.

Voron 0 ldo kit with dragon burner and…

RE: What causes these problems? Bad Cooling?

Not really related to your problem. But I noticed that your filament have more moist in it. You probably notice a loose strings (as for example on your boat picture, you can see strings in cabin). It is caused by moist in filament. Filament needs to be dry to print.

As for your issue, it seems like either belt or rod bearings. If I'm dealing with your issue, I would take apart - take bearings out and re-lube and put in proper way as assembly manual shown ( https://help.prusa3d.com/guide/3-x-axis-extruder-assembly_199519 starting Step 6). That what I would do.

RE: What causes these problems? Bad Cooling?

Thanks for the replies again.

@str0gg I'll check that.

@jmh714 I already re-lubed the bearings. Since this a used printer, is it possible that the bearings are broken? How can I check that?

While still using PTEG Pistachio Green I did a test-print with the original extruder and the Bontech extruder and the Bontech' one resulted in a bit better quality, but not much.

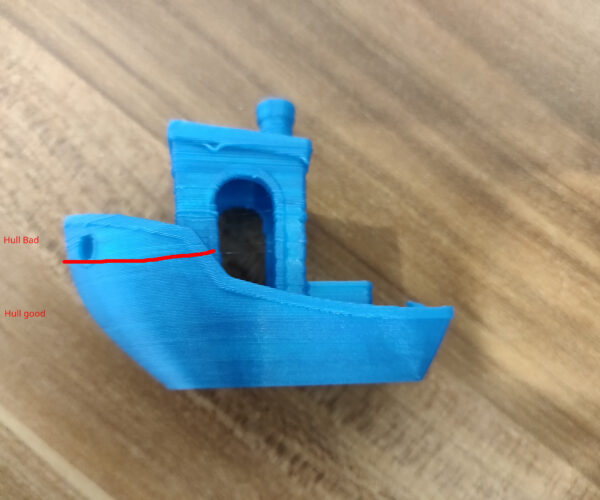

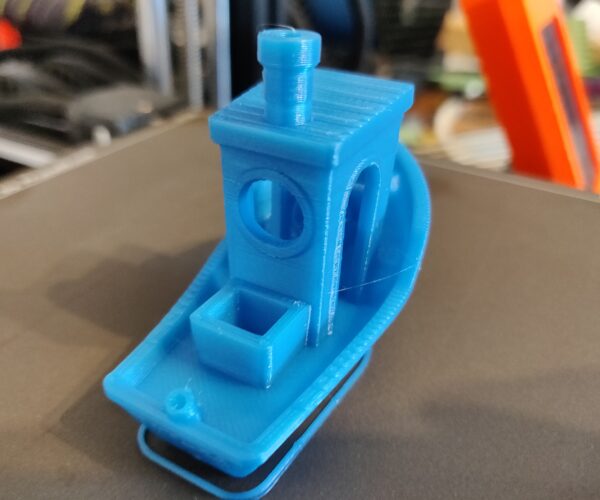

Since my care-package from Prusa arrived I also checked PLA-Prints. The Galaxy-Black was a whole disaster, where I had to stop the print since the nozzle kept bumping into a warped piece of the Benchy... Then I tried the Azure Blue which printed a Benchy, but in not so good quality. After drying the filament (Azure Blue) the hull was printed better, but the rest not so much...

I also replaced the PTFE-Tube from the extruder to the hotend and the PTFE-Tube inside the hotend.

The Benchy was sliced with the defaults of "Prusament PLA".

What are some tests I can do next to pinpoint the actual problem with the print quality?

Here are the failed Galaxy-Black prints:

Here is a comparison between the "Out of Box" Print, "first dry" and "second dry":

Here is the last print (the right most one) in more detail:

It's hard to judge from the pictures but easy to do with the print in your hand: Have you now got rid of your X-Y assymmetry?

Find a flawed layer and follow it round the model - does it (for example) remain 'out' all the way around? - or 'in', or piched or goopy?

Or does the 'out' on one side correspond to an 'in' on the other side?

Cheerio,

RE: What causes these problems? Bad Cooling?

I'm currently on vacation, so I cannot test anything right now.

Before I tested the Angle between the XY-Axis, and it was a bit of (around 0.5mm). The X Axis is a bit off to (<1mm). That's why I'm planning to redo the silicone-mod.

The layers on the Benchy are very good on the lower part of the hull. One layer in this Area started a bit 'out' on the back, but moved back in line towards the front.

As far as I can tell the Layers are either all 'out' or all 'in'. The studs of the cabin appear to be wabbling in X and Y direction.

On the chimney I can definitely see one layer beeing all the way around being 'out'.

I hope you can do something with my 'analysis'. Maybe I can find someone in my are to take a look at it.

Thanks 🙏

RE: What causes these problems? Bad Cooling?

I think this is not caused by the X/Y axis, something might be wrong with the extruder. I would suggest to de- assemble the extruder and check against any anomalies.

I hope you can do something with my 'analysis'. Maybe I can find someone in my are to take a look at it.

Your underlying problem is this is a second user machine and the previous user obviously tinkered with it ... the various mods often cause more issues than they fix. The closer you can get to a stock configuration the more likely you are to get useful help.

Take a look at: https://world.prusa3d.com/

You may be able to find an active user n your locality who could give you hands-on help.

Cheerio,

RE: What causes these problems? Bad Cooling?

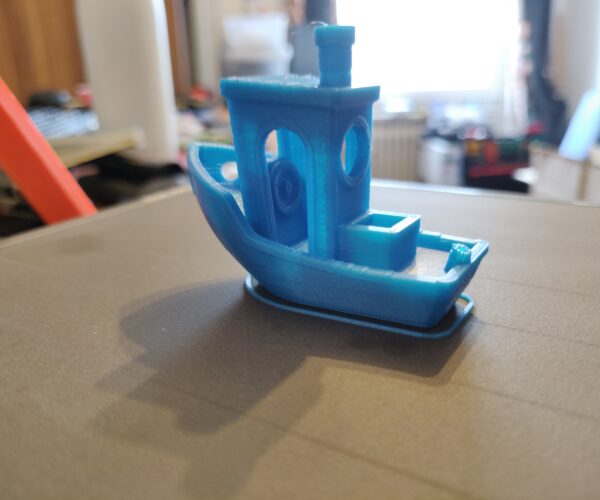

I was successful, at least about 90% 😉

My plan was to change the heatbreak, since I had some spare ones (also Bondtech), but I couldn't screw it out of the heatblock.

Luckily I also had a spare heatblock, so I changed both.

While assembling the printer back together I discovered, that there was thermal paste in the threading of the "old" heatbreak.

I also measured the "old" PTFE-tube again, and it was a bit short (35.8mm). So I decided to cut a new one, which is slightly to long (36.1mm).

The result is a non-perfect (some lines on the cabin and the chimney is not perfect) Benchy, but it's in a whole other league:

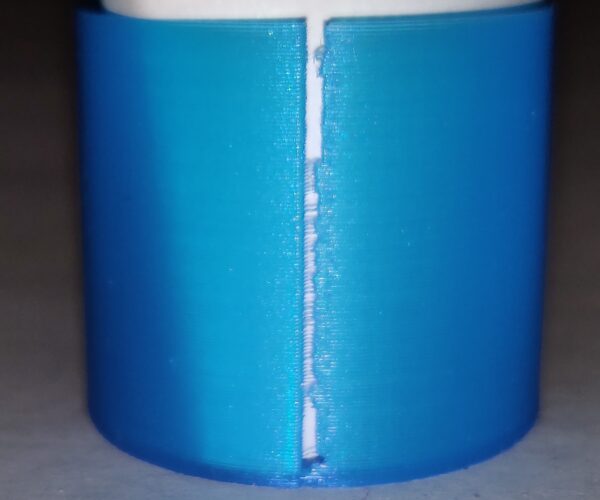

For further investigation I printed cylinders without top-layer.

One ins spiral-vase-mode, which printed perfectly, and one where I just disabled spiral-vase but left the other settings as is.

The last one has a huge gap (~0.8mm) where the layer changes.

Changing the retraction to 1mm closes the gap, but there is still less material (I can feel a valley with my nail):