ideas

Have you tired more than 1 filament? Can you post your zipped 3MF file so we can look at it?

--------------------

Chuck H

3D Printer Review Blog

No 3MF file here

Thanks Chuck, I only have the STL, not sure how to export 3MF, and the GCode is apparently too big to attach here? 14.7MB. This seems to be a problem for me whenever I have any thin, tall columnar prints. But something like a hole in the middle of a thick bit of material seems almost perfect, so I'm wondering if its related to speed or cooling?

how to get 3mf file

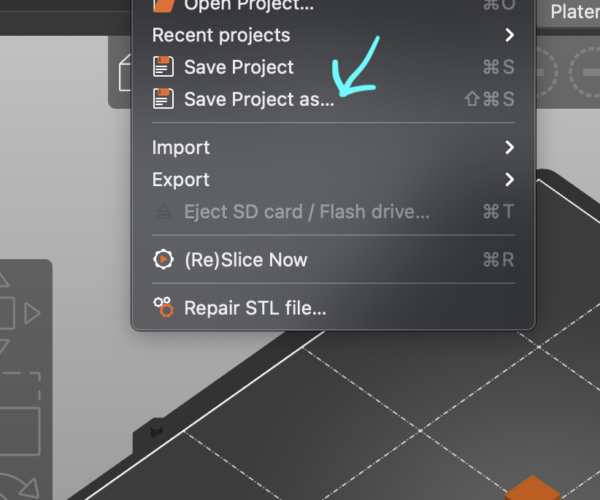

When you import stl file into PrusaSlicer and after you make adjustments, do "File -> Save Project as.." -that will create 3mf file. Zip that file and attach it here.

[Mini+] [MK3S+BEAR]

RE: Help

This might help:

Click on the image to have a visual map:

--------------------

Chuck H

3D Printer Review Blog

RE: Attached 3MF file

Got it, thanks guys. So what do you look for in the 3MF?

Print 3MF

Got it, thanks guys. So what do you look for in the 3MF?

Attachment removed

I look at your settings. I will look at the layers in the slicer. I may even test print it.

--------------------

Chuck H

3D Printer Review Blog

tonight - timed out

I will look at it after work if none of the wizards of the forum beat me to a solution.

--------------------

Chuck H

3D Printer Review Blog

Some thoughts about your settings:

You have only two perimeters, for a functional object that may be subjected to variable loads this may be rather fragile, I suggest three or even four would be better.

For the same reason, enable 'Extra perimeters if needed.'

Your temperatures are practical, the 'Other layers' value could go lower safely but it's not essential.

...but I cannot see anything that would cause the failure you experienced.

The problem seems to have arisen at about the time the printer would have begun slowing to allow the very small amount of extrusion on each diminishing layer to cool. If there was a partial clog this might have magnified the impact.

There is a little bit of what looks like bubbling and light stringing ... I have seen this when a damp filament has been oven dried for too short a time, the outer layers dried and print well but underlying layers remain damp..?

I would try a cold pull in case there is a partial clog, increase the perimeters and try again with a known dry filament.

Cheerio,

Added the extra perimeters

Thanks guys, I've added the following quality settings and just printed another print (albeit not as overrhang heavy) and seems to be fine. I'll have to try a very specific test ( i don't want to print the damn headphone thing again. 😉 ) But I think you're right, additional perimeters should help. I'll update the thread after next column print.