trying to print a cylinder 95% infill with 3d honeycomb, print keeps failing

Hi all ,

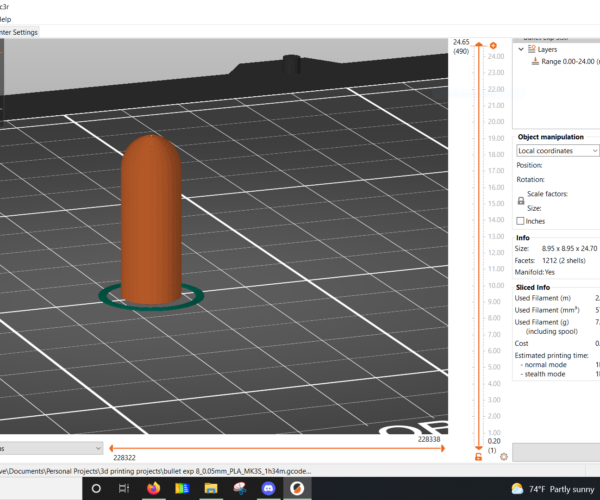

so this is what im trying to print

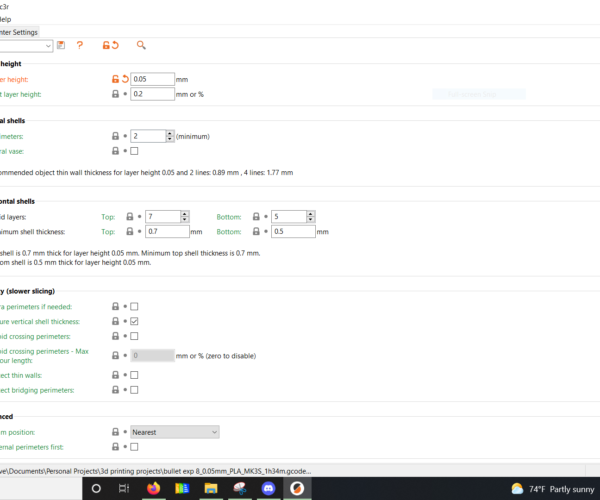

with these settings

and this is what im getting

it seems that the nozzle is contacting the cylinder and drags the print off adhesion and then sticks the whole thing to the nozzle.

thats where im at so far after playing with some settings.

any help would be much appreciated

PS

my first post , please tell me if im in the wrong place

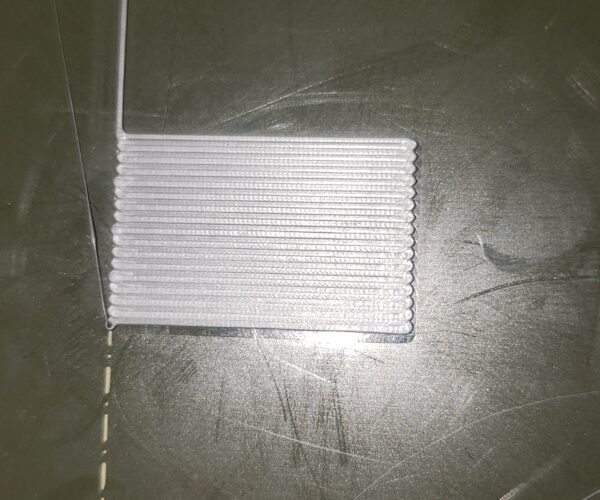

Please show us your first layer Z calibration print.

Cheerio,

First Layer Calibration

Your print is failing because your z-offset from your first layer calibration is not correct. It looks like your nozzle is too low. The rectangle should be smooth and uniform. Take a look at https://help.prusa3d.com/en/article/first-layer-calibration_112364

Mk3S+,SL1S

thanks

thanks . ill check it out right now .

Thank you.

The nozzle clipping the print is often due to poor adhesion, one end lifts off the bed into the path of danger.

Your first layer Z setting is too low, too squished.

At the end of the calibration you are aiming to print a single layer *sheet*. It should be possible to peel it off in one and fold it without the threads seperating. If it breaks into lines it is too high, not squished enough. If it is a single sheet but with wavy lines or drag marks on it you are too low.

I suspect you may have gone too low in trying to overcome prior poor adhesion. From the groups of glitches in your trace I recognise the effects of fingerprints on the print sheet...

Alcohol is OK for maintaining cleanliness but every now and then a more rigorous degreasing is required.

Clean the sheet with dishwashing detergent (Dawn/Fairy) and plenty of HOT water, rinse well and dry with a fresh paper towel. Handle by the edges only.

Why do you need such a dense print with such fine infill?

If you are trying for strength I would suggest 0.2mm layers with Cubic infill at 20% and if you need extra strength select 4 or 5 perimeters.

Cheerio,

update

ok so i adjusted to what i think is more consistent with good first layer calibration. however im still getting the same result .

as the print begins to start the honey comb 3d infill , it seems to fill and squish , causing the filament to pile up and become deeper . The nozzle then drags the filament along with the rest of print off adhesion and drags it around as it tries to keep printing.

for clarity and this is something i should have mentioned before, IM getting good prints with other infills, ( rectilinear ) but honey comb 3d is completely not working right now .

could it be that it doesnt like the 90 percent infill ?

thanks for that . ill give it a go

the density is to increase weight .

ill try adjusting my layer calibration again tomorrow.

3mf and photo

Can you post another image of the new calibration square and upload the 3MF file zipped?

the density is to increase weight .

ill try adjusting my layer calibration again tomorrow.

--------------------

Chuck H

3D Printer Review Blog

thanks for that, ill take it into consideration

thats a great idea ! however , id like to see if i can acheive certain weights with just filament at the moment.

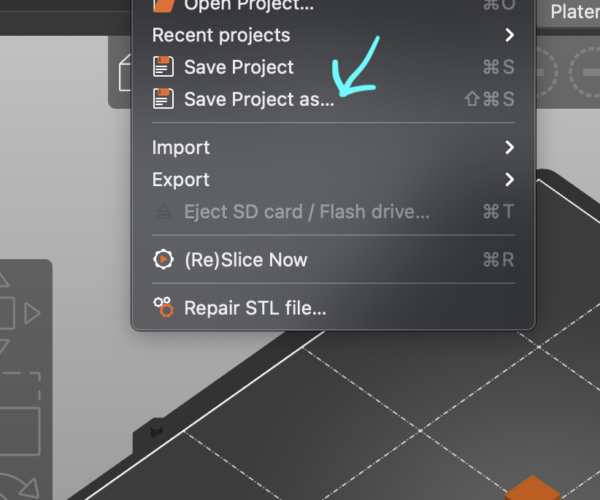

heres the first layer cal i tried this time and the file of the print

You might change your top layer infill to Concentric and Cubic fill for the rest will print faster with less shaking.

Your first layer looks much better but the print sheet needs cleaning.

Cheerio,

ok good to hear

i just gave the bed a wash in dish soap and water. could it be time for acetone ?

Acetone

If you try it, only use a quick spray and wipe. Do not alllow it to stand.

i just gave the bed a wash in dish soap and water. could it be time for acetone ?

--------------------

Chuck H

3D Printer Review Blog

Duly Noted.

Thanks . ill give that a try when i get acetone.

update . no more breaking . upped my bottom layers. still messing up the 3d honey comb

so im getting more or less the same result except now its not ripping the print off the bed. its still sloshing the 3d honeycomb around.

could it be that my nozzle needs to be smaller for finer detail ?

No

It is not the nozzle. Keep adjusting the Z height and keep the bed clean. You will eventually get the right Z height. You could also try a quick spray of hair spray on the bed - Aquanet is best.

so im getting more or less the same result except now its not ripping the print off the bed. its still sloshing the 3d honeycomb around.

could it be that my nozzle needs to be smaller for finer detail ?

--------------------

Chuck H

3D Printer Review Blog

Honeycomb works well at larger sizes for objects where bending bias matters. At this scale and density it requires huge numbers of precise direction changes and the heated nozzle dwells too long over each area for good cooling, cubic would be my choice for fill, much kinder to the printer and significantly faster to print.

Cheerio,