Stringing issue

Hello,

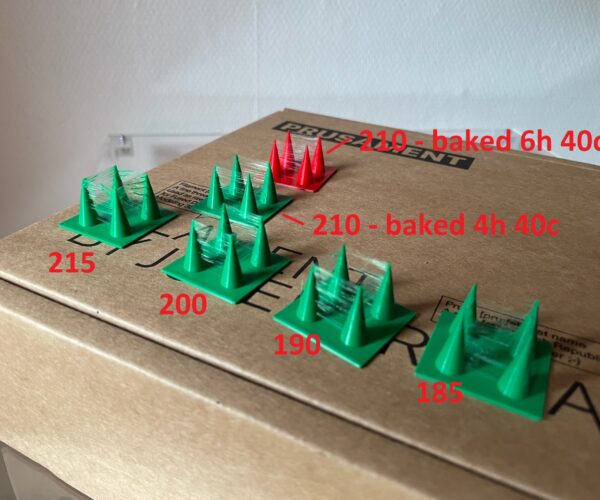

I have some serial stringing issues. Both with PLA (see picture below) and with PETG. I have cleaned the outside of the nozzle using a brass brush and done a cold pull, both as described in the Prusa documentation. I have also run the calibration again. Im using the PrusaSlicer with default settings.

Im pretty sure that I can rule out moisture because I have tried baking PLA for 4 and 6 hours at 40 Celsius (see picture below).

I have no idea what to do to try to fix this issue. So any suggestions would be very welcome! 🙂 Thanks 🙂

That looks like moisture. Baking alone isn't very efficient (it drives moisture both ways) 'though a fan oven helps a lot.

You appear to have tried dropping the print temperature which is the other common cause of stringing.

Whereabouts are you? Is it a high humidity area?

Cheerio,

Moisture

Thanks!

My first print with the green PLA was right after unpacking it from vendor and it also had stringing. Do you still think it is moisture related?

Denmark, its around 50-70 the last couple of months (summer).

If the oven is not good enough, should I try using air tight box with a drying agent? Or what would you recommend?

I don't think it's moisture, because in that case outside tower walls would also have some marks (especially at higher temperatures) -but they seem to be clean. If I'm right about that, then only usual "how to get rid of stringing" is left...

By assuming your Mini isn't modified and you use default slicer settings, here's what I would do is (in the following order):

-check inside of extruder and make sure gear (which grab filament) is clean,

-check and adjust tension screw on extruder,

-try to increase retraction in slicer: from default is 3.2 to 3.8 for example (Printer settings tab in slicer) and check if there's difference in print,

-check if extruder feeds filament properly (by making extruder calibration).

But there's very important question: since when do you notice such stringing?

[Mini+] [MK3S+BEAR]

first print with the green PLA was right after unpacking

You never know how long it has been on the distributor's shelf or how well it was kept.

If the oven is not good enough, should I try using air tight box with a drying agent? Or what would you recommend?

If you are in a high humidity area then a dehydrator is best - a food dehydrator will do if it is big enough.

Repeated short heatings in an electric oven (never gas) are better than one long baking. When the dehydrator is full I sometimes leave the oven door ajar and use the fan at low heat, not an option in a hot summer.

The air tight box with dessicant is a good prophylactic maintenance tool, not a remedy.

Cheerio,

From what I'm seeing in your picture, I'd just take the heat gun to it unless it really ruins your prints. I tend to be a pragmatist with this stuff. I can spend time I don't have to optimize settings, or I just get the job done.

Also, for PETG, you should always expect some stringing.

With that said, I agree with @diem, more aggressive drying may help.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

More information

Hi again! Sorry for late answer, life you know 🙂

And thanks for all the suggestions!! 🙂

So I did the steps suggested by BogdanH Thanks!

-check inside of extruder and make sure gear (which grab filament) is clean,

-check and adjust tension screw on extruder,

-try to increase retraction in slicer: from default is 3.2 to 3.8 for example (Printer settings tab in slicer) and check if there's difference in print,

-check if extruder feeds filament properly (by making extruder calibration).

It did not seem to help. Im not sure if the extruder needs calibration or not. See the cube on attached pictures. It seems fine, but Im not sure.

I cant tell for sure when this started, because I did not do any real stringing tests. So it might have been there from the beginning.

Another thing, is that it seems that the filament is oozing out of the nozzle after print and if I head the nozzle after it has cooled, the filament starts oozing out again. Just a few cm. I have also added a picture of this.

Not sure where to go from here? Any suggestions?

One of the stringing test is with retraction 3.2 and the other is with 3.8

First of, I agree with @fuchsr (above): if stringing doesn't ruin your prints, then take those "stringing test prints" just as information of your printer capability. And even there's some small stringing in your actual prints, you can remove/cut them manually or with heatgun.

However, if there's just too much stringing at default slicer settings and you're sure filament is ok, then I would suggest upgrading to Bondtech heatbreak (about 16€). Let me explain...

From photo I can see your filament ooze is about double of what I have, which I think is related to stringing. The thing is, with original heatbreak, filament isn't melted only inside heatblock (nozzle), because heatbreak temperature is relative high also above heatblock. And because of pressure, all melted filament will ooze out.

What has that to do with stringing? Well, when nozzle jumps from one point (tower) to another, there's very short filament retraction -which actually pulls filament back (from nozzle). But if there's too much melted filament inside heatbreak, then retraction has very limited effect. To simplify: stringing is actually oozing at retraction. I recommend watching this video for better understanding.

Btw. Make sure thermal paste is applied on upper part of heatbreak.

[Mini+] [MK3S+BEAR]