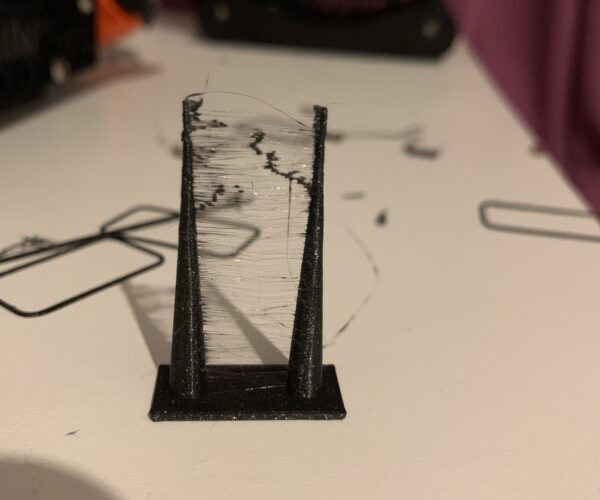

Stringing

I ran the stringing test and clearly there was a lot of stringing I would like to reduce this a lot how could I do so? The settings were 5mm retraction at a speed of 80mm/s with a retraction befor wiping of 65% and a detraction speed of 40mm/s everything else was factory settings. Also using Prusament PLA

RE: Stringing

Dry the filament.

It may be heresy but I find those stringing tests to be utterly useless--unless you enjoy going down a rabbit hole of optimizing a multi-dimensional parameter space just to find that nothing makes as much difference as drying the hell out of the filament.

Okay, I may be exaggerating a bit. But the answer to "what is the best set of parameters" is clearly "it depends". I do find though that turning off Lift z frequently seems to help--unless it doesn't 😇

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Stringing

Ok, I’ll dry the filament in the oven for a bit today and see if there’s a difference. Thank you!

RE: Stringing

Yeah, a good filament dryer is needed for moisture in filament. I haven't had luck with the cheaper versions and eventually bought a PrintDry.. But there are other things that can cause stringing as well. If your nozzle is old and it has become quite worn, it can cause stringing in most filaments. My brass nozzle got quite worn in 6 mo. and was 0.55mm and almost every PLA and PETG filament I owned started stringing. You can measure the extrusion to see what your 0.4mm nozzle currently sits at. And your nozzle temp could be a bit high, try reducing 5-10. Moisture is certainly the most common..

RE: Stringing

Interesting! What type nozzle would you suggest a brass or steel? Also what size would you recommended 0.4 or 0.6?

RE: Stringing

I just replaced the brass 0.4 with another brass 0.4 because I have them.. Some have gone to a better metal.. I can't remember the details.. there is NOZZLEX, but it requires modifying the default profiles.. what people are recommending, other than brass, is a chromium one, I think, from a couple of vendors.. I don't have specifics.. but info is in posts on forum if you search.. Your nozzle may be fine.. just check its extrusion and visually inspect (tough if its full of black crap) to see if it is worn.

RE: Stringing

Six months feels short for a brass nozzle but of course it depends. Next step up from brass is nickel-plated copper. I liked them, similar to brass but seemed to attract less PETG in my hands. If you're going to print abrasive materials, you'll want a hardened steel nozzle like the Nozzle X. Wasn't for me, as it required a lot of adjustments. These days I run tungsten carbide nozzles from 3D Maker Engineering and Spool3D on all my printers. Pricey but the advantages of a hardened steel nozzle with the thermal properties of a brass nozzle.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/