Printed model is smaller than designed part

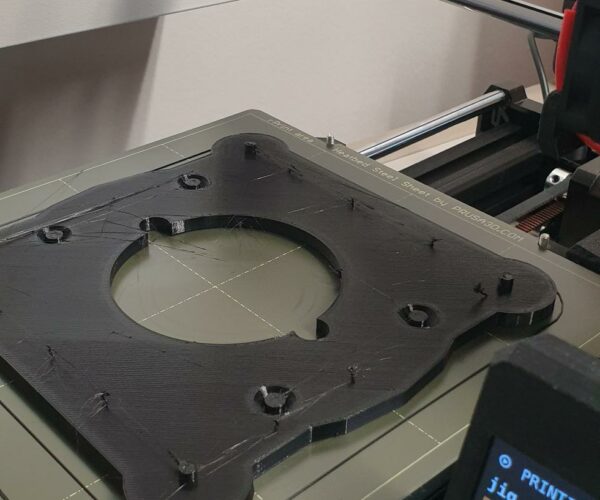

Hi you all, I've designed a router jig to make a MFT table using a pegboard.

The printed model is 1,23mm (X and Y) smaller than intended. For the Z it was intended to be 5 mm high and it measures only 4,8 mm.

RE: Printed model is smaller than designed part

Everything is going to be wild guesses without more data. If you upload your project as a 3mf file, you're likely to get better advice. In Prusaslicer, go to File/Save project as, to create the 3mf file. Zip compress it (right click Compress on Mac and Win11, right click Send to/Compress on Win10) to turn it into a .zip file, which you can attach to a post on this forum. The forum software does not accept .3mf files, it has to be a .zip file.

At minimum I'd print a hollowed out calibration cube to calibrate my extrusion multiplier.

Also as an aside, 100% infill is almost never needed. I'd rather add a couple of perimeters and stick with 20% or less infill.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Printed model is smaller than designed part

Couldn't spot anything obviously wrong with the 3mf file.

While the 0.2mm for Z wouldn't surprise me, the XY shrinkage (at about 1%) is higher than I'd expect. As I said before, I'd start by making sure the extrusion multiplier is correct. Assuming the printer is unmodified, I wouldn't think calibrating e-steps was necessary.

Could be thermal contraction. There's a recent quick discussion thread here on the same topic:

I would also try 4 perimeters, 20% gyroid infill, as the high infill may contribute to contraction.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Printed model is smaller than designed part

Thanks foor looking in to it. meanwhile i've printed the 20mm calibration Cube and measured with my cheap digital calliper it seems to be oké. I will reprint the router plate with 15% infill. Are there certain infill patterns that are recommended?

Whilst gyroid is an excellent general fill I generally use cubic for distributing stress around practical parts. Adaptive and support cubic are mostly about top finish.

@fuchsr is right about fill, 100% is almost always a mistake.

Cheerio,

RE: Printed model is smaller than designed part

Take a look at these knowledgebase articles:

https://help.prusa3d.com/en/article/inifill-patterns_177130

https://help.prusa3d.com/en/article/infill_42

Great discussion of strengths and weaknesses of each infill type and impact of infill vs perimeters.

I found gyroid and adaptive cubic to be the best all-around infills.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Printed model is smaller than designed part

thx, it is now printing with 15% gyroid infill. We will see when the print is finished and cooled down.