PLA adhesion problems with small sections

New to 3d printing here. So I'm trying to print this spider: https://www.myminifactory.com/object/3d-print-hanging-spider-138587 or the doors to this box: https://www.thingiverse.com/thing:1559232

The same thing happens - when ever I'm printing pieces with small initial bed surface areas they routinely won't stay stuck. I'm taking the defaults for PLA 215 deg tool and 60 deg bed temp.

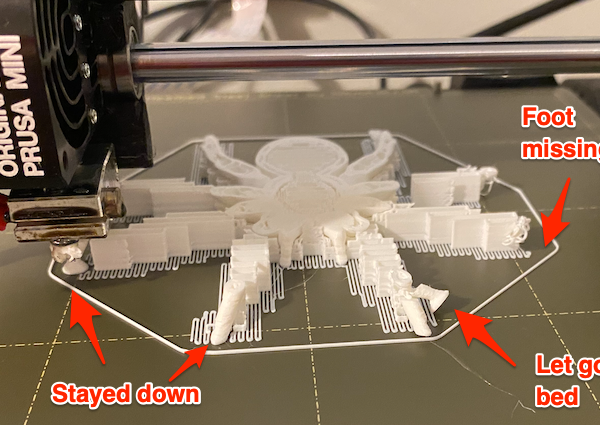

Example from the spider: 2 of the feet let go, other 6 are fine.

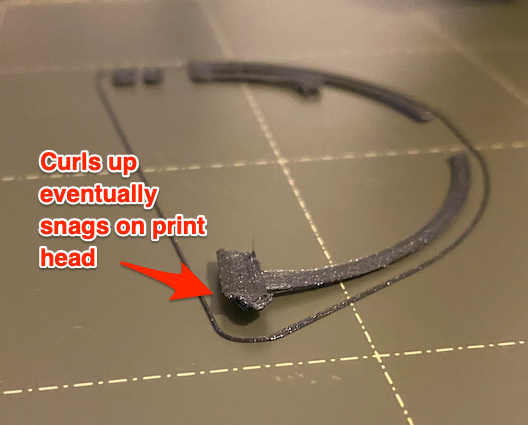

Here's the door from the venus box:

the settings I used for the spider:

STL view of what let go:

It's almost like I need a raft underneath or something to help it stick/hold better. My other prints have been amazing so all and all I'm very happy with the machine, just looking to get smarter/better with it.

Any tricks or settings I should try?

Thanks,

Rich Whiffen

RE: PLA adhesion problems with small sections

Ok so I just found this article: https://help.prusa3d.com/en/article/skirt-and-brim_133969/ and am trying a brim. So far it looks to be helping.

RE: PLA adhesion problems with small sections

- clean the bed with dish soap and rinse with a lot of hot water, then ensure no fingerprints are present in the print area

- lower a bit the nozzle

- increase a bit the first layer temp

if none of the above fix, it could be the filament so the brim finally solves.

RE: PLA adhesion problems with small sections

@turro75

Add: use a non-scratch scrubber. It can help to remove some fingerprints.

--------------------

Chuck H

3D Printer Review Blog

RE: PLA adhesion problems with small sections

Sometimes with small part first layer issues I find (after cleaning the bed well) printing at 33% speed for the first 2 or 3 layers really helps.