PETG stringing - how to fix??

Hi All,

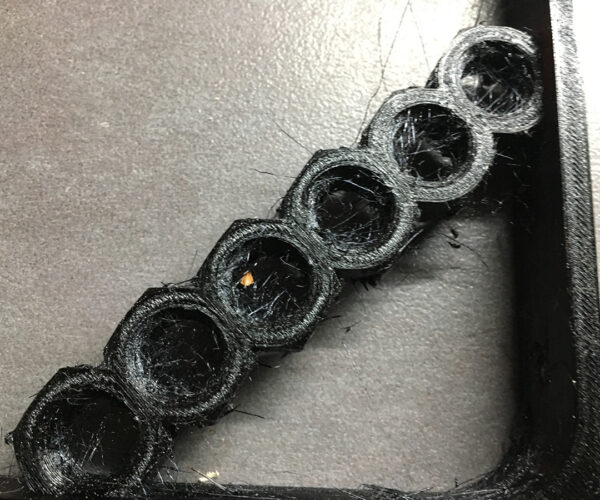

Trying to print a shelf bracket in PETG (for strength) but experiencing a lot of stringing.

I have a filament dryer and have dried the filament for 3hrs prior to use.

Here are images of the bracket in both PLA (Prusa Galaxy Black) and PETG (eSun Black).

The PLA looks amazing. The PETG is heavily stringed.

I downloaded a Stringing tower to confirm that the PETG settings were less the optimal .

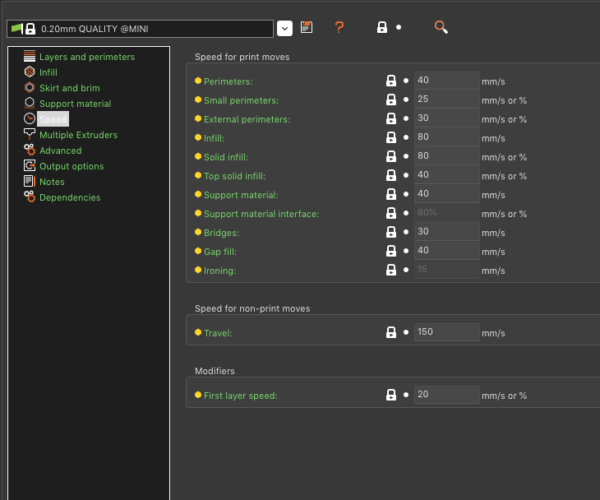

The settings currently being used are the DEFAULT PETG settings in Prusa slicer.

Print Settings : 0.20mm QUALITY

Filament : Prusament PETG

Printer : Original Prusa MINI & MINI+

Please advise what should / could be changed to achieve a better result in PETG.

Wanting to achieve the same print quality as PLA if possible.

Thanks in Advance.

Matt.

Printer : Prusa Mini +

FW : 4.3.2

Plate : Textured PEI Satin.

Dryer : Sunlu

https://www.sunlu.com/products/sunlu-filament-dryer-s1

Prusa Mini+ - Fw. 2.3.1 - PrusaSlicer 2.3.0 (Mac) - Filaments PLA / PLA+ / PETG.

That looks like damp filament. Look up some of the many threads here about drying filament. PETG will always string a little but a second or so with a heat gun sould be enough to clear it.

Cheerio,

still looks damp

I agree with @diem that that PETG filament still looks damp. What device did you use to dry it and at what temperature for the three hours?

Three hours is nowhere near long enough for bulk filament, it might be enough for a few loose coils.

Cheerio,

dry box

I agree with @diem that that PETG filament still looks damp. What device did you use to dry it and at what temperature for the three hours?

I can suggest a few options:

There are probably other options. I dry my filament in #1, 2, and 3. I store unused rolls in #1. I absolutely love number 2 and use them for very hydrophilic or water-sensitive filaments. It is great for Nylon and PETG with CF. These filaments really absorb water and quick degrade printing. I own 9 of number 4 or equivalent. There are atleast 3-4 different manufacturers of dry boxes link #4 to include eSun, EIBOS, Polymaker, Sunlu, SOVOL, and JAYO. They are all pretty much the same and they are more to print from than dry already wet filament. I would recommend a cheap food dehydrator if you do not intend to run them all the time.

Do you have any questions?

--------------------

Chuck H

3D Printer Review Blog

Cheap Dehydrator

I would recommend a cheap food dehydrator if you do not intend to run them all the time.

My suggestion for cheap food dehydrator that works well for me:

Regards,

Mark

Diem response.

Thanks Diem, I'll look at Heat Gun as well. But wasn't expecting this MUCH stringing.

Prusa Mini+ - Fw. 2.3.1 - PrusaSlicer 2.3.0 (Mac) - Filaments PLA / PLA+ / PETG.

Re: Still looks damp.

As per the original post. the Dryer is the Sunlu filament dryer. Temp was 50˚C.

I'll extend the time of drying. The filment is an a garage and it is winter here (ie. Southern Hemisphere).

Prusa Mini+ - Fw. 2.3.1 - PrusaSlicer 2.3.0 (Mac) - Filaments PLA / PLA+ / PETG.

Re : Dry Box.

Thx for the response.

As per the first post, using a SUNLU filament dryer. 50˚C. I'll try extending the dry time.

Query, if I may, do you own a mini? and if so could you supply an image of PETG print from the mini?

Thanks.

Prusa Mini+ - Fw. 2.3.1 - PrusaSlicer 2.3.0 (Mac) - Filaments PLA / PLA+ / PETG.

sunlu

Thx for the response.

As per the first post, using a SUNLU filament dryer. 50˚C. I'll try extending the dry time.

Query, if I may, do you own a mini? and if so could you supply an image of PETG print from the mini?

Thanks.

The Sunlu box is ok, but I prefer a food dehydrator for drying. They work better. The Sunlu is better at keeping it dry while printing.

--------------------

Chuck H

3D Printer Review Blog

The Sunlu box is ok, but I prefer a food dehydrator for drying. They work better. The Sunlu is better at keeping it dry while printing.

-I agree on that.

Sunlu, eSun, etc. aren't meant for "forced" drying -they're meant to be used for already dry filament and so prevent filament to catch moisture during print. And for that only, they're quite overpriced (compared to food dehydrator).

[Mini+] [MK3S+BEAR]

RE: Food Dehydrator Time and Temperature

I dry my PETG filament in the dehydrator I linked for at least 8 hours at 65 C (149 F) to get best results. After an 8 hour print with the filament in free air, I can start to see a difference in stringing getting worse. I am in AZ and have air conditioning, but we are in our rainy season, so the humidity in the house probably gets up above 40%. If you are in a really humid location, consider a dry box that you can keep the filament in while printing. This time of year, I throw it back into the dehydrator after about 8 hours of printing if I care about the print quality. Injection molders dry PETG for 4 hours at 65 C, with basically hot, dry air blowing all around the pellets, not on a reel as we have. From what I can find, 65 C is the hottest you should use, time and airflow can be increased.

Regards,

Mark

Never Stringing on PETG

I have been using PETG without any stringing or cosmetic issues for a couple years by confronting the science head-on.

The hygroscopic forces holding water molecules on and in PETG cannot be meaningfully removed with desiccant, gentle heating or soft vacuum techniques. As evidence of this, look to the polymer industries using pellets. Industry's efforts to remove the moisture that would affect the appearance and properties of their products cannot be overcome by methods generally advocated to our 3D printing community.

Industry's cost effective method to dry PET is to use very high temperature air blown into a hopper which is then filtered, cooled, passed over desiccant and then re-heated for another pass. The desiccant is frequently re-charged by heating it at high temperatures.

Using a high vacuum for extended periods of time to dry PET has many advantages in performance, but it is difficult to incorporate in the production flow of most factories.

For us, the 3D printing enthusiasts, we can accomplish storing our filament under high vacuum for meaningful periods of time, but the expense to create a satisfactory vacuum chamber is high. However this is the method I use.

I have created a few vacuum chambers in which I store my filament until needed. 3 days stored at 1000 microns produces PETG that can be out of chamber in a printer for about 2 days without noticeable degradation. 2 of my chambers are based on pressure cookers, and one uses a stainless steel inner pot from an Instant Pot device. In practice, each chamber costs about $100 per filament roll storage capacity. Additional expense comes from a 2-stage vacuum pump, micron meter, and expendables (pump oil, vacuum grease, etc.).

Quality comes from attending to the details, and using the right tools.

I hope this explanation helps others.

RE: Never Stringing on PETG

Sounds a bit extreme to me. I bought Prusa Mini to have an affordable 3D printer. Additional costs are now somewhere close to 100€, had to buy IPA, IKEA lack tables, acrylic for walls, and a food dehydrator to occasionally dry up the filament roll in use. I have planned on shopping some plastic storage bags where you put small desiccant bag with the roll and pump air out of it.

No doubt vacuum chamber works, but for a hobbyist like me that will be too much. If I had the space for this hobby, then perhaps. I could use vacuum pump in another hobby of mine, but as I don't have the space I need for that kind of activity I haven't gotten one. Those pumps aren't necessarily expensive and I think you estimation for storage per roll is about right.

So for now I settle on my slightly modified food dehydrator. Here the air is dry during winter and I can get by for a long time without needing to dry the filament. Now at the end summer things are at their worst as air is rather warm and it is raining.

RE: RE: Never Stringing on PETG

I wholeheartedly support the perspective that storage of filament in a moderately high vacuum is a more extreme solution than most folks would employ. When I first switched from PLA to PETG, I suffered from stringing and oozing, just like so many others have. The material's properties are so much better than PLA for the parts I build, that I wanted to determine how to minimize or eliminate these issues. Being very pleased that this approach gets the very best that I could wish to expect from PETG, I wanted to spread the word.

For myself, I have only begun to research this method.Outgassing of the moisture is not the only thing that being removed from the plastics that are inside the chamber. Under the influence of high vacuum, the filament and the spool also outgas unpolymerized monomers, plasticizers, stabilizers and other additives. It is likely that these chemistries depart the base material much slower than water molecules, but I hope to find a sweet-spot where the moisture is sufficiently removed without jeopardizing any of the preferred properties of PETG. At that point I should be able to determine: (1) A target vacuum range for PETG (2) The minimum duration under vacuum necessary to assure good results with PETG (3) If long-term storage is detrimental to PETG filament (4) How long is too long for retaining the desirable properties of PETG while it is stored in a vacuum chamber

Thank you for your comments.

RE: Never Stringing on PETG

Please keep us posted on your findings either on this same thread or perhaps on some wiki page (post the link here). How about drying the filament to some extend and then storing it in normal pressure, but in some shield gas like Nitrogen or Argon? Then you would not need pressure chamber for each roll, just for the rolls currently under drying. For storage in shielding gas under normal pressure those storage bags with a went might be sufficient. Move to roll from vacuum chamber into bag, put a desiccant in with it. Close the bag and pump air out with the hand pump. Close the valve, attach say Argon bottle to valve, open valve, let some Argon in. Close the valve and you are done.

Sounds complex and it is more complex than having a vacuum chamber for each roll, but with more than few rolls it would keep the costs down. And likely save some storage space, those vacuum chambers won't fold when not in use.

Somewhere here there is a lengthy thread that went down the path of drying techniques including vaccum chambers

If you're up for a bit of searching, there is a lengthy thread here somewhere in which various methods of drying with and without vacuum were tested, and (IIRC) the conclusion is that it wasn't worth the effort if using any of the consumer-grade options readily available.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Somewhere here there is a lengthy thread that went down the path of drying techniques including vaccum chambers

Ok, I guess I didn't search enough. Forum tends to get bit fragmented, same kind of information is in various places. I'll look again.

RE: Somewhere here there is a lengthy thread that went down the path of drying techniques including vaccum chambers

Likely this, at least it is long:

https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-general-discussion-announcements-and-releases/drying-times-and-temps-in-dehydrator/paged/1/

Yep, link to conclusion post

Likely this, at least it is long:

That's it. Conclusions end about here. You might reach a different conclusion with different equipment, but I've yet to run across anything concluding vacuum drying with typical consumer-grade equipment is a life changer.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…