Mini nozzle clogging with PLA -> retraction grinding problem?

Hello Guys,

Unfortunately I have some problems with printing PLA on the Mini.

Usually I print with PLA and PETG, I had no issues with printing PETG so far. But there is a problem with printing PLA.

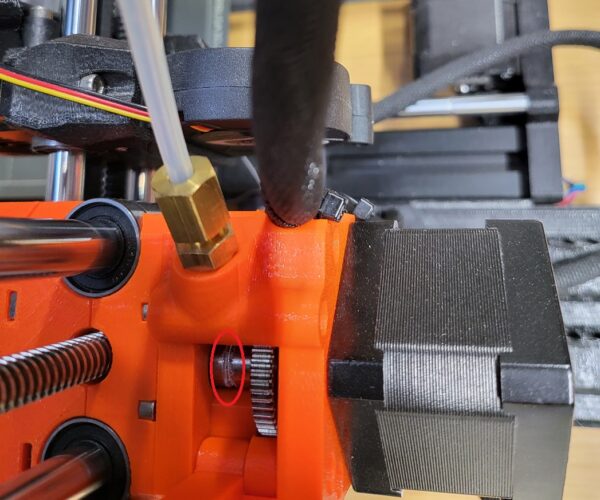

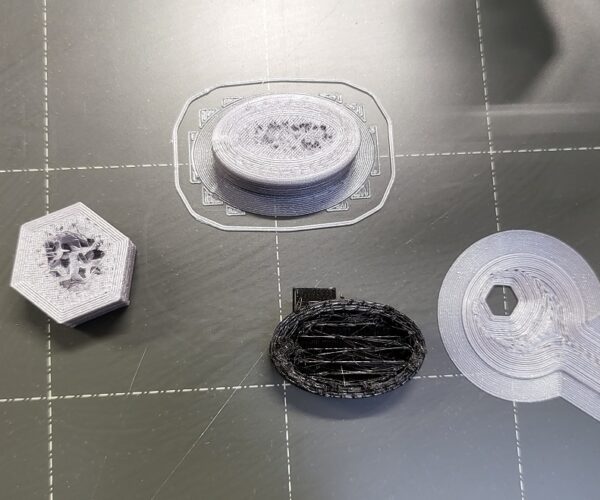

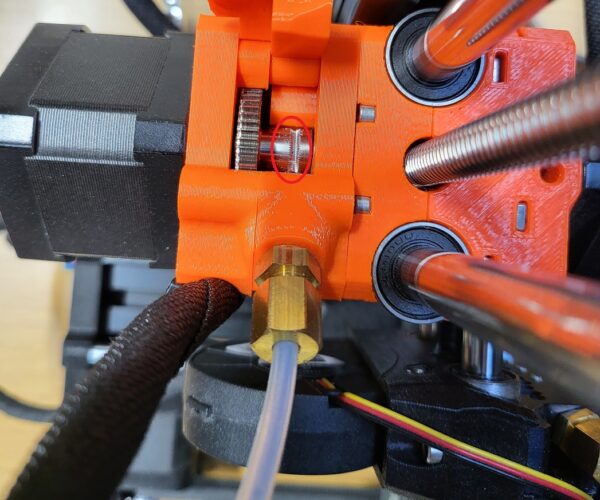

In my opinion the retraction of the filament may cause this problem. It seems like, because of the retraction, the filament extruder disc grinds part of the filament off.

This happened several times now. I don't know what to do but clearning the extruder disc, but it happens again and again.

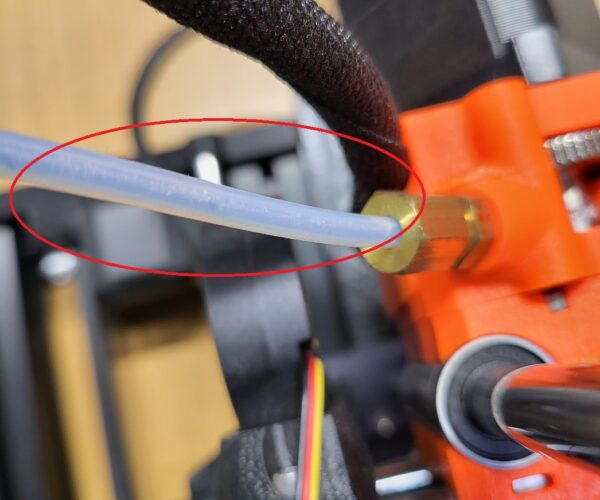

It looks like that the grinded off filament gets transported into the PTFE tube and causes the nozzle to clog, this leads to bad and unusable prints.

Does anyone know how to solve this problem?

I tried to take some pictures to show the problem.

Thanks for reading and helping

Daniel

RE: Mini nozzle clogging with PLA -> retraction grinding problem?

Been trying to solve the exact same issue. PETG prints much better than PLA, since PLA clogs at some point.

Never figured out why though. Hopefully we can get some answers in here.

Prusa Mini FW6.2.4

RE: Mini nozzle clogging with PLA -> retraction grinding problem?

When I had this problem it was caused by the short Bowden tube that goes in the heater. You get the grinding from the extruder and all the symptoms you describe. Swap that tube over with the spare and see if that fixes the problem.

RE: Mini nozzle clogging with PLA -> retraction grinding problem?

I had to replace my extruder for this opensource (dual gear) model (see link). I would upgrade to this one to solve many problems related to Prusas design choice. I couldn't solve it with the original extruder. Maybe this link helps you:

https://www.printables.com/model/118593-cm3d-extrusor-mini-fs

With this upgrade you will also be able to print TPU

RE:

When you have problems printing with a lower temperature filament after using a higher temperature filament, it is possible that some of the higher temp filament is stuck in the hot end and the lower temperature filament can't push it out.

Try this:

Remove the fitting from the long PTFE tube and do a cold pull, as found in the Prusa instructions for a cold pull:

https://help.prusa3d.com/article/cold-pull-mini_126399

Start step 7 (pushing the filament) immediately while the hot end is still at the max temperature and see how hard it is to push the filament in. It should not be difficult. If it is the hot end is clogged and you install a different extruder that pushes harder, that is only covering up the problem. Vary the hot end temp and see if a hotter temp pushes the clog out.

When I switch to a lower temp filament, I load the lower temp filament at the higher temperature, purge, remove and reload at the lower temp. For example, after printing PETG, load PLA but tell the printer it is PETG. Purge, unload the filament and then reload telling the printer it is PLA.

The hot end must be assembled exactly as Prusa describes and the PTFE tube in the hot end may be damaged and need to be replaced. Try those also, before you start modding. The Mini can do what it says in bone stock condition, even print TPU, if assembled and used precisely as described in the documentation.

You don't have to replace parts, but assemble the hot end per these instructions:

https://help.prusa3d.com/guide/how-to-replace-a-heaterblock-heatbreak-mini-mini_122769

Replace the PTFE tube per these instructions:

https://help.prusa3d.com/guide/how-to-replace-a-hotend-ptfe-tube-mini-mini_119449

Regards,

Mark