I can't print good quality architectural model. Window openings sagging.

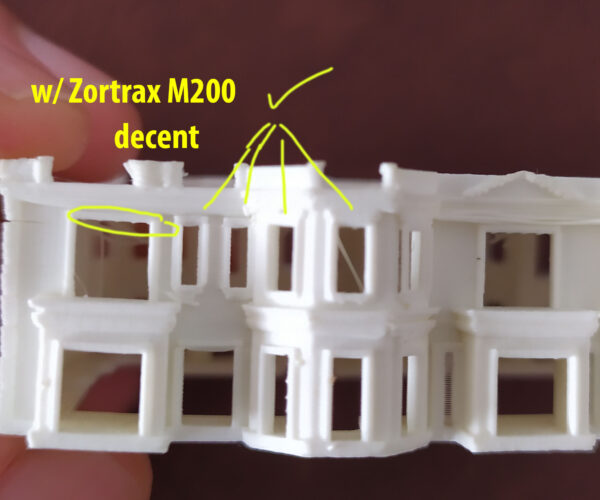

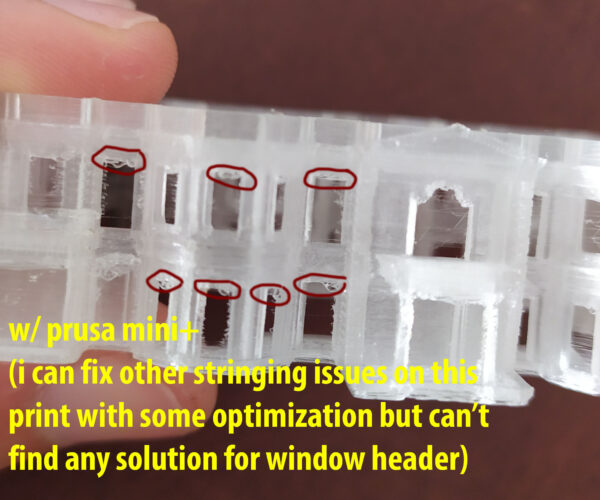

I'm an architectural model maker and i have resin priters & FDM printers. Few months ago i bought Prusa Mini+ and while it has really good overall my architectural building prints has a big issue. Upper part of the window openings (upper head jamp/Header) always sagging. I want to go full prusa on my FDM printers but this issue stoping me from selling my zortaxs and buy more prusa. Any idea why? Some guy on reddit suggested that its happening becasue mini has poor cooling system thats not powerfull as prusa mk3s. not sure if thats the case becasue i can get decent details with closed fan with my zortrax.

Pretty standard

These are pretty standard results. You could try altering the cooling system.

--------------------

Chuck H

3D Printer Review Blog

No matter what printer brand, high detailed miniatures are hard to print with filament printer. If two printers are properly assembled & adjusted, then the differences in results are usually negligible and depend on settings in slicer. It happens someone says "this was printed fine on X printer and bad on Y printer, even settings are the same".. and maybe he forgets the fact that 1st printer printed at 5°C lower room temperature (is just an example). And then, using same settings on different printers many times isn't the best idea -I mean, there are physical differences among printers.

Of course, having a "better" printer is always of benefit (more precise regulations, better cooling, etc.), but we have what we have. So we can only experiment with settings and trying different filaments until we find "the right one" for our projects. And we need it dry!

I have no experience with resin printers, but from what I saw in reviews, such miniatures seems to be perfect candidate for it -just thinking aloud here.

Sorry, no advice here.. except try different filament (there are differences in brands!) and play with settings (i.e. +/- 5°C again can make a difference on such small object).

[Mini+] [MK3S+BEAR]

The zortrax has 2 fans cooling the part so its no surprise the bridging is better. There's several reasons its £ 1790 as opposed to £370 for the mini.

Its sagging more absolutely due to the differences in cooling. While in my opinion the mk3 has better cooling than the mini I wouldn't call the cooling on the mk3 stellar either. My modified cr10 can do 120mm+ long bridges with its petsfang duct and bigger fan.

You are going to have to modify the mini if you want better.

Cooler mod for Mini

There's a simple cooler mod which might help: https://www.prusaprinters.org/prints/34475-prusa-mini-rhd-fan-duct-rev-c

Personally haven't tested this yet, just printed the nozzle. Once my filament dries, I'll try one part that was previously doomed with normal quality settings with Mini.

Re: Cooler mod for mini

Once you visit the site for the mod, check the pictures. Some use two coolers with Mini.

@lupin

Keep us posted.

I've tried a few "improved" shroud designs for the Mk3S, none of which made any truly quantifiable difference in my hands. I've printed some of the standard overhang etc test models, improvements were marginal at the very best, sometimes worse. I'm back to stock shrouds on my machines. Haven't tried any of the Mini mods though but again, I'm not holding my breath for any persistent improvements in quality.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Re; keep us posted

Will do. First test print is now in progress. Print will take some 8 hours. I'm away when this is finished, so will likely tell results on Sunday. Test print is cookie cutter which I have tried to print several times and got success only when I drop temperatures by 10 degrees and use speed-profile. Now trying it out with standard quality-settings and default temperatures. If this comes out as it should, I will keep this modification.

The modification looks like it could be improved a bit, but my skills with CAD are still lacking so much that it will have to do as is. Also, another cooling fan does not cost much nor is it heavy, so running dual cooler is something I'm willing to experiment with later.

I'm printing with PETG (Prusament Carmine Red at the moment), so the result might differ from what you get with PLA or other materials.

About test print

Test was mostly successful. Compared to speed settings with lower temperatures this has the obvious differences: sides are smoother due to lower layer height. Maybe the higher temperature affects also (better melting with previous layer). Seems to be at least as strong as the speed printed version. Anyway, there are too small patches where the surface is not smooth, but rather matte almost as if the there had been tiny bubbles when it settled. I would rule out moisture in the filament, as that roll was in the dryer for several days and when the print was started the roll of filament was still warm from the dryer.

I'll try to get few pictures later. I have some troubles with my camera at the moment.

To me this fan duct modification seems to be an improvement, so I will keep it installed for the time being.

Try Variable Layer Height and Modifiers

A few things to try are variable layer height and modifiers. For example, you can add a box modifier to slow down the speed while doing bridges in a particular area. If there is one area that is not great, modify just that area and let the rest print faster.

Variable layer height is not quite as smooth, but it also makes difficult parts better, while printing easy parts faster.

Regards,

Mark

RE: Try Variable Layer Height and Modifiers

I have variable layer height on by default. Haven't tried modifiers but might next time. Anyway, Original Poster had issues with overhang, and I think this modification could help him too, but you never know before you try. There's more discussion about these and other mods to cooling here: Check that out.

Personally I think I keep this modification and might even try to improve on it, obvious and easy way is to install second cooler as I now have the original cooler mount free.