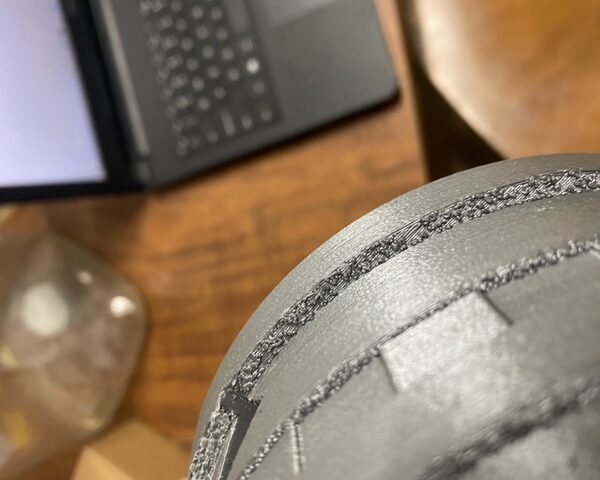

RE: How do i fix this? Both areas are where supports attach

contact distance is .25

pattern distance is 3

interface layers is 4

xy seperation 75%

everything else is default

RE: How do i fix this? Both areas are where supports attach

Unfortunately, supported layers are never going to look as good as layers printed without overhangs. Since the support has to be removable, there has to be a gap between supports and supported layers. That means the supported layer is literally printed in thin air. You've increased that z contact distance to 0.25mm which many of us do to improve ease of removal, but that increases the amount of free air. The supported layers print without any squish onto layer beneath, so have a circular cross-section and tend to sag slightly.

Other slicers handle supports for flat areas a bit better, at least for now. I use ideaMaker for areas with large flat surfaces that need support. PrusaSlicer is improving constantly and quickly, and supports will no doubt get some additional attention soon. It's one of the few remaining problem areas for PrusaSlicer.

Here are the common options:

- You can try re-orienting the part to reduce the need for supports.

- If you are designing the parts, you can design in some easily remove "sacrificial supports".

- You can slice the part into smaller portions that don't require supports and assemble them after printing.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan