Flow calibration - depend on nozzle temperatures ??

Hello to all,

I have question about flow calibration.

I observed that when I raised nozzle temperature from 210 degrees C to 215 degrees C the flow changed in my opinion. I wanted to obtain better connection between layers.

I observed more incostitient flow on layers who are on small parts - on big, long walls is also nice and smooth but on short, small walls is ugly - wall thickness is bigger than on long parts of wall. This is like overextrusion.

It's normal ??

How to deal with that ?? Lowering the flow ratio ?? Or lower the nozzle temperature ??

Soon I will upload some photos.

RE: Flow calibration - depend on nozzle temperatures ??

Perfect print as should be 😀

The same model, parameters only another spool of filament from the same producer - bumps appeared 😥

Can You help me ? It’s flow issue or temperature is too high for that new spool ?

They only appears on tiny, short surfaces 🙄 Long surfaces are perfect in both cases 🤔

RE: Flow calibration - depend on nozzle temperatures ??

I can't edit my post 😇

I don't know what's main root cause of that....

Is temperature is still too high ?? Or flow isn't proper for that new spool ?? It's amazing that bumps only appears on tiny, short layers - on big, long layers everything is okay as You can see on first (upper) picture.

Can You help me please ?? Do You have any ideas how to solve that ?? 😊

RE: Flow calibration - depend on nozzle temperatures ??

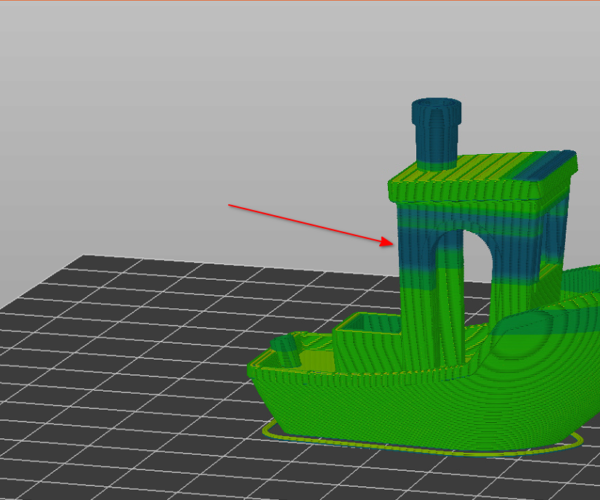

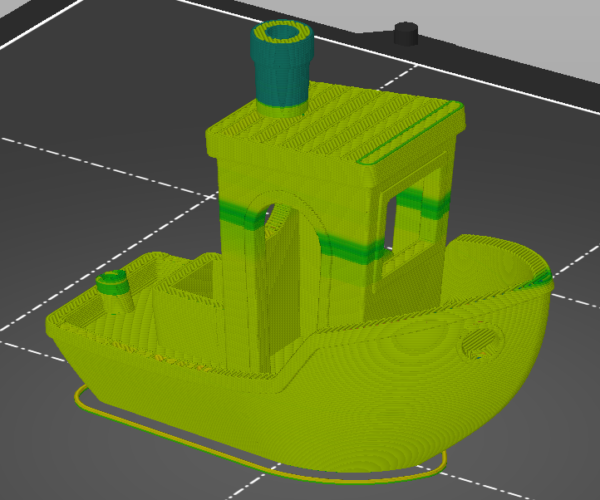

Check the Volumetric Flow rate after slicing in your slicer. I have similar problems on my Benchy where I have lower flow rates calculated by the slicer (see below picture). I have either over- or under extrusion in these areas causing uneven surfaces even if the other parts of the printing is perfect.

As a workaround I have played with the Min Print Speed settings (under Filament > Cooling settings). For example in this case I have raised it a bit and that caused a bit more even flow rate in slicing for this model, although I guess it's rather some differences in between the slicer profile - or what the profile thinks about your printer - and your capabilities of the printer - which could be anything coming from the extruder/heatbreak/nozzle/temperature/etc. setup. Maybe your printer needs a check if everything is correct, or maybe a calibration is required for that filament. I'm in the pursuit of the root causes of my case as well at the moment, but at least I have identified something which could be a possible root cause, and at least I have a workaround - kind of.

RE: Flow calibration - depend on nozzle temperatures ??

Same topic, some explanation:

RE:

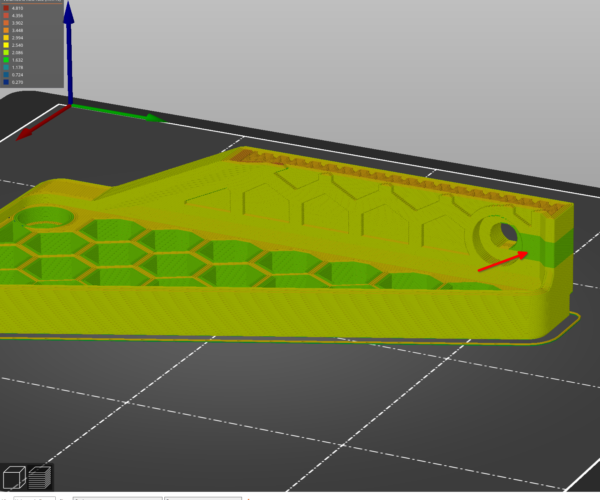

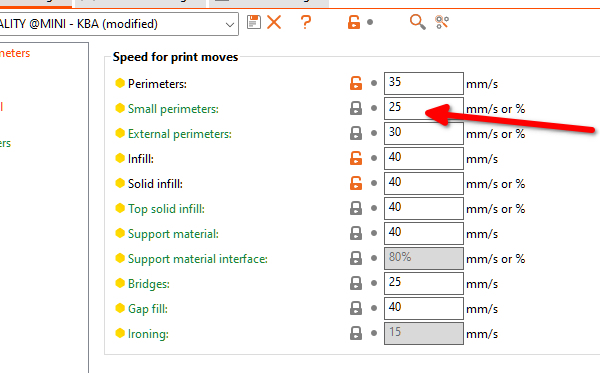

I think that small part is printed with a lower speed - and I guess in your case it's controlled by Print Settings > Speed > Small perimeters.

I don't know if it's a problem with the printer setup which results problems on lower speeds or it's rather a problem with switching from high to low, low to high all the time on those affected layers. It could worth a test to print something all low speed and check the result if you have bumps or not.

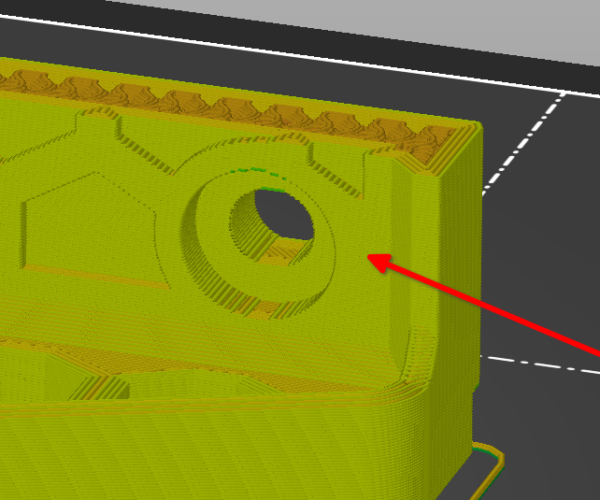

I noticed the same thing on my prints next to screw holes, small separated parts in different prints. Whenever the volumetric flow changes from high to load or vice-versa it could cause different issues on small separated areas.

What you can do is to check the Volumetric flow after slicing and try to resolve the bigg differences. For the above problem you might want to test if you raise the Small perimeters speed a bit.

The filament cooling settings could also play a part - the "Slowdown if a layer print time is below" setting could lower the flow from time to time on unwanted areas also.

What could also result similar cases - ironing inside a model (Print Settings > Infill > Ironing Type > All top surfaces << try to avoid this). After ironing you can easily have underextrusion in the next layer - this is kind of a known 'bug' of ironing.

In this case I've raised it from 25 to 30 as I had bumps on the above 'green' area, and the result:

And there were no bumps on the print - tada.

RE: Flow calibration - depend on nozzle temperatures ??

When I checked the VFR on my standard benchy the errors do match up almost exactly with low flow rate areas, I've tweaked it a bit to get this much more uniform flow rate and will see how that affects things, unfortunately I'm off out so won't be able to test this until this evening.

Still odd that I thought I had the revo dialled in pretty great with the V1 setup, I'm only having this issue since I installed V2, perhaps the extra hotend cooling capacity is making the effects more pronounced?