Chewed up edges on PETG prints

I'm having a problem with (particularly) lower rounded edges on overhangs getting "chewed up".

A good example of it is with this picture:

This is the lower curve (bed side) of a GoPro style bracket. (The STL is here.)

I expected to be able to print this without supports based on my experience with PLA. I've just started working with PETG and it's proving to be ... temperamental.

My printer is a fairly new Prusa Mini+ that I've upgraded with a Bondtech IFS Extruder (with filament sensor). I've checked its calibration (it extrudes dead on 100mm by my calipers when given the command.)

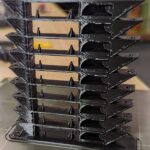

I've done temp tower which look like this:

The tower is, oddly, not showing the same chewed up behavior on overhangs. The filament is Prusament PETG Jet Black. I ran it through my Sunlu Filadryer S1 on at 50C for 6-8h (can't remember which) before printing.

If my only problem was the slight stringing I'm seeing, I'd be thrilled.

Any ideas how to fix this? I'm trying a print with supports now, but should I need them for this kind of print?

Best Answer by j.e.hahn:

And, I think, we can declare VICTORY!

Same part, roughly the same print settings (can't remember if previous attempt was 0.1 or 0.15, this is 0.15mm on the same 0.4mm nozzle)

So retraction distance and the like didn't end up being worth a damn. The thing that mattered above all else for stringing and blobbing was dry filament. I just ordered 2.5kg of desiccant and will be building a proper multi-spool dry box. (There's some slight stringing if you look carefully, but I don't even care, it's beautiful.)

On the chewed up edges, however, the realization came when I printed a couple functional parts later. All of the defects had only a little to do with the presence of overhangs and much more to do with the fact that they were in the first dozen or so layers. A part that had upper and lower 2mm pitch screw threads was perfect on the upper end and bound to the point of destruction on the lower threads. Looking at the parts from that batch, I noticed the entire lower area looked basically melted.

Prusaslicer's Prusament PETG profile for the Mini+ has the hotend go from 240 on the first layer to 250 on subsequent layers, and the bed go from 85C to 90C.

I switched to 240C on the hotend for the whole print, set fan to 75% full time, and set the bed to to 85C fixed.

Voila, solid consistent layers. I'm sure I could improve (and I'd still love suggestions!) But, I think I've got this problem nailed.

RE: Chewed up edges on PETG prints

Oh, I also did a 40mm vase mode cube. I had tweaked the flow rate to 95% based on some doc suggesting that would help my extrusion challenges. The resulting cube walls averaged 0.43mm ranging from 0.42mm to 0.44m across about 12 points. I can provide pictures, but I felt like it told me my problem wasn't extrusion flow rate.

RE: Chewed up edges on PETG prints

the lower section of curves tend to print badly because they are very shallow angles, one approach is to make the very bottom section into a 45 degree chamfer and then form the curve above that.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Chewed up edges on PETG prints

As much as I love PETG, in my hands it seems more prone to those overhang artifacts you're seeing than PLA. I usually just use support, and especially with PS 2.4, they come off like butter.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Chewed up edges on PETG prints

So I've got a part printing with supports. It's nearly done, but the edges still look really deformed. I've tried increasing the cooling to help with any bridging that's being done to build the edge. I'm suspicious it's basically getting overheated.

Would love some suggestions. I can, of course, go an edit the STL to make this a 45 degree angle and end my frustration. Am I tilting at windows trying to get a clean print on this part?

RE: Chewed up edges on PETG prints

And, here it is after printing with supports, after cleaning it up and getting the supports off.

I increased my retraction distance and speed and added retractions on each layer change. I increased fan to 100% and fan for bridging to 100%.

It's better, and this part is workable. But I still feel like I should be able to do better. Suggestions welcome.

RE:

And, I think, we can declare VICTORY!

Same part, roughly the same print settings (can't remember if previous attempt was 0.1 or 0.15, this is 0.15mm on the same 0.4mm nozzle)

So retraction distance and the like didn't end up being worth a damn. The thing that mattered above all else for stringing and blobbing was dry filament. I just ordered 2.5kg of desiccant and will be building a proper multi-spool dry box. (There's some slight stringing if you look carefully, but I don't even care, it's beautiful.)

On the chewed up edges, however, the realization came when I printed a couple functional parts later. All of the defects had only a little to do with the presence of overhangs and much more to do with the fact that they were in the first dozen or so layers. A part that had upper and lower 2mm pitch screw threads was perfect on the upper end and bound to the point of destruction on the lower threads. Looking at the parts from that batch, I noticed the entire lower area looked basically melted.

Prusaslicer's Prusament PETG profile for the Mini+ has the hotend go from 240 on the first layer to 250 on subsequent layers, and the bed go from 85C to 90C.

I switched to 240C on the hotend for the whole print, set fan to 75% full time, and set the bed to to 85C fixed.

Voila, solid consistent layers. I'm sure I could improve (and I'd still love suggestions!) But, I think I've got this problem nailed.

RE: Chewed up edges on PETG prints

As an addendum, my theory was right, but with longer prints with a lot of parts on the print bed, I am still seeing this behavior. I'm pretty sure the problem is that PETG being held close to the bed above 80C (which is supposedly the glass transition temperature of PETG) is causing it to sag and deform.

Interesting / unsurprisingly this effect is much worse on the textured sheet rather than on the PEI sheet.

Adding a raft gives similar results to the above, with the obvious drawbacks. So far 10 layers seems to be enough distance from the bed to not get substantial warping.