Periodically pop

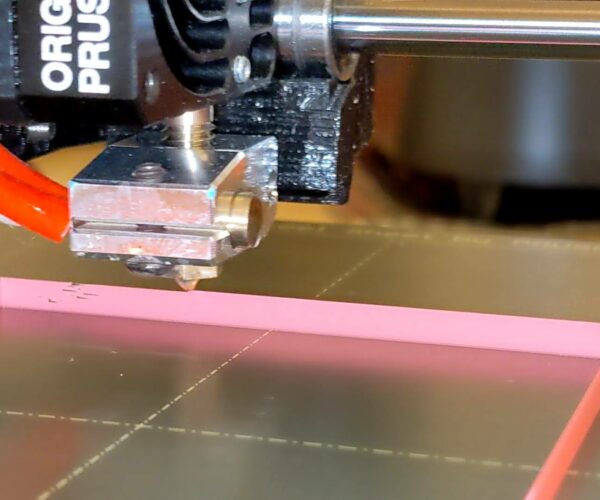

First of all, my printer works well with Prusament PLA. This week, I changed the filament to Kexcelled PLA and I found it print with holes on the thin walls. Originally I thought it is a typical underextrusion, however the fixes for underextrusion seem not work for me.

I found this issue when I were trying to calibrate with thin wall cube. This photo shows I enlarged the cube for observation.

What I observed

- For every layer, there will be one and just one such defect. It hold for 1.8cm cube and 7cm cube.

- Those detects happened almost at the nearby location as you can see from the above photo.

- This issue starts since the first layer. The location of first few layer may be different.

- For each detect, what happens

- First I can hear a pop sound.

- Immediately follows an underextrusion (the hole on the wall).

- If changed printing parameters (described below), the defect location may change. However, all layers changed together.

I have adjusted several configurations but no good results. What I did:

- This issue happens only with Kexcelled PLA k5 basic. This issue is gone if changed back to Prusament PLA. However, I still want to know how to print with other brands.

- Filament:

- I tried two rolls of Kexcelled (different colors) and have the same issue.

- Dried filament for 12 hours doesn't help.

- Fresh unboxed filament doesn't help.

- Filament spool is rolling smoothly.

- Tuning via knob:

- Temperature: From 180C to 220C don't help. 225C can make the hole smaller. The issue is gone with 230C. However, 230C is not useful due to lots of strings. I'm seeking other solutions.

- Speed: From 30% to 150% don't help.

- Flow factor: From 80% to 150% don't help. With 150%, the hole reduced and looks more like scars https://photos.app.goo.gl/qajxS11Jcf59TE1P7

- Print fan: from 0% to 100% doesn't help

- Device configurations:

- Tighten and loosen 90 degree the extrusion idler screw don't help.

- No clog of extruder gears.

- Tuning via PrusaSlicer

- Layer height: 0.15, 0.25 doesn't help.

- Extrusion multiplier: 1.0, 1.03, 1.07 doesn't help.

Anything else should I try?

RE: Something to try

I had (and still have) issues with surface blemishes accompanied by "pop" sounds as you describe on my MINI+. I have run systematic tests and found out that blemishes / pops occurred within a similar distance from the latest retraction on each layer (defects grouped in a small-ish area along the side of the print).

The only thing that corrected those was to reduce retraction substantially to 2.2mm (from 3.2), which results in a perfect surface. I'm not sure why that helps (maybe it has to do with pressure / air in the nozzle?) but it does.

I don't like my solution, though; it seems to indicate that somehow my printer has a defect / mis-calibration that prevents it from working as it should with the default PrusaSlicer settings for the MINI+ (and it could introduce more stringing and other side-effects, etc.). I'd love some input from others on what to do to fix the root cause instead of working around the effect!

Let me know if reducing retraction works around the issue for you too!

RE: reduce retraction works

fortinmike, your workaround works for me as well.

My experiments on retraction length:

- >=2.5mm always have this issue (10 times for 10 layers)

- 2.4mm not always (I forgot the ratio, maybe 50%?)

- 2.3mm and 2.2mm both happened once for 10 layers

- 2.1mm has no issue for 10 layers

- 1.5-2.0mm are all good as 2.1mm

I also tried to reduce retraction speed (with retraction length=3.2mm):

- >=35mm/s: the length of "hole" is roughly 2mm

- 30mm/s: roughly 1mm

- 20 and 25 mm/s: roughly 0.5mm

- I haven't tried other speed yet.

I feel your theory of pressure / air in the nozzle due to retraction sounds promising.

- if I increased the flow factor, the detect comes earlier. I guess the defect come out after a fixed amount of volume after retraction. (I am not so sure, I have tested two samples. Need more experiments)

- I printed the cubic wall with "spiral vase" mode, which has no retraction, and the surface is perfect. So the defect is highly corrected to the retraction event.

BTW, fortinmike, do you have the same issue with Prusament PLA?

Moisture?

I am very much beginner at this, so I may be off target here, but I thought popping was caused by moisture burning off as it passess through the hot end... Might be worth drying your filament before making a ton of adjustments, just in case?

RE: Moisture?

As I said in the first post, I have dried my filament for 12 hours and it didn't help. Moreover, if it is due to moisture, the defect location should be probably random.

oops!

Ahhh, you did.. apologies - I missed that.

As I said in the first post, I have dried my filament for 12 hours and it didn't help. Moreover, if it is due to moisture, the defect location should be probably random.

Linked to extruder issue?

No problem, @AndrewTerry! Thanks for trying to help. Moisture is indeed a leading cause of (more random) "pops" like this, but AFAIK when moisture is the issue it's often/always accompanied by excessive stringing and bad surface finish. For the record, I also tried drying my (brand new) filament before doing more tests and figuring out a workaround.

I'd love to know the real cause, though. Maybe it has to do with some slack in the extruder gears? I've been having this issue as well as some stringing I can't get rid of, even after adjusting temperature and retraction. Maybe there is a connection? I guess if the filament does not retract as well as it should it could cause this and require retraction to be toned down as I did.

I'd love for an expert to chip in here.

Popping on spiral vase mode

I have experienced this with spiral vase mode. I have a design with 3 part radial symmetry but would get the popping just on one spot. The overhang was too much and also there was a tight curve where the extruder would have to change directions. I got around it by improving the model, getting rid of the overhang and reducing the angle the extruder had to move. It never occurred to me that it was an air pressure issue but now that makes sense. I have attached a pic of the successful revision. I was getting the pop and the holes where the upper part of the lower petal meets the body of the vase before I redesigned it.

Mk3S+,SL1S

RE: More tests

- I printed the cubic wall with "spiral vase" mode, which has no retraction, and the surface is perfect. So the defect is highly corrected to the retraction event.

BTW, fortinmike, do you have the same issue with Prusament PLA?

There were no defects in spiral vase mode on my printer either, which tipped me off to retraction being a possible cause.

I tried a few different filaments (all from filaments.ca and all PLA, but different quality/composition). Print quality is otherwise great, so I'm not sure the filament itself is to blame. When you printed with Prusament, did you use the same filament preset as you used for the Kexcelled PLA, or did you switch presets? Logically I'd tend to use the Prusament PLA preset to print Prusament and the Generic PLA preset to print other filaments, but for testing it would be better to use the same preset for both.

I'll try with some Prusament and report back with my findings. It'd be great if you could also test the same things on your end. I think these would be relevant to test:

- Prusament with Prusament PLA preset

- Prusament with Generic PLA preset

- Other brand with Prusament PLA preset

- Other brand with Generic PLA preset

Then if there is a difference between profiles and not just filament brand we could compare the profiles to try to find the difference.

RE: More tests

I'll try with some Prusament and report back with my findings. It'd be great if you could also test the same things on your end. I think these would be relevant to test:

- Prusament with Prusament PLA preset

- Prusament with Generic PLA preset

- Other brand with Prusament PLA preset

- Other brand with Generic PLA preset

I tried three brands of filaments:

- Prusament PLA: I tried one color. It works well with any PLA preset.

- Kexcelled PLA: I tried two colors. Both have this issue, no matter using what PLA preset.

- ColorMatrix PLA (a local brand in Taiwan): I tried one color. With both preset, it has small pop sound nearby every layer. However, the defect is tiny and negligible. Actually, in this case, I won't call it defect --- I can only spot the unsmooth if I inspect the surface carefully with diagonal lighting.

Tests on my end

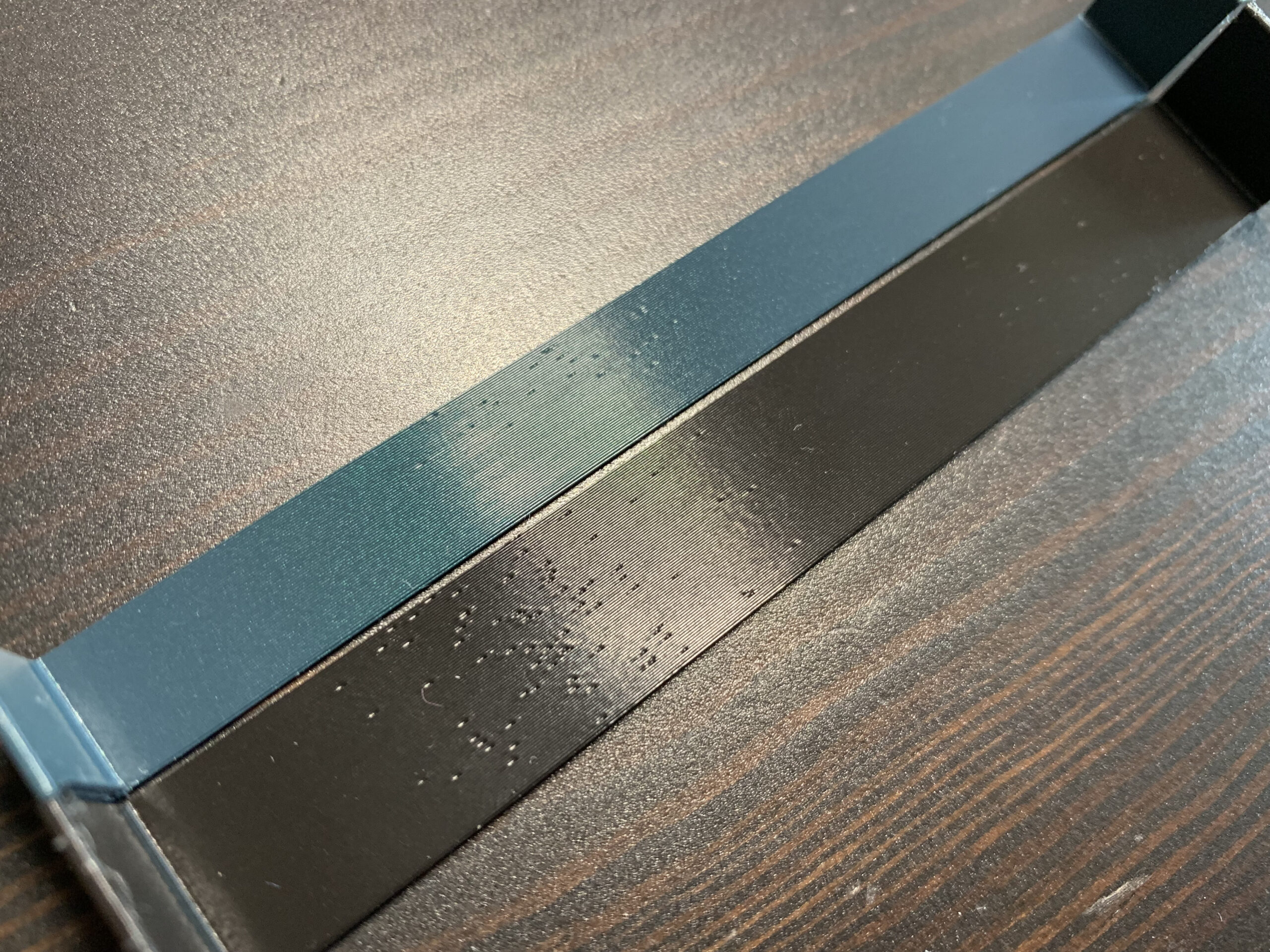

I tested the same profile with both my usual filament (Filaments.ca Canadian Maker Series 4043D) and the small Prusament PLA sample I had. Green one is Prusament. Unfortunately (or fortunately, for consistency!), both exhibit the same issue, albeit it's a bit less pronounced with the Prusament:

I'm thinking something might be wrong on my machine for it to exhibit this issue on Prusament also. I very recently performed a deep cleanup of the hotend and the extruder including PINDA adjustment and calibration, which helped a lot with some issues I had. These pops/zits still occur, though, and have been occurring since the first day I had my printer.

Anyone has some insight on that? We can't be the only two people having this issue...

Issue

I have had it with a few types of filament but especially with hydrated filament.

I tested the same profile with both my usual filament (Filaments.ca Canadian Maker Series 4043D) and the small Prusament PLA sample I had. Green one is Prusament. Unfortunately (or fortunately, for consistency!), both exhibit the same issue, albeit it's a bit less pronounced with the Prusament:

I'm thinking something might be wrong on my machine for it to exhibit this issue on Prusament also. I very recently performed a deep cleanup of the hotend and the extruder including PINDA adjustment and calibration, which helped a lot with some issues I had. These pops/zits still occur, though, and have been occurring since the first day I had my printer.

Anyone has some insight on that? We can't be the only two people having this issue...

--------------------

Chuck H

3D Printer Review Blog

RE: Don't think it's moisture in this case

The first thing I tried was to dry it, which didn’t help (the OP also tried it). I’ve observed this issue on all of the spools that I’ve tried (5-6 of them, mostly filaments.ca, but also some Prusament). I’ve been extra careful to keep my filament away from moisture and have stored them in sealed bags and containers with lots of desiccant from day one.

The fact that reducing retraction eliminates the issue also seems to point away from that possibility. Reducing retraction can have other side-effects, though, which is not ideal.

Could a defective / suboptimal extruder cause this? I’ve been hearing a clicking noise from my extruder for a while (see this post; it’s not a partial clog). Also check out my "theory" on pressure / air in the nozzle above.

I wonder if an extruder upgrade (e.g. Bondtech or clone) could help. Maybe the filament isn't getting retracted / pushed as well as it should? I did try to tighten the extruder idler for a better grip without any change in results, though. I’d like to find out what the actual cause is before trying to replace parts like that too. Plus I’d prefer keeping a stock machine and I’m intrigued what might be in store for the next official Prusa MINI upgrade. Seems like the extruder is currently one of the MINI's few weak points and could reasonably be the focus of the next model.