Over extruded PLA? what to check?

Hi,

I'm having trouble printing the famous articulated shark: https://www.printables.com/model/178032-articulated-shark

It seems the filament is sometimes too hot when leaving the nozzle in some layers, resulting in over extrusion. There are no problems with my functional prints in PC-Carbon (using a hardened steel nozzle) and PETG seems to print without problems too.

I'm printing with an enclosure, but with the doors open. I've set the idler tension as stated on the manual: flush to the extruder when filament is not loaded.

Prusament PLA

Prusa Mini

Default Prusament PLA profile (60C bed 210C nozzle)

0,4mm brass nozzle

Bondtech Heatbreak

Is there something else I can check?

Thanks for your help.

RE: Over extruded PLA? what to check?

Where is this "over extruded" portion situated on the print? Is this the peak?

--------------------

Chuck H

3D Printer Review Blog

RE: Over extruded PLA? what to check?

I find that it looks very similar to the print result in this post related to E3D revo hotend:

https://forum.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles/revo-micro-installation-on-my-mini/paged/7/

Together with the video from CNC Kitchen ( E3D Revo™ is great BUT has a dirty secret! (REVIEW) )

I believe the "Over extruded" problem is a result of small scale heat creep. It most likely occurred in:

a) a low flow rate condition and/or high retraction frequency layer

b) using E3D Revo or Bondtech heatbreak, which is a better alternative for replacing the original one

c) printing PLA

What actually happening are:

1) The very well performed heatbreak stopping the back flow of heat from nozzle.

2) A rapid temperature change over a very short distance (a few mm) within the nozzle (ref to CNC Kitchen video)

3) When layers are in low flow rate condition with high retraction frequency, a thin clog were formed near the rapid T changing region.

4) As Extruder keep feeding filament to the hotend with clog, Pressure inside the Hotend/Nozzle rise until the clog moved to the melting zone.

5) You can observe that the nozzle will start under extrusion in those layer for a while, the a lot of filament were push out from the nozzle and become the "over extruded" problem.

And I find some helpful tips in page 9 of the same post:

Hope it may help you too.

RE: Over extruded PLA? what to check?

yes, mostly on the lasts layers (on the fin)

Where is this "over extruded" portion situated on the print? Is this the peak?

RE:

I finally had time to do some test, but I couldn't come to a conclusion. This time is a small piece with a lot of retractions. Here are my observations:

After a cold pull the piece comes much cleaner, but the prints quickly start to look bad after 20 minutes of printing.

I tested the samples with the machine hot and cold, and it seems it doesn't make a big difference.

Changing the brass nozzle to a hardened steel one doesn't make a difference either.

After a PID tuning, the problem persists.

Now I'm going to test it again with other filaments, but as far as I remember, the issues appears only with PLA.

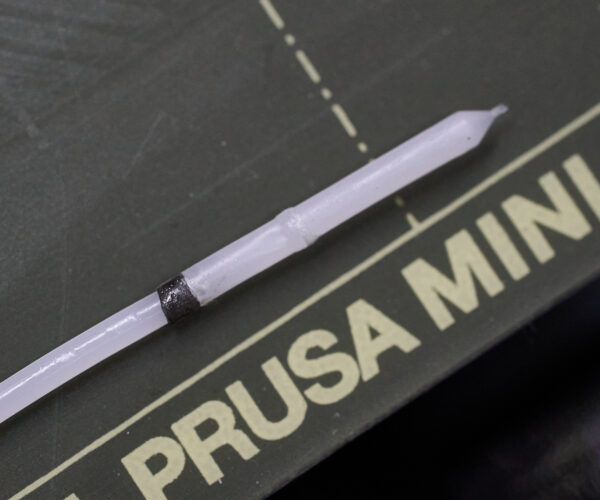

I made a macro picture of the cleaning filament after a cold pull. I'm not sure if I have seen something like this before on my machine, but it seems that there is a sign of a problem there.

On the top a piece after a cold pull and on the bottom in a later print.

RE: Over extruded PLA? what to check?

Did you ever fix this? and if so, what worked?

RE: Over extruded PLA? what to check?

I'm still struggling a bit. I replaced the heatbreak and the pla prints were noticeable better, but the problem appeared again after some weeks.

I'm guessing printing with PC carbon fiber deteriorates the heater block and that results in a bad sealing. There is some material spill on the top of the heater block sometimes and screwing the heatbreak and the nozzle is kind of difficult lately.

Next step is replacing the heater block for a plated copper one.