RE: Revo Micro installation on my Mini+

Sorry, just checked this myself... llama mini default fan speed is 38%; going to test this now.

void llama_apply_fan_settings() {

switch (_eeprom_llama_cache.HOTEND_FAN_SPEED) {

case eHOTEND_FAN_SPEED::HOTEND_FAN_SPEED_100:

hwio_fan_control_set_hotend_fan_speed_percent(100);

break;

case eHOTEND_FAN_SPEED::HOTEND_FAN_SPEED_90:

hwio_fan_control_set_hotend_fan_speed_percent(90);

break;

case eHOTEND_FAN_SPEED::HOTEND_FAN_SPEED_80:

hwio_fan_control_set_hotend_fan_speed_percent(80);

break;

case eHOTEND_FAN_SPEED::HOTEND_FAN_SPEED_70:

hwio_fan_control_set_hotend_fan_speed_percent(70);

break;

case eHOTEND_FAN_SPEED::HOTEND_FAN_SPEED_60:

hwio_fan_control_set_hotend_fan_speed_percent(60);

break;

case eHOTEND_FAN_SPEED::HOTEND_FAN_SPEED_50:

hwio_fan_control_set_hotend_fan_speed_percent(50);

break;

case eHOTEND_FAN_SPEED::HOTEND_FAN_SPEED_DEFAULT:

default:

hwio_fan_control_set_hotend_fan_speed_percent(38);

break;

}

}

RE: Revo Micro installation on my Mini+

OK right now I've got my PLA filaments working on the V2 mount, however it's not a solution for people running the stock prusa firmware as under the standard firmware the hotend fan runs at 50%, I have PLA printing nice again with the hotend fan set to 30% and I don't seem to be getting any issues with temperature swing on short extrusions and the benchys are printing fine again.

The benchy problems you were having (and I am still getting) looked like a cooling fan airflow issue on the small pillars, so I am scratching my head on why reducing the hot end fan speed helped. Do you have a theory as to why?

RE: Revo Micro installation on my Mini+

Unfortunately reducing the hotend fanspeed only seems to have helped for small prints like benchy's. I set off a bigger job tonight and cam back into the room to a spaghetti incident, comparing the failed parts to the slicer preview it seems the problem started once again with lots of small retractions on a spring bit it was printing.

As to my theory why reducing helps I'm not really sure, all I know is the V1 mount with the poor airflow and terrible fan didn't cause these issues for me at all on any material, but that fan is really bad and I don't feel comfortable with it on my machine so I tried the V2 which works perfect for ASA but cannot print PLA at all unless I drastically modify the filament profiles or reduce the hotend fan speed and even then it's failing some prints, and the cooler I set the hotend the worse the problem is.

I'm going to ignore this issue for tomorrow and come back with a fresh head but right now I really wish I didn't buy a revo.

RE: Revo Micro installation on my Mini+

Interestingly I’ve now tried both revo micro and six; same issue. So, I put my original V6 back on (not the stock hotend but the original V6 from a MK3 with modified parts; was in the mini working fine for 6 months) and I had the same issues. It failed at the same spot, admittedly not as bad but same issue. Everything is now back to pre revo upgrade and all settings and slicing back to stock with one exception; the Bowden tube. It’s the only part now replaced. I recut the end, chamfered it correctly with a jig and made sure it was snug into the v6 with no play at the collet clip. Benchy printed fine!!! My theory to test is either the cut on the end of the Bowden wasn’t flush and/or too much slop at the collet clip causing enough of a gap to feck up during periods of faster and quick succession retractions. Sad thing is that my printer is now working; first time working in over a week and I’m reluctant to take it apart again but I’d be focusing on the Bowden tube/collet clip combo when I do - it’s literally now the only easier thing I’ve not played with and tested. (I’ve tested hotend fan speeds, print fan speeds, flow, retractions length/speed/detractions etc, slicers, variable flow and print settings via super slicer, printed parts, et al).

I see videos and posts about people having great success with this new hotend which I’m invested in and want to work. I’ve a micro and six in a box, in the draw 😭

RE: Revo Micro installation on my Mini+

So you think the clip is warping the tube and the fast retraction areas are causing the errors? That's interesting, guess I'll print Lichtjaegers mount then.

Nice insights.

RE: Revo Micro installation on my Mini+

Just a theory. Having had the same issue on the v6 as the six and micro, the only difference being the Bowden tube it’s something to try. On the micro I had the collet clip pop off during a print once; there does seem to be more slop there. I need to print some jobs on my printer now and I’ll take take it apart and retest next week.

RE: Revo Micro installation on my Mini+

The bowden path being super smooth is something I've found critical with my Mini. If there is even a small amount of resistance between the extruder and the heatbreak I get issues, and if the PTFE tube in the heatbreak (this obviously doesn't apply to the revo) is moving around, or is compressed and deformed, or the ends are deformed from bad cutting... these make retractions cause all sort of problems for me.

RE: Revo Micro installation on my Mini+

Some progress made. Left is the V6 and right is the Micro. Only difference is I’m using a chamfered Bowden tube. Just a very small defect. Going to try different ID tubes and chamfered vs straight cut. Progress is being made though.

RE: Revo Micro installation on my Mini+

I've got @lichtjaegers V2 mount printed, just printing a ptfe chamfer jig now then I'll do the swap over, it'll be good to start getting the mini running at full pelt again.

RE: Revo Micro installation on my Mini+

Does it use the same 120 degree chamfer as the mini?

RE: Revo Micro installation on my Mini+

I've been following the thread as i was interested in the revo, mostly for the ease of swapping a set of nozzles per material (one for pla, another for petg, another asa etc).

As for the chamfer, would it benefit from an internal chamfer at the bottom to perhaps make a better seal with the heatbreak?

As regarding to licthens mount with the 25mm ptfe inside.

Prusa Mini+ kit. BondTech extruder. FW 5.1.2

Prusa MK3S+ kit. Stock. FW 3.11.0

Prusa MK3S+, used. Stock. FW 3.13.3

RE: Revo Micro installation on my Mini+

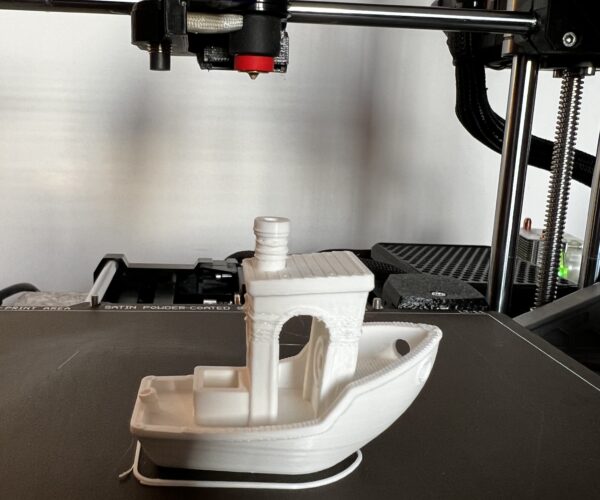

I’ve done so much testing and now not sure what to think. I’ve got an almost perfect Benchy using the revo six and a mount I used for my v6. I found the micro was too low and the print fan duct was cooling the heater. From this pic maybe it’s printing too hot at 210. The smoke stack shows this. Now that I can get a decent print going to play with the temps.

RE: Revo Micro installation on my Mini+

I'm having the exact same issue on my Revo Micro (but not my Revo Six)... ready to rip it out and go back to stock. 🙁

RE: Revo Micro installation on my Mini+

I’ve the same issue on both the micro and six on the prusa mini.

RE:

Interesting, my Revo Six is on my MK3S+ and it works well. The troubled Revo Micro is on my Mini+.

RE: Revo Micro installation on my Mini+

I take it back, there is no consistency. Take a look at this picture and tell me (ignoring the revo) what would you say is causing this issue?

The Teaching Tech channel suggests that the artefacts you are getting on the pillars are due to poor cooling.

It is exactly what I am getting - I posted earlier that I think the problem is caused by the parts being smaller than the nozzle area, and thus the stock cooling fan flow is diverted away from them by the nozzle. I am thus on the hunt for an alternative cooling duct arrangement that takes the Revo nozzle into account.

RE:

Thats a reasonable idea but on my benchy pillars at the minute I get worse errors on the fan side, also these errors all vanish on higher temp materials or even PLA that is stiffer than normal which leads me to think my issues are with the filament being fed into the hotend causing the inconsistent over and under extrusion on areas with lots of retractions. Unfortunately the spare ptfe I had to test this is no good as it's the wrong extremal diameter and the brass olives slip loose before the benchy completes.