Mini+ filament getting stuck, with pics (extruder flattening the filament)

I've had my Mini+ (plus a spool of PETG) for several weeks now. Unfortunately I've had to take apart the extruder to get mangled filament out about 8 times now. The first time was about a day into owning the printer (I don't remember what was printed) and the other times during printing a specific part, every time.

I'm not sure what the initial cause is, but here's the post mortem:

The end of the filament pulled from the hotend. After clearing the mangled filament from the printer, I can push this end manually into the hotend (with a heated nozzle) and the material goes through no problem. After reinstalling new filament the printer also works fine, so it doesn't seem like the nozzle itself is jammed.

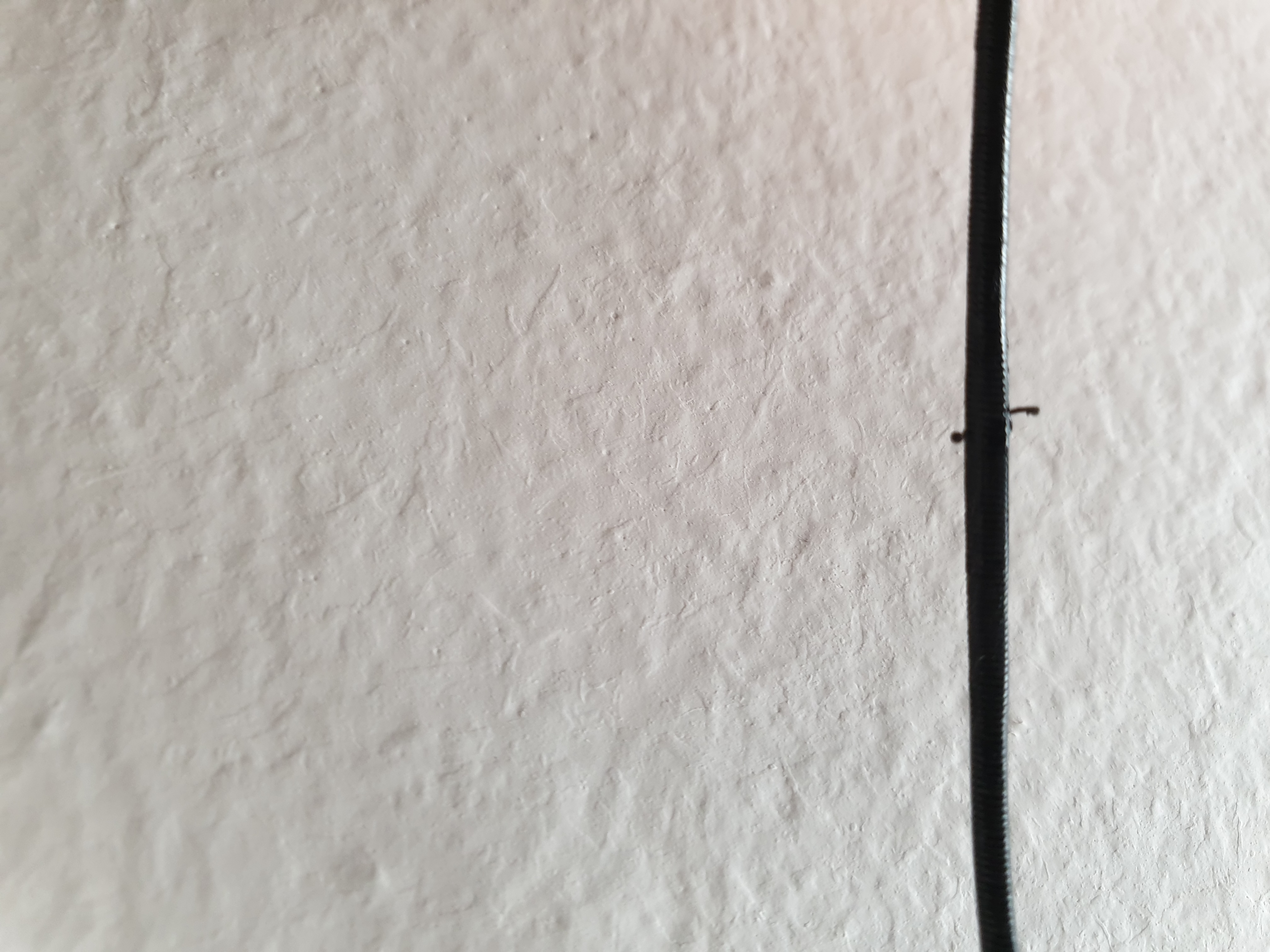

The filament inside the tube between the extruder and the hotend has several spots where it's flattened by the extruder. Since getting the filament out of the tube requires serious force, I believe this is where the filament gets stuck before it starts being chewed up inside the extruder.

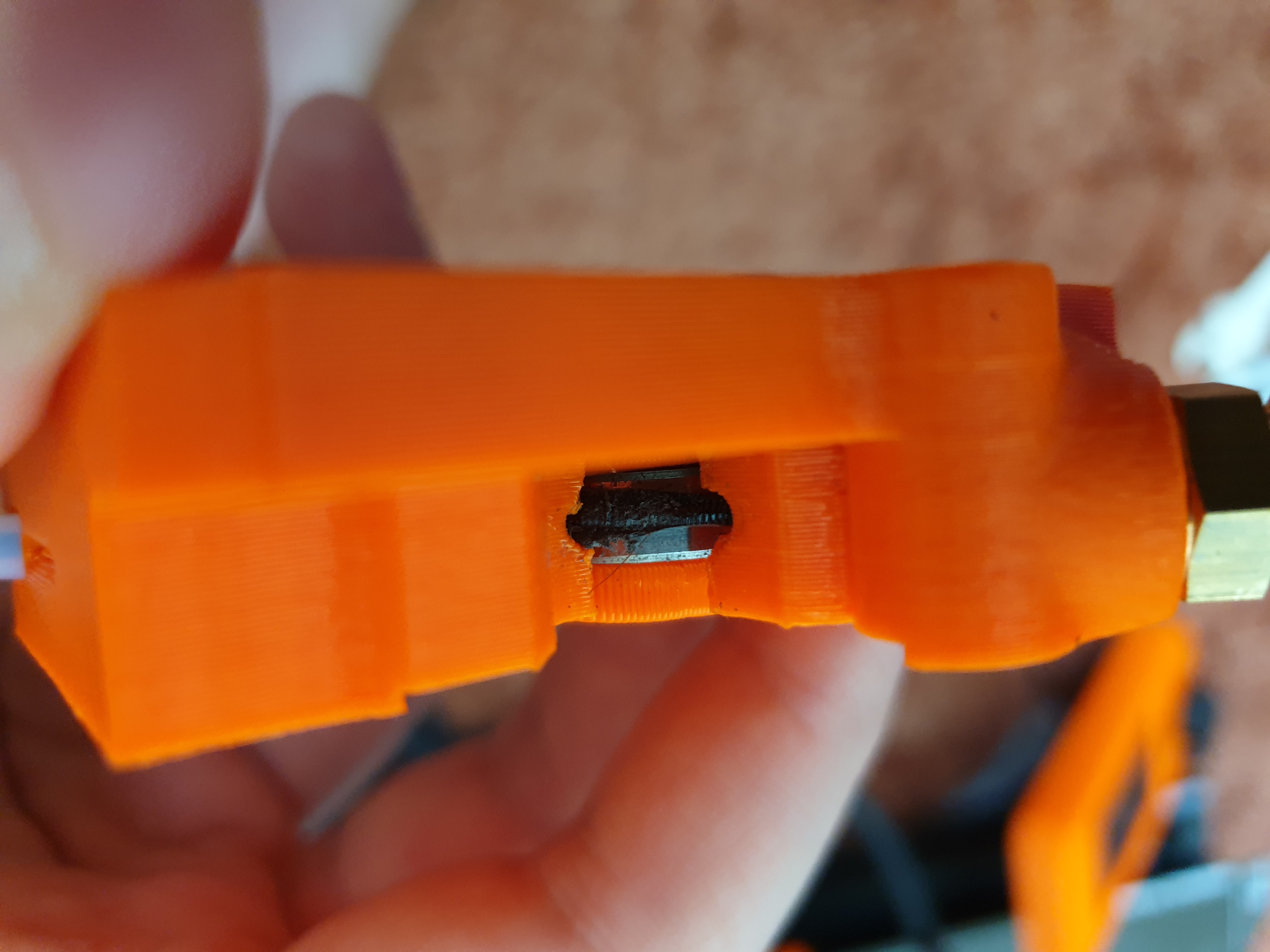

The mangled filament inside the extruder (requires disassembling the extruder every time).

This is what gets printed before the filament gets stuck. It's the catcher part of this:

Drill Guide and Dust Catcher

Originally I suspected the hotend to be the problem, so I tried, separetely, changing the nozzle temp from the default (250C -> 245C) and pushing the nozzle block deeper into the hotend assembly using the three small screws on the side -- neither helped.

The big part of the problem seems to be the flattened filament.

Thanks for any advice, I'm slowly starting to lose my mind here.

RE: Mini+ filament getting stuck, with pics (extruder flattening the filament)

Hi. New to this forum, and joining for the same issue.

I'm a professional mechanical engineer, with 20 years experience in the high-tech industry.

At home I have 5 Prusa MINI's, with over 5000 hours per printer for the oldest ones. I absolutely love them and I am very sympathetic towards Prusa, but this problem is getting too annoying. This is the only problem I have with my printers, but I have it on all 5.

I have found a few causes, and ways to (temporarily) solve it. (people please correct me if I have drawn the wrong conclusions):

The first is the small bowden tube in the printhead. If it is not properly compressed, a small pool of filament will gather, preventing the filament from being extruded properly. This in turn makes the extruder gear slip over the filament, which will wear a dent in the filament after which extrusion stops completely.

I have solved this many times by replacing the printhead PTFE tube, or just re-executing the tensioning procedure:

https://help.prusa3d.com/guide/how-to-replace-a-print-head-ptfe-tube-mini-mini_142572

Sometimes this works for 6 months, but sometimes I need to repeat it 2 weeks later, and I don't understand why.

The other issue seems to be environmental temperature. In the last few weeks I have seen a huge increase of this issue, on all my printers. I am now printing with the doors of my enclosures open, which seems to help a little. On two of my printers I have replaced the heatbreak with the one from Bondtech, which seems to improve it as well (these are the only two printers functioning today). https://www.bondtech.se/product/bondtech-heat-break-for-prusa-mini/. and it seems that Bondtech have designed this hot-end explicitly to improve on this problem.

Does anybody know why Prusa don't solve this problem themselves? I intend to expand my printing capacity, but I don't want to continue with this printer model if I can't get rid of this issue. Are other Prusa models free of this issue?

RE:

@Jack Ryder

The filament taken from the print nozzle looks good.

I suggest checking the filament path for obstacles:

- if the spool is spinning freely, no tangles

- if it is easy to push the filament without noticeable force from the spool through the filament sensor (this sometimes gets tight), to the extruder - fix any kinks in the tubes.

- check the spring tension in the extruder - maybe it needs to be increased so that extruder grabs filament better? Check if the filament has small but noticeable cuts from the extruder - if not then it starts to slip and with any filament movement obstacle it will start to grind into the filament.

- check for the obstacles between the exturder and hotend - the Bowden tubes, the small PTFE tube in the hotend if they are round, this can also cause blockage.

@Jaap

yes, generally that's why 3D print switched away from Bowden tubes to Direct Drive, and additionally if the short PTFE tube is not properly chamfered and compressed it gets problematic. Add to it the issue that sock heatbreak is known to have a heat creep - so the filament is melted too early and thus it starts to ooze to the sides or there are problems with extrusion. I don't know why Prusa did not address this in newer models of the Mini (may be ebcause of patent hell), but some companies noticed that and started to offer upgrade elements to solve that issue. Some people additionally use different fans to improve cooling of the heatbreak to fight of the heat creep, which is especially needed when having higher ambient temperatures. Look at Slice Engineering Prusa Mini Upgrade Kit, there is a good video about what happens.

I also recommend looking at https://help.prusa3d.com/guide/how-to-replace-a-hotend-ptfe-tube-mini-mini_119449

Those little metal rings on the tubes can move (Prusa call them olives), so this may be the reason why readjustment is needed, along with the typical mechanical issues such as things getting loose due to thermal expansion because of heating/cooling and movement.

Get Core One - right now this is the best of two - printer + enclosure. Or used MK4S if you want to save some money and you already have enclosures.

See my GitHub and printables.com for some 3d stuff that you may like.

RE: Mini+ filament getting stuck, with pics (extruder flattening the filament)

I've given up. TBH, I suggest you to do the same. This is in inherent flaw with this printer.

I've had my Mini+ (plus a spool of PETG) for several weeks now. Unfortunately I've had to take apart the extruder to get mangled filament out about 8 times now. The first time was about a day into owning the printer (I don't remember what was printed) and the other times during printing a specific part, every time.

I'm not sure what the initial cause is, but here's the post mortem:

The end of the filament pulled from the hotend. After clearing the mangled filament from the printer, I can push this end manually into the hotend (with a heated nozzle) and the material goes through no problem. After reinstalling new filament the printer also works fine, so it doesn't seem like the nozzle itself is jammed.

The filament inside the tube between the extruder and the hotend has several spots where it's flattened by the extruder. Since getting the filament out of the tube requires serious force, I believe this is where the filament gets stuck before it starts being chewed up inside the extruder.

The mangled filament inside the extruder (requires disassembling the extruder every time).

This is what gets printed before the filament gets stuck. It's the catcher part of this:

Drill Guide and Dust CatcherOriginally I suspected the hotend to be the problem, so I tried, separetely, changing the nozzle temp from the default (250C -> 245C) and pushing the nozzle block deeper into the hotend assembly using the three small screws on the side -- neither helped.

The big part of the problem seems to be the flattened filament.

Thanks for any advice, I'm slowly starting to lose my mind here.

RE: Mini+ filament getting stuck, with pics (extruder flattening the filament)

I've spent too much time on this issue. I'm done with it TBH.

RE: Mini+ filament getting stuck, with pics (extruder flattening the filament)

Same problem here, after 2500 hours of printing (the printer is 3,5 years old). I'm trying to solve the problems for months now. This is what I did already:

- used different spools of PLA (also Prusament)

- replaced the PTFE tube

- replaced the whole hotend (pre-assembled)

- thoroughly cleaned the gearbox

Nothing works. The problem keeps returning. Only installing a new assembled hotend worked for a very short time.

I was planning to buy a CORE One, but know I am having doubts. Prusa printers are much more expensive than other brands. In return you would expect a machine that lasts longer....