Just when you thought you mastered it

I'm not sure if this is a bug, or I am not understanding something, but I'll explain my dilemma and please tell me if I am wrong about this:

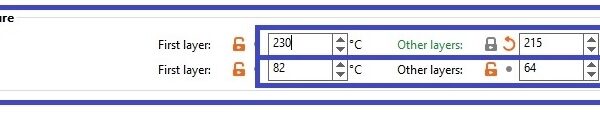

I have a design, its quite small but I can easily print 5 off at a time on my Mini plus. The face that contacts the bed must have a very smooth / polished like surface. To achieve this, I have set the 1st layer to the maximum bed temperature of 100degC then the other layers to 64degC. Likewise, I have set the nozzle temp for the 1st layer quite hot to 230degC this also helps to achieve to smooth surface on contact with the bed but again, subsequent layers do not so "other layers" I have set the layers to 215degC.

Here's the thing, when it finishes the 1st item and goes on to start the 2nd sequential item, it does show bed temperature changes 10odeg C and it does show nozzle temperature being changed to 240deg C but it doesn't wait for the bed temp and nozzle temp to be achieved before commencing, it just continues using the existing temperature before its achieved so not achieving the result I require.

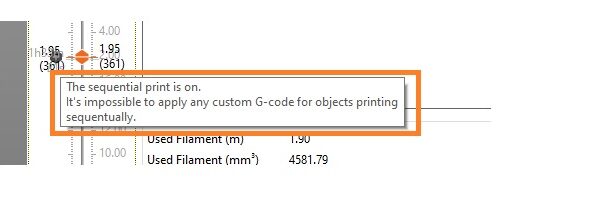

I know you can set g-code to wait for parameters to be achieved before commencing (like a temperature tower). The following image shows the response from PrusaSlicer

Any advise will be appreciated

Thanks in advance

Brian G

RE: Just when you thought you mastered it

...it doesn't wait for the bed temp and nozzle temp to be achieved before commencing, it just continues using the existing temperature...

-that's intended behavior. If printer would wait in the middle of job, then filament oozing would destroy the print.

Other than that, I think you're over-complicating with temperatures (for PLA I assume). Bed at 82°C for first layer to get more shiny surface? Well, whatever works for you...

[Mini+] [MK3S+BEAR]

RE: Just when you thought you mastered it

Hi

If you have ever printed a temperature tower, you include g-code to wait for temperature before commencing.

M140 = set bed temp

M109 = weight for temp

My point is, printing more than one item, PrusaSlicer doesn't allow you to do this. I'm wondering why?

Any comments

Thanks

Brian

RE: Just when you thought you mastered it

I have very popular temp tower on this site, and I don't wait for the temp change. Given the slight temp differences, it should be basically instantaneous so what's the point of waiting? But that's unrelated to your actual question.

You can still add custom gcode. Go to Printer Settings/Custom G-code and look for the Between objects G-Code section. I haven't tried it myself but that's where you can add a pause command. However, I would make sure you're not having the nozzle wait over the printed model (oozing) but move it away first, which may be tricky depending on the placement of the models.

Other than that, I think you're over-complicating with temperatures

I guess I'm with Bogdan on this. With appropriate Live Z, I have a hard time understanding the need for this.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Just when you thought you mastered it

Thank you for your very useful comments. Regarding waiting for temp, ordinarily, and I share your thoughts about the temp tower with no point in waiting for the change in temp before proceeding but on this particular part it is essential. Its a small component so everything happens quickly and the layer must be at a specific temperature, if I don't wait for temp to be achieved, the temp I want will be on a layer that doesn't matter.