Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

Hey,

I'm having some issues with my Mini: After a few (successful) prints, I had a failing print with PETG (clogged nozzle). Didn't think alot about it, heated, unclogged, done.

But now I've head two more clogged nozzles / hotends during prints with PTA and I noticed some issues: The prints start out fine (and manual extrusion works as well), but after a minute the nozzle clogs. I wanted to make sure that nothing is in the hotend like leftover PETG (which could lead to issues), so I went for the the "Atomic Method" which I used successfully for years on my Anycubic and i3 MK3S.

Since the extruder gear rubbed through the filament on the Jam I had already removed the bowden tube, so I've heated up the hotend to 260 (to get all PETG leftovers), set it to cooldown and continued to push through PLA manually. So from my MK3S and Anycubics, I'm used to it that I can push through PLA until the temperature reads ~175, then it becomes rather slow. On the Mini however, it got hard to push at 190°C already. For me this means that there is a "disconnect" between the actual nozzle temperature and the read-out temperature, which can lead to the clogged nozzle.

The pullout also looks wrong: Usually by this method, I had nice cones which had only a very small ridge where it goes from "never been molten filament" to "actual hot part of hotend" (so within the heatbreak). But on this pull it seems that the heatbreak did not produce this "clean cut" in temperature, so the filament streched a lot.

Photos from a failed print and the pullout leftovers https://imgur.com/a/sCa1AtO

So unless sb suggest something else: Are there official "service instructions" for the new mini hotend? Like disassembling it properly and proper reassembly?

Best regards, Olli

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

same goes for me: didn't think too much at first failed print, but it seems to repeat; after the first clean out I could do another nice print, then a fail; subsequently no good print to be had... actually quite disappointing!

I noticed a strange noise accompaning the extruder action - as if the extruder gear wasn't working correctly?

best regards Christoph

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

@christoph-r6

Yeah, thats the gear skipping after the nozzle clogs.

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

Also check the thread here:

https://forum.prusa3d.com/forum/hardware-firmware-and-software-help/what-is-a-good-tension-for-the-prusa-mini-feeder/#post-198090

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

hi I have had similar problems, after i have sliced a model with the temp set to 215 in slicer when i load it to print the hot end temp shows as 170 degrees so i have had to turn the hot end temp up, i was still getting layers that didn't fuse together so i have set the hot end to 235 degrees which seems to work, but is it a faulty hot end or buggy firmware?

I haven't had any more clogged nozzles when running prints at this high temp and fitting a silicon sock.

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

Hi everybody,

Same here at my prusa mini.

I can't print any PLA with its normal temperature. This happened suddenly.

The first two weeks, there wasn't any problems. But during a new print I got a jam in the hot end. The extruder started clicking.

After this I wasn't able to print anything with its normal temperature. PLA could be printed with 260 or 250 degree.

Because of this I replaced the thermistor with a new one. There was no change...

Can anyone check the temperature of the nozzle and compare it with the temperature measured with the mini?

I think there is a bug in the software after reading all your comments.

Greetings

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

First thing to check is the hotend, the heatbreak may need to be moved up inside the heat sink. See https://forum.prusa3d.com/forum/general-discussion-announcements-and-releases/prusa-mini-filament-frequently-jams-after-about-2-hours-of-printing/

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

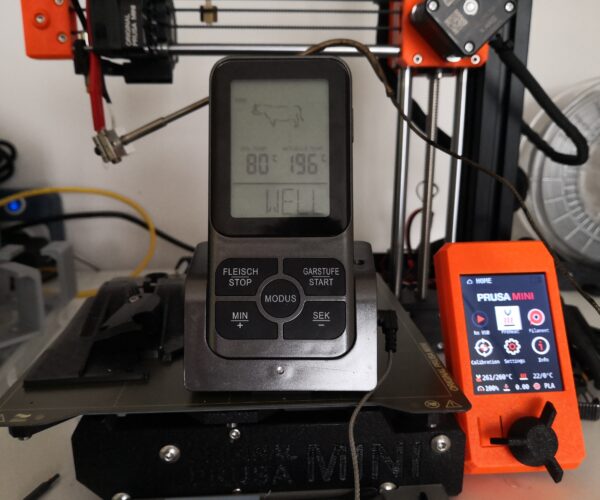

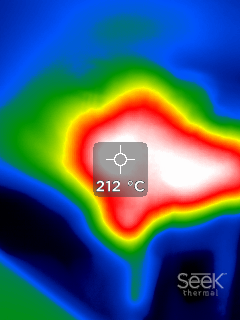

Did a test today. I tried to measure the temperature in the hotend.

I was using a meat thermometer. I set the nozzle temperature to 260 degree and only got 200 at nozzle. The meats my experience with the behavior of filament.

Just wrote to the support and waiting for answer.

Greetings

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

I had a similar issue, but in reverse: My Mini was printing fine for the first week and all of a sudden would string like mad.

Turns out: The thermistor at the hotend hat a loose contact and depending on how I would bend it's wire it would change about 5° at room temperature and up to 15° at 210°C (watch your fingers if you try that to not get burned on the hotend!). I then directly measured the hotend which was dialed in to 210°C and got 228° which explained the stringing.

I ended up replacing the thermistor (the Mini is using a "100K thermistor - ATC Semitec 104GT-2/104NT-4-R025H42G (Used in ParCan & J-Head) (4.7k pullup)" compatible one, see https://github.com/prusa3d/Prusa-Firmware-Buddy/blob/master/include/marlin/Configuration_A3ides_2209_MINI.h#L312 ), dialed in the temperatures and can now print again as normal.

I also routed the thermistor wire under the minda probe brace as I think the space between the cooling fan and the minda probe brace where the hotend heating wires go is too small and only having 2 wires there reliefs a bit of pressure/strain.

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

I confirm too that the Mini is reading wrong temperatures. Even after fixing the hotend I constantly need to print PLA at 10 / 12 degrees higher temperature.

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

Dear Mini-friends,

the same thermal aberrations are visible at my hotend as well...

Those problems seem to be one part of the annoying underextrusion-phenomenom that seems to be wide-spread within our community.

Hopefully the devs will get rid of this whole complex soon!

Take care

Chris

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

I have done all the "fixes" I found so far (shifting the heatbreak up, replacing the PTFE, adjusting extruder tension, removing the filament sensor) and still have to set the temperature 15-20 degrees hot to get anything to print (can only print PLA at 240C or higher). However, I put a probe on the extruder (thermocouple type that came with my Fluke meter) along with some heatsink compound to ensure good transfer and discovered that it appears to be correct measured at the thermocouple and at the nozzle. Within 2-3 degrees of the setpoint. Don't know what else to try. Mini worked great for about the first 100 hours.

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

I'm having very similar issues as the OP. To recap:

- Got about 5-6 good prints with no issues (other than inconsistent first-layer squish, but that's a different topic)

- Suddenly had a failure that looked like a jam (filament stopped flowing and drive gear chewed through the filament)

- Cleaned everything and manually fed a bunch of PLA through the nozzle, but subsequent prints still fail at normal PLA temps

- Tried higher temps but results are varied

- Measured the hotend temp with a thermocouple on my DMM and got readings of 15-20 below setpoint

- Checked the hotend "distance from heat sink" and PTFE tube length. Both are good.

One observation that I have not seen mentioned yet was the behavior of filament when manually feeding through the nozzle. I preheated to 215 and fed PLA through the hotend and it seemed to be flowing fine, but suddenly I would encounter a lot of resistance, to the point where I could not feed filament through. After a few seconds, the filament would release and start flowing again. I can imagine that if this happened during a print, it would cause the drive gear to click or grind filament, which is what I am seeing happen at normal temps. When I print at a slightly higher temp I can see a visual of the "choke and release" behavior when the printer transitions from slow perimeters to faster infill (the infill will look under extruded for a few seconds and then there will be a massive release of filament and then normal printing for the rest of the layer.)

Clearly something is going wrong with the temperature of the hotend. I contacted support a few weeks ago but they simply replied with how to clear a jam and check the PTFE tube length. Like many of you, I believe the issue is caused by improper temperature of the hot end, and has the smell of the software bug.

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

I had all those symptoms too.

The symptoms you describe are exactly those of the PTFE tube allowing a bulge in the filament which jams. The officially recommended distance from heatsink is WRONG. At least, it is not sufficient. You need to move the heatbreak all the way up, AND ensure that the PTFE is long enough, otherwise you will still get jams.

Possibly, there may also be an issue with hotend temperature, I haven't seen any reliable evidence. It's more likely to be a faulty thermistor than a software issue anyway. Increasing the temp will help a bit, because it helps melt the filament jammed in the heatbreak, but it's a workaround not a fix.

This Mini hotend issue is going to be a continuous problem with the Mini, probably until the design is changed.

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

AND ensure that the PTFE is long enough, otherwise you will still get jams.

This. Mine was a smidge short even after pushing the heat block up all the way into the heatsink. Explains why it worked for a while then quit - it worked until the tube shifted up. I think the problem is exacerbated by Prusa's decision to omit the heat break from the design. I guess it reduces manufacturing costs but makes it challenging to prevent molten filament working too far up the feed tube.

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

I'm having a very different problem (i3 mk3s, 1 year old). The hot end temperature is drifting all over the place - sometimes, the print won't even start. For example, if the temperature is supposed to be (hot / bed) 230 / 60, both start to heat up. After a while, the hot end temperature starts to go crazy, such as "225, 226, 227, 260, 259, 258, 214, 230, 214" etc. Jumps are sometimes 20 degrees or more just from one reading to the next. If the print does manage to start, the hot end temperature seems to be far too high and is resulting in horrendous stringing. The printer has been doing great for a year, this is a new issue. I've checked the thermocouple wiring, tried removing the silicone hot end boot (I've been using one of them for almost the entire time I've had the printer - really cuts down the tendency to clump). The slicer software and firmware are both up to date. Anybody have a suggestion of what to try next?

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

@john-d61

You've posted to a thread in the Mini section of the forum, you'll probably find more people can help if you post in the Mk3 section of the forum.

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

Nevertheless, his issue seems easy to diagnose at first glance: That sounds like a loose contact in the thermistor cable. So if you write that you checked your thermocouple wiring (which I assume you mean your thermistor), what did you do exactly and did you just try another probe incl cable all together?

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

I wanted to chime in again, since at the moment I‘m in a state of hassle-free printing...

After the change of the PTFE-tube and readjusting the distances just seemed to be of temporary solution I went for the complete exchange of problematic structures...

I exchanged the stained heat-block with thermistor, changed the heatbreak for the Bondtech one and exchanged the extruder in favor of a Bondtech dual gear as well.

At least I can’t really say what helped, but now I get my print-jobs done and don’t have to fear spontaneous underextrusion.

Like I said in another post - I‘m a bit mad about the flawed initial design and the substantial amount of money for the upgrades (more than a quarter of the initial price), but now it’s working as intended...

Cheers Chris

RE: Hotend temperature Issues (clogging, temperature seems to be lower than read). Assembly instructions for hotend?

@maze-mdk

Your comment made the difference! I checked the thermistor and ended up disassembling part of the hot end. Some filament had gotten up around the thermistor cables and jammed in there, probably due to the silicone bootie causing some backup. After a thorough but careful cleaning last night, the temperature is now holding steady again, the bootie is off for now, and I was able to do a fairly intricate print with almost no stringing. Thank you! And the grandkids, who will be here in a while to help me assemble their new little toys will thank you too. They love watching the printer, and with the pre-print last night we'll have toys to play with soon.