horizontal lines on walls

Hi all,

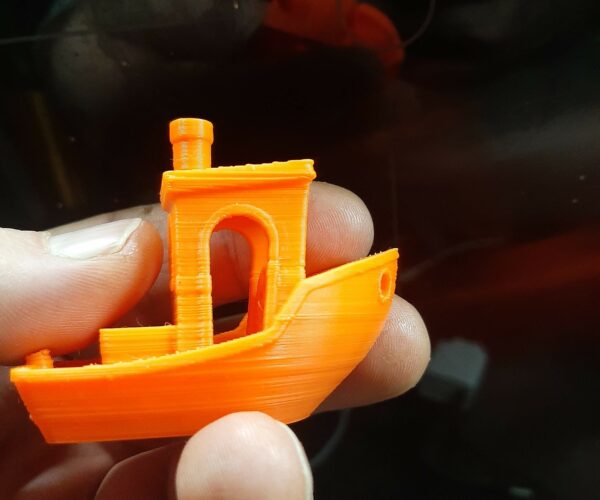

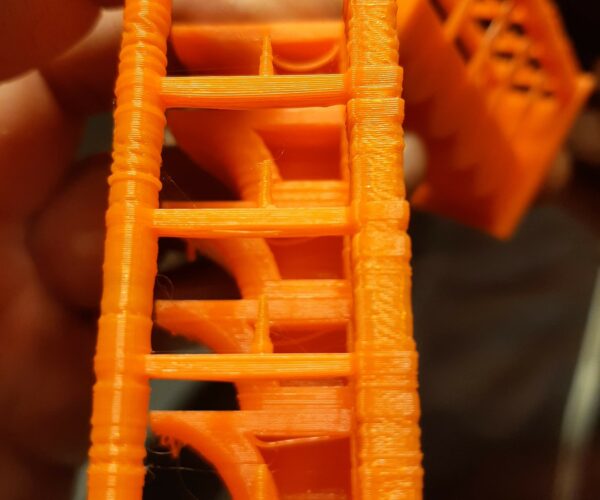

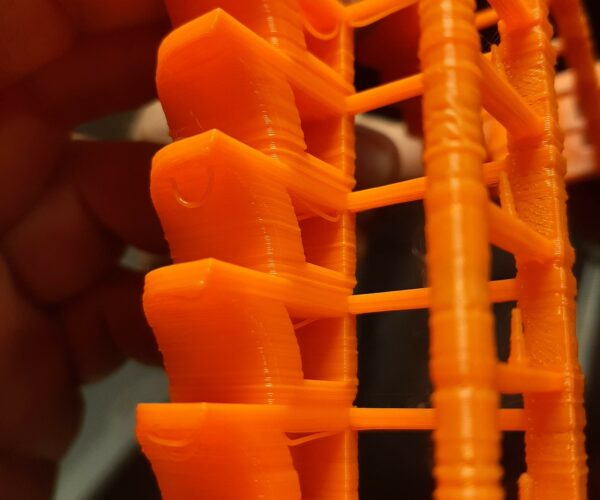

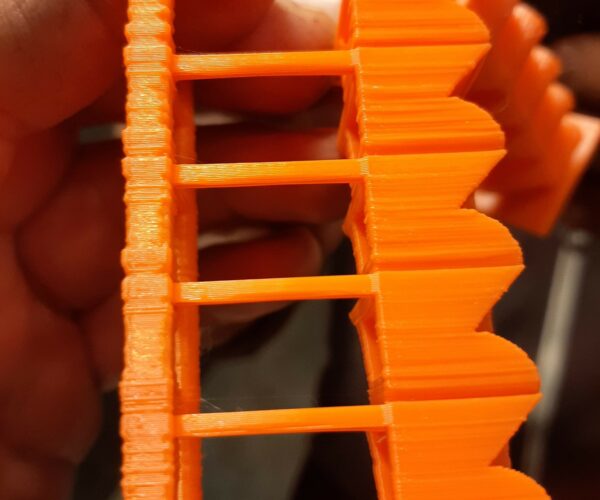

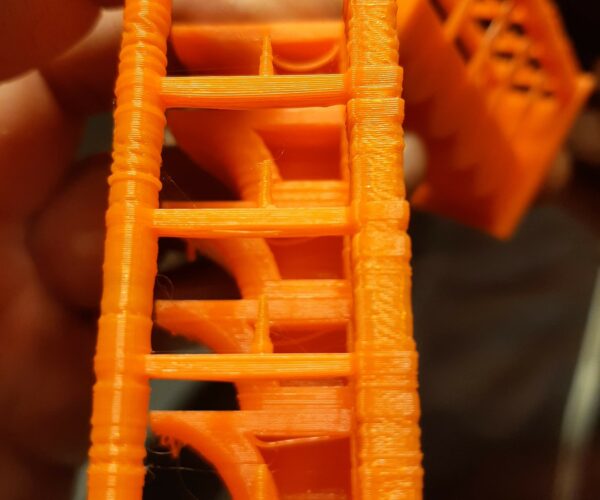

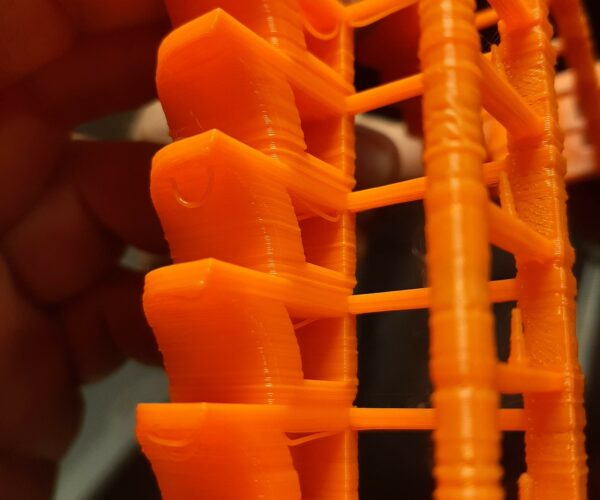

I don't know how to explain the problem - so I have a few pics:

Overall print quality is ok, but walls are bad.

Interesting to me is that when printing in Vase mode, walls are perfect.

Belts are tight, rods oiled...

Upgrades: Bondtech extruder and heatbrake and NozzleX 0.4mm. Prints in pictures are Prusament PLA .2 Quality

Any ideas?

Best Answer by HerGiz:

Update - I tried Micro Swiss .4 nozzle (brass and coated with TwinClad XT). It is abrasion resistant (they say and I hope :)).

First I tried with BondTech heatbrake. Again tried to tune it, but (Prusament PLA dried):

Then I went back to stock heatbrake, kept Micro Swiss nozzle, repeated PID, Linear advance (now is 0.34), retraction 2mm, and some other minor tweaks, and this is the result:

There are few minuscule error in print, but it is perfect. I don't know which temperature to pick from the tower, they are all ok, even pins are hard to brake. I also printed tolerance test ( https://www.prusaprinters.org/prints/1707-tolerance-coin) and it passed all of them.

This is now definitely end of this story. Micro Swiss nozzle for glow in the dark and original heatbrake. BondTech heatbrake and/or Nozzle X (tried all combinations) does not print PLA on Prusa Mini (at least mine).

Concerning clogging (which was the reason for upgrade), I will stock up with PTFE tubes, will try Capricorn ptfe.

Thank all !

It looks like something is hampering axis movement.

First, with the power off, move each axis by hand; is it smooth? Does the resistance stay the same over the whole range?

Check the smooth rods are not damaged/scratched. Check the idler pulley is not clogged, out of line, or damaged (loosen the belt and try turning it with your fingertip, is it smooth?)

With the belt loose try turning the stepper motor by hand; is it smooth?

Retighten the belt until it just begins to make a low musical note when plucked...

Make your next print this:

https://www.prusaprinters.org/prints/46639-tension-meter-for-the-gt2-belts-of-i3-mk3s-or-prus

It MUST be printed in Prusament PETG or the spring tension will be wrong.

Let us know how you get on.

Cheerio,

RE: horizontal lines on walls

Check the grub screw for the drive gear on the Extruder.

...Doug

RE: horizontal lines on walls

I didn't have time to fully try yout solution, hopfully tonight.

I did disasemble y axes and it is perfectly ok. X is next and then checking belt tentiom. Will report

RE: horizontal lines on walls

To me it also looks like extrusions isue, but, i disesembled bondtek extruder and retightned everything. It is not that 🙁

I think I will try stock extruder, just to check sanity.

RE: horizontal lines on walls

Y and X components reassembled, re-tightened, oiled... Nothing was lose, belts are ok... No isues.

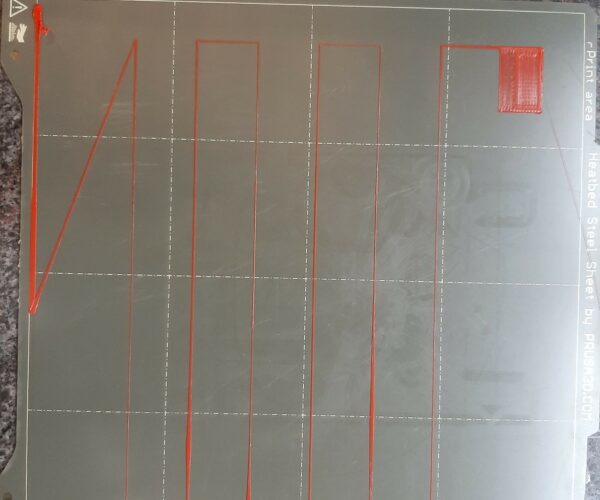

While I was redoing Live Z i noticed this:

I did not touch height during entire process. This is obviously extrusion issue.

But yesterday I reassembled bondtech extruder and everything is as it should be. There is no clicking...

I did upgrade to bondtech because stock started to click on every print, so I replaced heatbrake and extruder to Bondtech and nozzle to Nozzle X .4 original E3D because I regularly interchange glow in the dark and normal PLA.

I'm am running out of ideas.

RE:

I had a similar problem with my MINI+, in my case I have solved it in this way:

- I checked the extruder and removed some filaments inside (but this was not the problem)

- I changed the nozzle (previously I used the E3D Nozzle X) (but this was not the problem)

- I did some cold pull (but this was not the problem)

and finally i followed this procedure

https://help.prusa3d.com/en/article/clogged-nozzle-hotend-mini-mini_112011

The problem was an hotend clogged... after a cold pull (without the PTFE tube installed) the printer is back to print perfectly.

RE: horizontal lines on walls

Interesting live-z pics!.

- Extruder shaft bent?

- Gear drilled off-center?

- Teeth missing from gear?

RE: horizontal lines on walls

Currently I'm reading this thread:

I have few ideas to test. Will post updates

@lul3d-com I have checked extruder. It is dual gear, so little of-center should be ok. On eye everything looks ok.

Your first layer Z is now too low, too squished. I suspect you were still modifying the level as the final rectangle was starting.

At the end of the calibration you are aiming to print a single layer *sheet*. It should be possible to peel it off in one and fold it without the threads seperating. If it breaks into lines it is too high, not squished enough. If it is a single sheet but with wavy lines or drag marks on it you are too low.

For most people it pays to use 7x7 mesh bed levelling.

Revisit the calibration then make another test print, let's see if your efforts have changed anything.

Cheerio,

RE: horizontal lines on walls

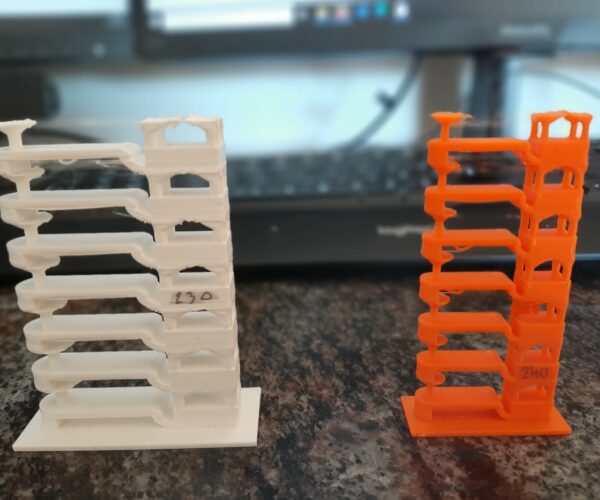

From my experience, this is because the filament is moist. And you have to dry the filament. I have this problem long time ago. And after dried my filament, the layer lines is gone. Here is my sample image the left is moist filament, the right side is after drying the filament. Both use same filament roll, same gcode, same printer (without any mod or changing belt tension, gear, bearing, etc.)

RE: horizontal lines on walls

So. Did few more tests, slicer tweeks, checked tensions and what not. No improvement.

Yesterday I retutned original heatbrake and extruder started clicking, but primts are back to normal.

In the thread i posted before, they have come to conclusion that Bondtech heatbrake performs to good, and there is not enough termal mass for PLA (especialy Prusament at which the problem is most visible).

PETG works perfectly. Most would say (as Bondtech do) dont use nozzleX, but I have printer for continuous glow in the dark and other PLA's.

I will try drying my PLA, and in the mean time I am going to search for diferrent hot end.

I hate Marketing, that is my conclusion - to Prusa and to BondTek (I shoud have bought Ender for the frame, and replaced everything, it would be cheaper)...

Will report on my furher findings

RE: horizontal lines on walls

So... I tried stock heatbrake with Nozzle X. Better, usable, but far from perfect. I don't know how much is visible on the photo, but temp tower for PLA from 240°C downwards at steps of 5 and at every step it looks basically the same (white is azure film, orange is Prusament Orange (dried)):

Then I went for BontdTech heatbrake and stock brass nozzle. Disaster - failed to print due to clogging and scipping. Side comparison is with stock heatbrake and nozzle configuration printed the same day with same filament and same Gcode (except PID values):

My final conclusions at which I think this thread can come to close.

Prusa Mini is not able to print PLA if modifications are done on hot end assembly. Abrasive PLA (glow in the dark) can not be printed on Prusa Mini.

As the temperatures goes up, PETG (print perfect with upgrades) and presumably others (not tested) work ok / need upgrades like BondTech heatbrake to work properly due to heat creep to original heatbrake and PTFE shrinkage. Excellent, but you LOSE ability to print PLA.

I need to print PLA and abrasive PLA, and will have to by another printer or replace hotend entirely. Revo? Moscito? Dragon???

BondTech extruder helps, and is a must after 2-3 months.

I only wish I have found this info before buying upgrades. Hope this help to somebody else.

I do think Prusa Mini is excellent purchase and worth the money, but the info on this would be appreciated.

Read this thread for in depth reasons, testings and more on the same subject:

Thanks all for suggestions and ideas 🙂

RE: horizontal lines on walls

I understand why you have come to those conclusions but I don't think they're generally valid.

Prusa Mini is not able to print PLA if modifications are done on hot end assembly

I don't know from personal experience (never had a need for the Bondtech heatbreak) but given that there seem to be a good number of users with the Bondtech, I would expect to hear a lot more noise about it if it were indeed true.

Abrasive PLA (glow in the dark) can not be printed on Prusa Mini.

I've printed a fair bit of GITD on the Mini, with the stock brass nozzle and with hardened steel. No issues. Likewise, I've printed wood and steel filled PLA no problem.

need upgrades like BondTech heatbrake to work properly due to heat creep to original heatbrake and PTFE shrinkage

Maybe, maybe not. While there are certainly plenty of reports of people seeing PTFE shrinkage, I've not experienced it myself on two Minis over more than a year of printing.

My point is, I totally see why in your specific situation you have come to those conclusions but I just wanted to share my own experience as a counterpoint to illustrate that they may not be universally true.

BondTech extruder helps, and is a must after 2-3 months.

Now with this statement I totally agree. Maybe "must" is putting it a bit strongly but it's the only Mini upgrade I wholeheartedly recommend. I haven't had to adjust the idler once and didn't have a single clog since installing the extruder.

Dragon

I've been running Dragons (standard flow) on all my Minis and Mk3S+s now for a few months and I couldn't be happier. I should say that I don't see any appreciable difference in print quality. Maybe you can push the throughput up a bit but I haven't seen a need to try it. The main selling point for me was the one-handed nozzle replacement as I constantly move between nozzles on my machines. Gone are the days of accidentally breaking the thermistor cable...

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: horizontal lines on walls

@fuchsr Respect.

I know that this are my conclusions based upon my experience. Everybody has their own need and use case. Mine is PLA and qlow int the dark PLA, and 3 months in, 3 nozzles, heatbrake and extruder upgrades have not made it possible. Changing nozzle on mini is no small feat, and every time I think i will break something.

I still love my mini, but I need hotend upgrade. Now I am in dilemma, waiting for Revo, or going for Dragon? I am still exploring... Or maybe Ender 3 (or another mini) for glow in the dark. Dilemmas 🙁

But I still hate marketing! 🙂

RE: horizontal lines on walls

Just a quick question. Which firmware are you running and did you change the esteps when you changed to the bondtech extruder?

My prints looked similar because I forgot to change the esteps. In the new firmware you can easily change them in a hidden menu. After that, everything went smoothly.

Maybe you already did do that, I just quick read everything and not in complete detail :/ But that is something I would check again 🙂

RE: horizontal lines on walls

Did that too. I was fortunate that new firmware came out just when I did the upgrade.

Problem is thermal mass. PLA is a bit dense, and with bondtech heatbrake (and especially with nozzle X) there is no time for proper PLA flow. Others have found that Prusament PLA is most affected.

Due to insufficient melting, there is small clog, and it is visible as little under extruded. Second later the clog is melted and the result is over extrusion - effect is uneven walls.

I just got Micro Swiss plated wear resistant nozzle. I will try with that and see the performance. Next change will be hotend, either Dragon or Mosquito hotend as I do need wear resistant nozzle, and on stock prusa mini it is not easy not healthy to change nozzle every day.

RE: horizontal lines on walls

Update - I tried Micro Swiss .4 nozzle (brass and coated with TwinClad XT). It is abrasion resistant (they say and I hope :)).

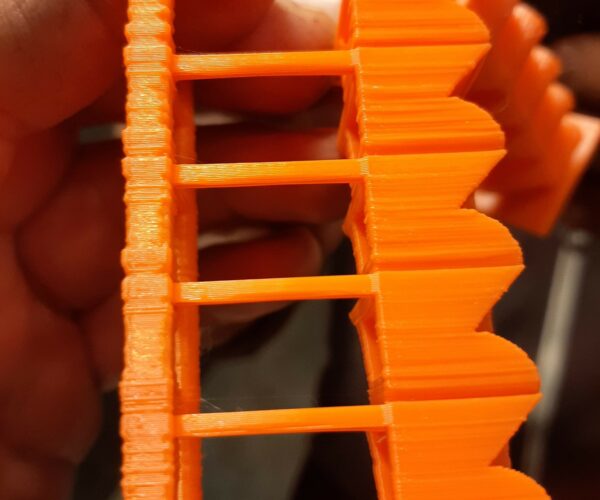

First I tried with BondTech heatbrake. Again tried to tune it, but (Prusament PLA dried):

Then I went back to stock heatbrake, kept Micro Swiss nozzle, repeated PID, Linear advance (now is 0.34), retraction 2mm, and some other minor tweaks, and this is the result:

There are few minuscule error in print, but it is perfect. I don't know which temperature to pick from the tower, they are all ok, even pins are hard to brake. I also printed tolerance test ( https://www.prusaprinters.org/prints/1707-tolerance-coin) and it passed all of them.

This is now definitely end of this story. Micro Swiss nozzle for glow in the dark and original heatbrake. BondTech heatbrake and/or Nozzle X (tried all combinations) does not print PLA on Prusa Mini (at least mine).

Concerning clogging (which was the reason for upgrade), I will stock up with PTFE tubes, will try Capricorn ptfe.

Thank all !

RE: horizontal lines on walls

Remember to re do the Live Adjust Z everytime you move/change something before printing!