Filament stuck, nozzle dirty, PTFE tube broke...

Hi,

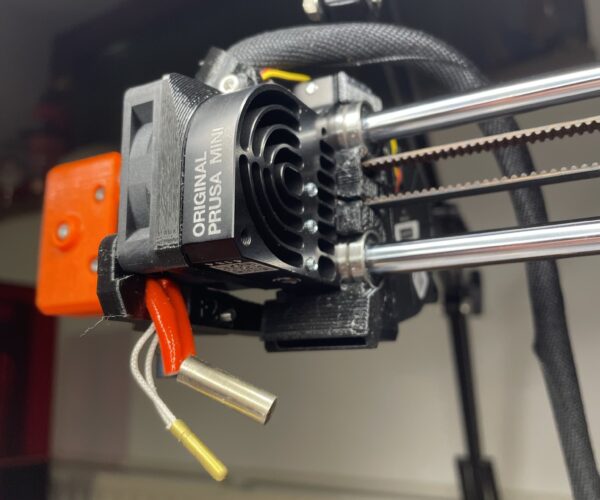

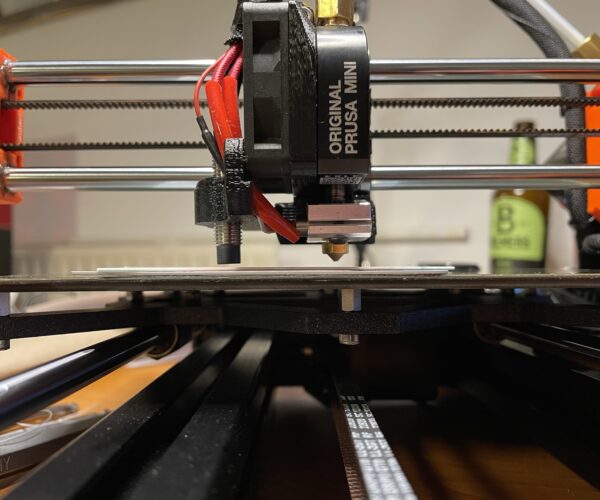

I just got a new Mini+ preassembled original. I printed some test parts and the result was very good. After some prints the extruded filament was sticking to the nozzle so I decided to clean it (20 prints totally). I wanted to take out the filament but as the printer said "ready" I was not able to pull the filament out, so I disassemled the extruder:

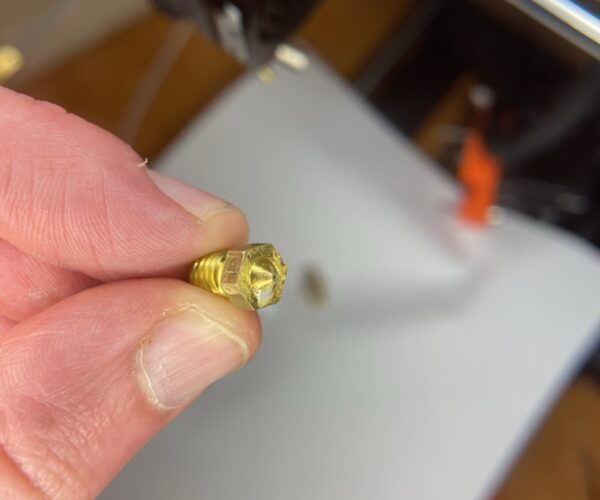

As I cut of the stucked filament I pulled it out I thought it was a good idea to take out the nozzle. After I did this, I saw that there was still a bit oft PTFE tube still in!?

I will disamble the hotend, put a new PTFE tube and nozzle in but I was wondering what I was doing wrong?

With original Prusa Mini, it's impossible that PTFE tube would be inside the nozzle. Is it possible that this are remains of white filament that you used?

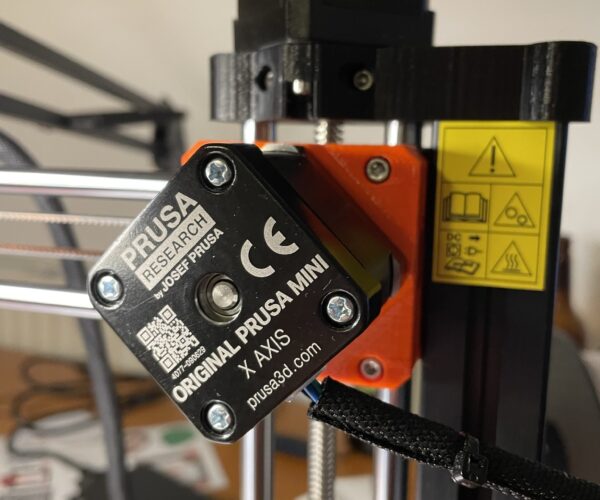

I can see a lot of stringing remains on extruder housing and that's not how Prusa print parts -it looks more like someone else printed that. Ok, I will say out loud: if that's really PTFE tube inside nozzle and the way extruder housing is printed, I think that's not original Prusa.

[Mini+] [MK3S+BEAR]

Original Prusa?

Hi Bogdan, well, I haven't thought about it that it could be rest of PLA, but you are right. I used white PLA! So my question would be: Is that normal?

I bought the printer directly at Prusa Research, but there are a lot of parts with stringings. I noticed this too and I was a bit disapointed because a friend of mine made a Mini+ Clone on his Voron and it looks more better and has no problems at all after weeks of printing.

Head-palm

Oh my. Removing the filament does not require disassembling the extruder. That's all I'll say.

Head-Palm

Hi Dan, thanks for your reply. How would you have managed it then? I was pulling it so hard that the filament almost broke. the extruder inside had a lot of messed up filament in it. How do I clean it without disassembly?

Prusa Online Docs

Oh my. Removing the filament does not require disassembling the extruder. That's all I'll say.

According to the online docs, Prusa wants to do exactly what I did to clean my extruder when it's messed up with filament:

https://help.prusa3d.com/en/guide/how-to-access-and-clean-the-extruder-pulley-mini-mini_126457

RE: Filament stuck, nozzle dirty, PTFE tube broke...

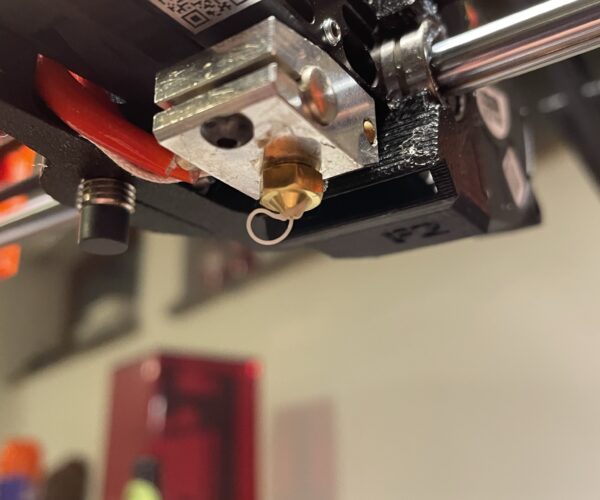

An original E3D nozzle looks like this:

The hole in the threaded area should not be larger than 2mm. For PTFE, this area is much too hot and the too large hole (i think about 4mm) will cause clogging. I would possibly change the nozzle.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

E3D nozzle

Hi Karl,

thank you very much! I am totally confused now, because that nozzle looks not like mine!? Again, I bought and got this printer right away from Prusa research.

It's Prusa Mini

An original E3D nozzle looks like this:

It's about Prusa Mini (posted in wrong forum section)

[Mini+] [MK3S+BEAR]

RE: It's Prusa Mini

The same nozzles (so Prusa) are installed on the Mini, MK2/S, MK2.5/S and MK3/S. However, the hole in the filament inlet area should not be larger than 2mm (for 1.75mm filament).

https://shop.prusa3d.com/en/accessories/1168-nozzle-04-mini.html

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

thread moved to Mini section of forum!

hi folks, I have moved this thread to the Prusa Mini section of the forum.

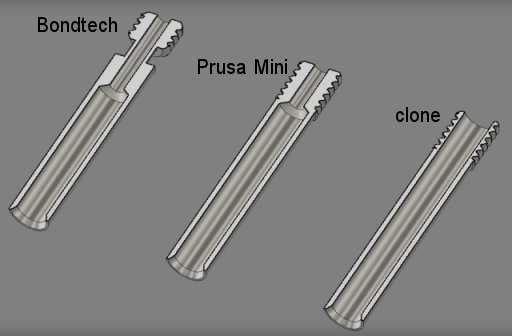

the mini has a different heatbreak set up to the mk3 or mk2 printers

the heatbreak is drilled 4mm clearance and there should be PTFE tube between the top of the hot end, and the top of the nozzle, to guide the filament to the nozzle

it would appear that filament is getting under the ptfe tube at the top of the nozzle

this article may help

https://help.prusa3d.com/en/guide/how-to-replace-a-hotend-ptfe-tube-mini-mini_119449/

step 8 in the article below describes how to trim your hot end PTFE

Note, the three grub screws in the heatsink, are easily damaged, you may wish to replace them with m3 socket head screws

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: E3D nozzle

If this nozzle was installed on your original Prusa Mini in this manner, I would contact Prusachat and request a replacement.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: E3D nozzle

If this nozzle was installed on your original Prusa Mini in this manner, I would contact Prusachat and request a replacement.

wbr,

Karl

Yes, I haven't touched anything which came pre-assembled until now, becuase I thought I made something wrong while printing. Also my Z-Axis was more than 4mm off after assembly which I had to readjust because it couldn't be leveld by the autoleveling (tried it and scratched my 5 min old printers bed.). Overall I had a really bad experience, but I am going to make some detailed pictures and get in touch with the Prusachat and see if they can help me. Thanks so far!

The same nozzles (so Prusa) are installed on the Mini, MK2/S, MK2.5/S and MK3/S. However, the hole in the filament inlet area should not be larger than 2mm (for 1.75mm filament).

https://shop.prusa3d.com/en/accessories/1168-nozzle-04-mini.html

wbr,

Karl

I apologize... I had "hotend" in mind when I was typing.

And good catch about nozzle inner hole!

Bad printed parts, wrong nozzle type... now I'm pretty sure OP actually has PTFE inside nozzle, because he has cloned heatbreak made in china:

My opinion... that Mini didn't came from Prusa -but I'm always ready to be proved wrong.

[Mini+] [MK3S+BEAR]

I'm always ready to be proved wrong

The same nozzles (so Prusa) are installed on the Mini, MK2/S, MK2.5/S and MK3/S. However, the hole in the filament inlet area should not be larger than 2mm (for 1.75mm filament).

https://shop.prusa3d.com/en/accessories/1168-nozzle-04-mini.html

wbr,

Karl

I apologize... I had "hotend" in mind when I was typing.

And good catch about nozzle inner hole!Bad printed parts, wrong nozzle type... now I'm pretty sure OP actually has PTFE inside nozzle, because he has cloned heatbreak made in china:

My opinion... that Mini didn't came from Prusa -but I'm always ready to be proved wrong.

Hi Bogdan,the printer I am showing here is 100% original Prusa. I have it bought from Prusa Research und got it delivered right away from Prusa in original Box etc. I agree that some parts do not look like very good, but I am willing to work through the issue. I will contact Prusa meanwhile Prusa directly, because I have all workflow trough buying, shipping, billing in my Account. I ordered some new nozzels and will reassemble the printer tomorrow to see result. The nozzels I ordered will not be original prusa, but I will keep the rest original. See some pictures:

I will let you know the result! Still no idea what I made wrong.

Thank you for showing additional photos. Not that you have to prove anything -it's just easier to help if there are no doubts.

As it seems, the only mystery is nozzle... as Karl pointed out, original E3D (Prusa) nozzle input diameter is 2mm. And after this is solved with Prusa, I think it should be fine.

[Mini+] [MK3S+BEAR]

wrong nozzle

I can confirm 100%. I have a Mini myself. The heatbreak on the photo seems ok (original Prusa (no Bondtech) with 2mm hole). You just need a correct nozzle with the same hole diameter as on the heatbreak thread side (2mm). I would definitely contact Prusa (via chat, not email).

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

Update with new nozzle

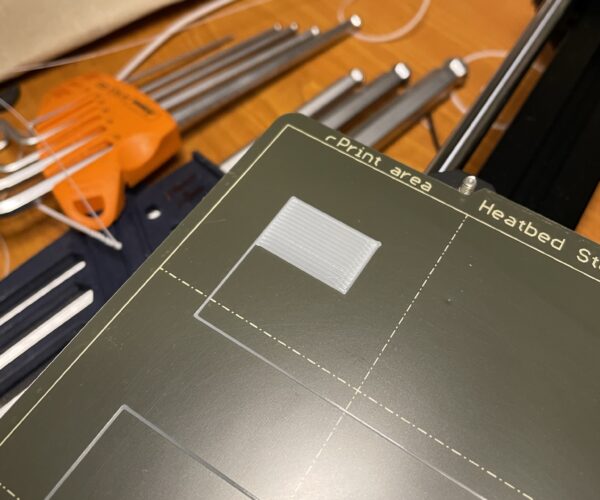

Hi guys. Here is my update. I reassembled my hotend with the new nozzle. After that I realized that my Z was way off (3mm). So for any reason my hotend was way more in than before. I used the same hotend, PTFE tube etc.

I was following the instructions to level Z and make the first layer by putting up the PINDA a bit and the result was fantastic!

The only thing I noticed is that some PLA was sticking to the nozzle which I can take off after cooling easily

I might have to set Z a bit higher that my nozzle don't collect PLA, but I think that needs just some testing. I also unload and load the filament which works great so far (2 times). Hope I can figure out what the problem was. I am getting a bit more used to the printer and understand the assembly which helps a lot.

I really appreciate your help!

I'm glad you made it! Yes, now you print some stuff and then decide if you need additional adjustments -first layer looks ok, though.

Thank you for reporting

[Mini+] [MK3S+BEAR]