Filament always jams in PTFE tube when unloading / unable to use other filament

Hey guys, I recently got my Mini in the mail, and while it's been churning out awesome prints with the kg of prusament I got, I've unfortunately run into an issue: it can never unload by itself. I've had to take apart the ptfe tube and push out this little clog every time as it's too big to pull back into the tube.

In addition, when I try and use either of the other 2 spools I bought (paramount3D branded - seemed to have quite good reviews), they both get stuck in the feeder and fail to extrude entirely, ending chewed up and sometimes broken into pieces once I remove them. I measured both with calipers and theyre both within .05mm of 1.75, so I'm not sure what's happening there. I would have chalked it up to a bad spool were it just one causing problems, but both having the exact same failure seems strange. I did already clean the gears in the feeder; and it is quite strange - it loads the filament with no problems, and when I purge excess, it flows perfectly well, but has issues as soon as I try and start a print.

However, once I switch back to my roll of prusament, it prints fine.... any idea what's happening here? Thanks for any advice you can offer.

RE: Filament always jams in PTFE tube when unloading / unable to use other filament

Two things come to mind - at least to me

1. Extruder idler tension - make sure it's flush with the body when no filament is loaded

2. Hotend position - can you see any threads sticking out? It might be too low.

RE: Filament always jams in PTFE tube when unloading / unable to use other filament

Threads sticking out are fine! The distance between heatblock and heatsink should be 4,8 mm.

But yeah, reseating/replacing the PTFE tube in hotend is probably the correct solution. There are many topics about that and it's common issue with Mini which is a shame.

RE: Filament always jams in PTFE tube when unloading / unable to use other filament

@pitel

I moved mine up right away so no that no threads were showing. I've had no issues so far 😉

RE: Filament always jams in PTFE tube when unloading / unable to use other filament

Threads sticking out are fine! The distance between heatblock and heatsink should be 4,8 mm.

But yeah, reseating/replacing the PTFE tube in hotend is probably the correct solution. There are many topics about that and it's common issue with Mini which is a shame.

4.8mm is the Prusa recommendation. But Prusa keep delivering printers to users which perform poorly, so I am going to say that the Prusa official Prusa setup is not effective.

I swapped the PTFE tube for the spare, but still had problems after that, so its a workaround not a fix. What worked for me was moving the heatbreak as far up as possible.

The Prusa hotend is quite subtle and sensitive to how it is assembled. Interestingly, my cooling fan was running too slow because a cable was rubbing against it, and I had exactly the same underextrusion symptoms. It seems any excess heat getting into the heatbreak causes the filament to swell, and if you have any gap between the PTFE and the metal there is potential for a jam to occur in the hotend.

Add the fact the olives on the PTFE constrict the diameter slightly, and then you get problems unloading. I think Prusa may have succesfully reduced the cost of the hotend, but the downside is it only works well if perfectly set up. Stray outside the perfect setup and you get problems.

RE: Filament always jams in PTFE tube when unloading / unable to use other filament

hey guys, thanks for the help. yeah, since making this post, I've seen that its quite a common issue haha....

going to try reseating the hotend ptfe and adjusting the position to check that first, and I also happen to have a local retailer with the bondtech heatbreak upgrade in stock should I feel like trying that. until then, printing out the rest of my roll of prusament, as that does still print flawlessly..! wish I could get more for now but that's very out of stock here, haha.

RE: Filament always jams in PTFE tube when unloading / unable to use other filament

@bops

Interested in hearing if your recent changes helped at all.

RE: Filament always jams in PTFE tube when unloading / unable to use other filament

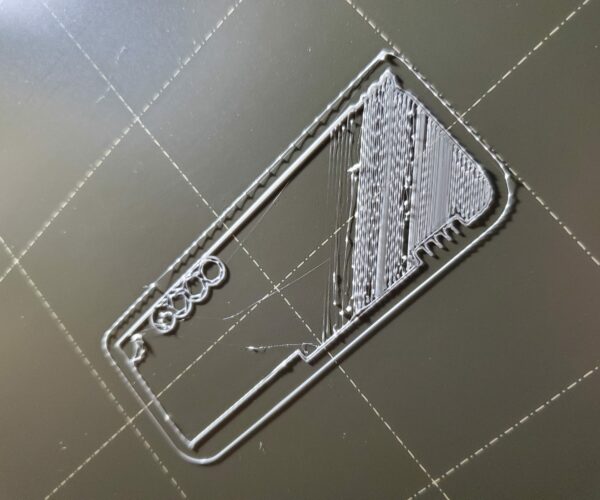

These filament endpoints looks exactly like the once I had before pushing the heatbreak up a bit, it was ~4-5 mm to low. The reason they look like that is due to a gap forming between the PTFE-tube and the lower end of the heatbreak, so push the heatbreak up, should be a gap of 5 mm between the hotend heater block and the bottom of the fan. A better choice is the Bondtech heatbreak which I installed.