Could not print flawlessly a simple 4x4x36 mm cylinder

I was printing a fox figure with thin legs using my Prusa Mini at 0.15 mm thickness using Prusa filament “Prusament Premium PLA Mystic Brown”. All settings were default using PrusaSlicer. Suddenly the thin legs became inconsistent and I cancelled the print. I managed to reproduce the issue by printing a simple tall cylinder 4x4x36 mm with a brim using the same settings.

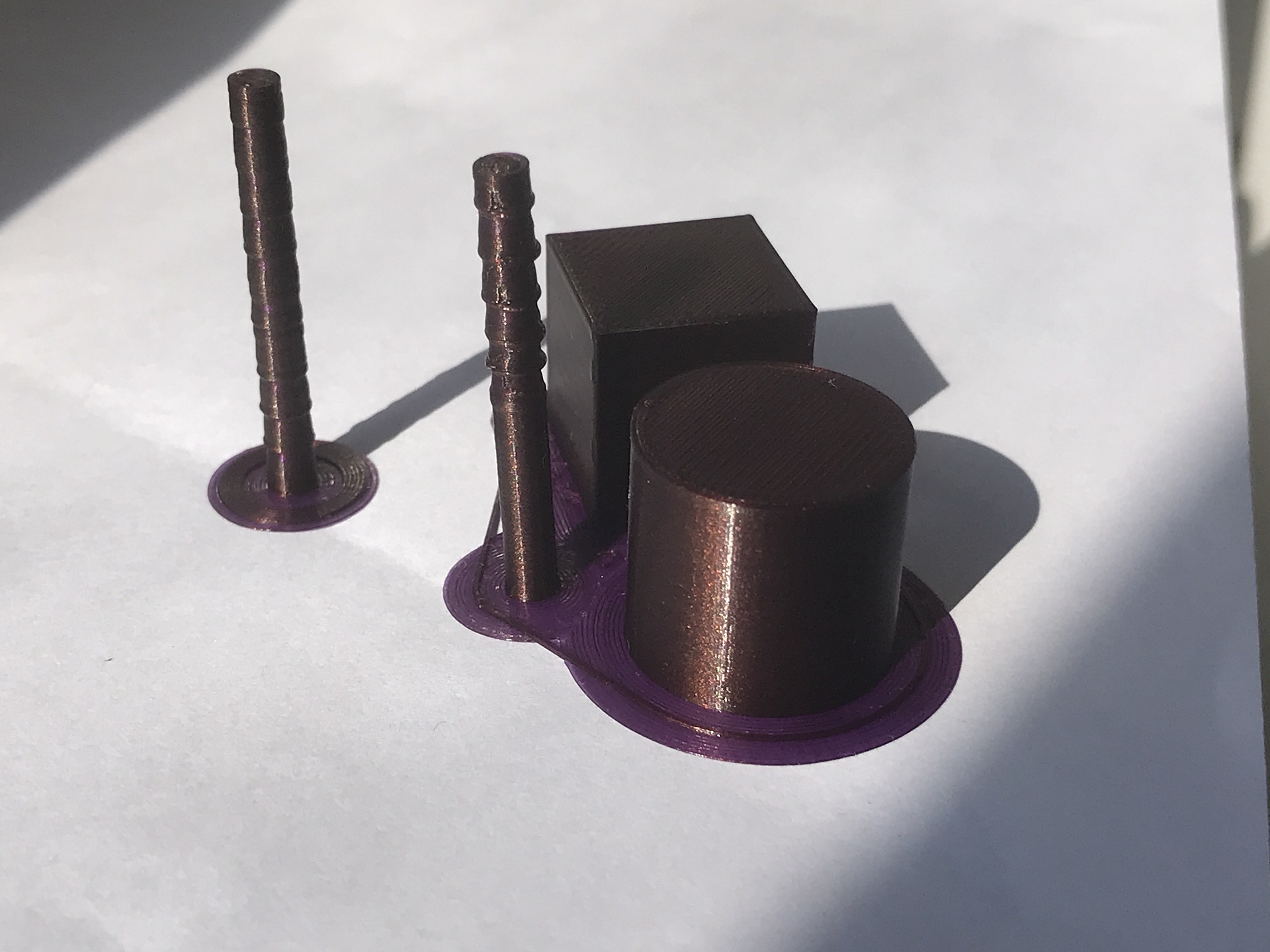

The result was that every few millimeters on Z axis the tall cylinder produces a thicker layer/s. I printed the same tall cylinder together with a cube and another cylinder and the issue did not appear until all three figures were printed together. The issue appeared again after the tall cylinder remained the only object to print, as seen from the picture – on the left is the stand alone printed tall cylinder and on the right is the same tall cylinder printer together with the two other figures:

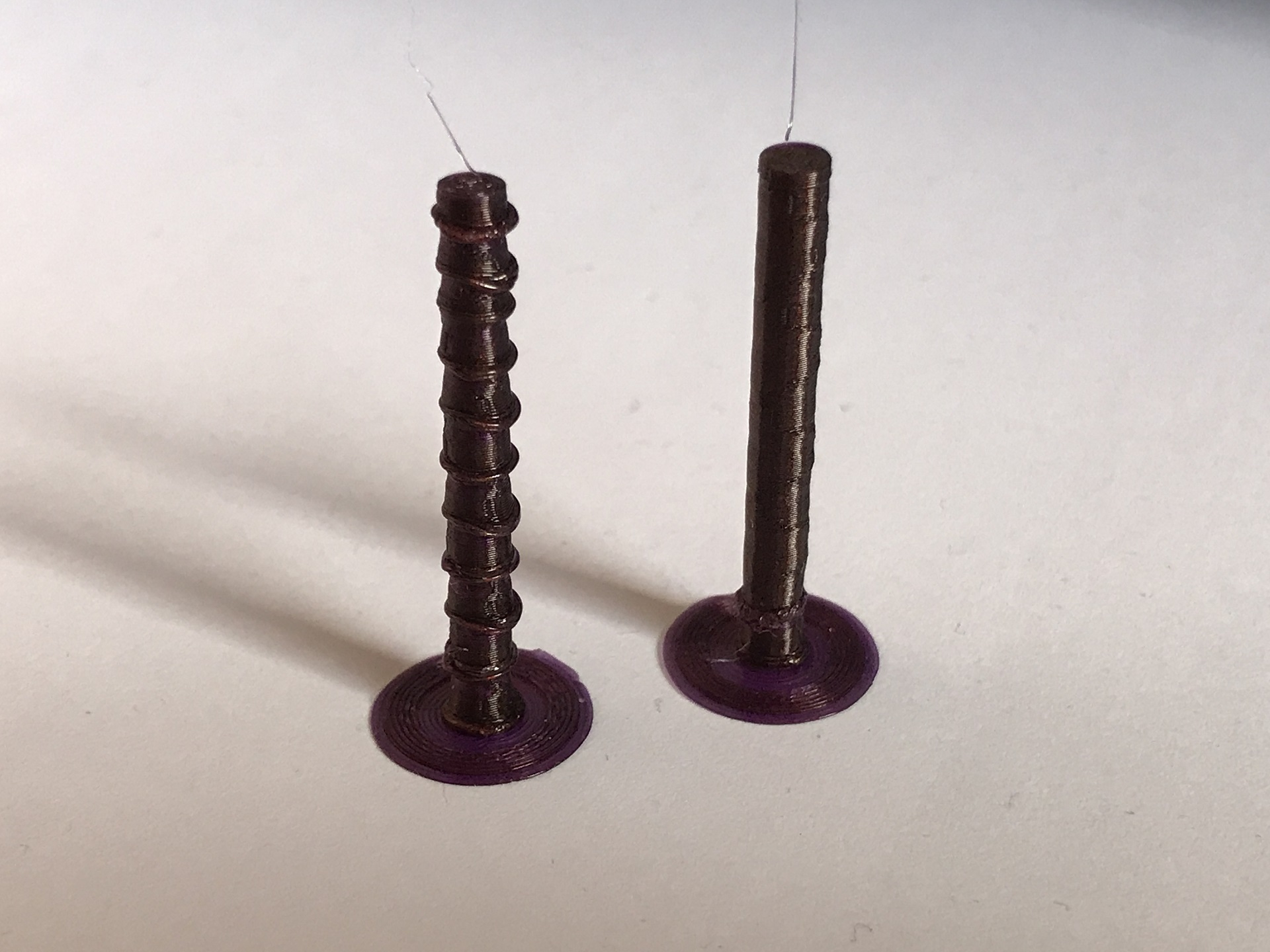

I tried slowing down the printing speed which worsened the problem. Also printing at 0.07 mm. thickness (again using default values from PrusaSlicer) worsened the problem. Finally raised the default temperature from 215 to 230 degree Celsius and this nearly solved the issue as seen from the picture – on the left is the tall cylinder using 215 degree Celsius and slower speed and on the right is the same cylinder printed using 230 degree Celsius:

I carefully monitored the whole printing process and found that on every layer the Bondtech extruder picks some filament until suddenly it skips picking up filament for 2-3 layers then continues and may be this is causing the described issue. For me there is a problem with inconsistent/uneven flow of the filament.

I am using Bondtech Dual Drive Extrusion and Heat-break Upgrade Kits. I have inserted the required by Bondtech GCodes in the slicer before the ; intro line: M92 E415 (for the extruder) and M301 P16.33 I1.41 D47.34 (for the print head autotuned to my printer as Bondtech support recommended).

Would someone else print the same cylinder in order to compare the results?

Any guides / know-how to fix this?

RE: Could not print flawlessly a simple 4x4x36 mm cylinder

I am using Bondtech Dual Drive Extrusion and Heat-break Upgrade Kits. I have inserted the required by Bondtech GCodes in the slicer before the ; intro line: M92 E415 (for the extruder) and M301 P16.33 I1.41 D47.34 (for the print head autotuned to my printer as Bondtech support recommended).

The value 415 is only a theoretical value and depends on mechanical components. I would perform a calibration after installing the Bondtech:

https://mattshub.com/blogs/blog/extruder-calibration

The same applies to the P.I.D. values. The PID tuning must be performed and adjusted for each printer individually:

https://mattshub.com/blogs/blog/pid-tuning

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Could not print flawlessly a simple 4x4x36 mm cylinder

As a small recommendation - don't print tall thin pieces alone. Print something else next to it, second piece or something. If you print only one print like that, material has no time to cool down and you get ugly melted print. Head moving to another object gives enough time to cool down.

RE: Could not print flawlessly a simple 4x4x36 mm cylinder

As a small recommendation - don't print tall thin pieces alone. Print something else next to it, second piece or something. If you print only one print like that, material has no time to cool down and you get ugly melted print. Head moving to another object gives enough time to cool down.

Ok, but when at the end you have tall ears or horns of animals? Put a tall cylinder next to the animal to solve the issue?

RE: Could not print flawlessly a simple 4x4x36 mm cylinder

@sth-udoma

That's actually a valid solution people sometimes use when printing minis for example, or print more copies at once. Horns and stuff are hard to print, 2 ears or 2+ horns may be doable but one is tough and those prints usually don't look as good. Only thing I can come p with is maybe increasing cooling, but if you don;t want to do that for the whole print (Filament Settings -> Cooling) you may need to do kludges like do a filament change at certain layer height and pretend it's different filament with different cooling parameters.

RE: Could not print flawlessly a simple 4x4x36 mm cylinder

I went deeper and found that GCode (attached) produced by PrusaSlicer is not consistent across all the layers. I mean there are two type of layers and for convenience I will name them TypeA and TypeB. They are following one after the other at 0.15 mm thickness: 16 layers TypeA (height from 2.45 up to 4.7) , then 8 layers TypeB (height from 4.85 up to 5.9), then again 16 layers TypeA (height from 6.05 up to 8.3), 8 layers TypeB (height from 8.45 up to 9.5), etc.

The difference is that TypeA has additional lines after the layer is printed they instruct the extruder to retract -3.2 ((-2.24)+(-0.22)+ …) and then move forward again 3.2. Here are all the extra lines in TypeA:

G1 X88.868 Y89.030 F9000.000

G1 E-2.24000 F4200.00000

G1 F7200.000

G1 X88.746 Y88.746 E-0.22058

G1 X89.007 Y88.530 E-0.18790

G1 X89.336 Y88.355 E-0.20659

G1 X89.661 Y88.259 E-0.18786

G1 X89.857 Y88.240 E-0.10907

G1 E-0.04800 F4200.00000

G1 Z2.600 F9000.000

G1 X90.850 Y89.404

G1 Z2.450

G1 E3.20000 F2400.00000

M204 S1000

G1 F900

G1 X90.000 Y89.203 E0.02275

G1 X89.657 Y89.023 E0.01010

So every 16 layers a retraction is used followed by 8 layers without retraction. What I see live is that after the retraction is back under lower temperatures it immediately causes the thicker sections/rings on the tall cylinder that appear every 24 layers.

Anyone knows why is that and how could I manage that process and have no 16 + 8 + 16 but all the layers to be consistent in the Gcode?

RE: Could not print flawlessly a simple 4x4x36 mm cylinder

Here is the PrusaSlicer 3MK file attached.

RE: Could not print flawlessly a simple 4x4x36 mm cylinder

FIXED: The solution for this strange problem is in this post: https://forum.prusa3d.com/forum/prusaslicer/how-to-set-consistent-printed-layers/#post-284356