Clogged nozzle - after PTFE tube reset and cold pull?? 😩

Hi All,

New Prusa Mini+ as of 10th Feb. (ie. 2 months old). Trouble initially will z-axis calibration and then all good.

22 prints to date including + 2 supplied UBS gcode prints. So not a heap of work.

Last attempted print was a small insert to go into a Minecraft cube lamp. Filament eSun PLA Glass Purple. Already printed small tester in the colour filament 24 hours prior.

No filament extruding when starting the print. Tried test print

Only a small amount of filament extruded.

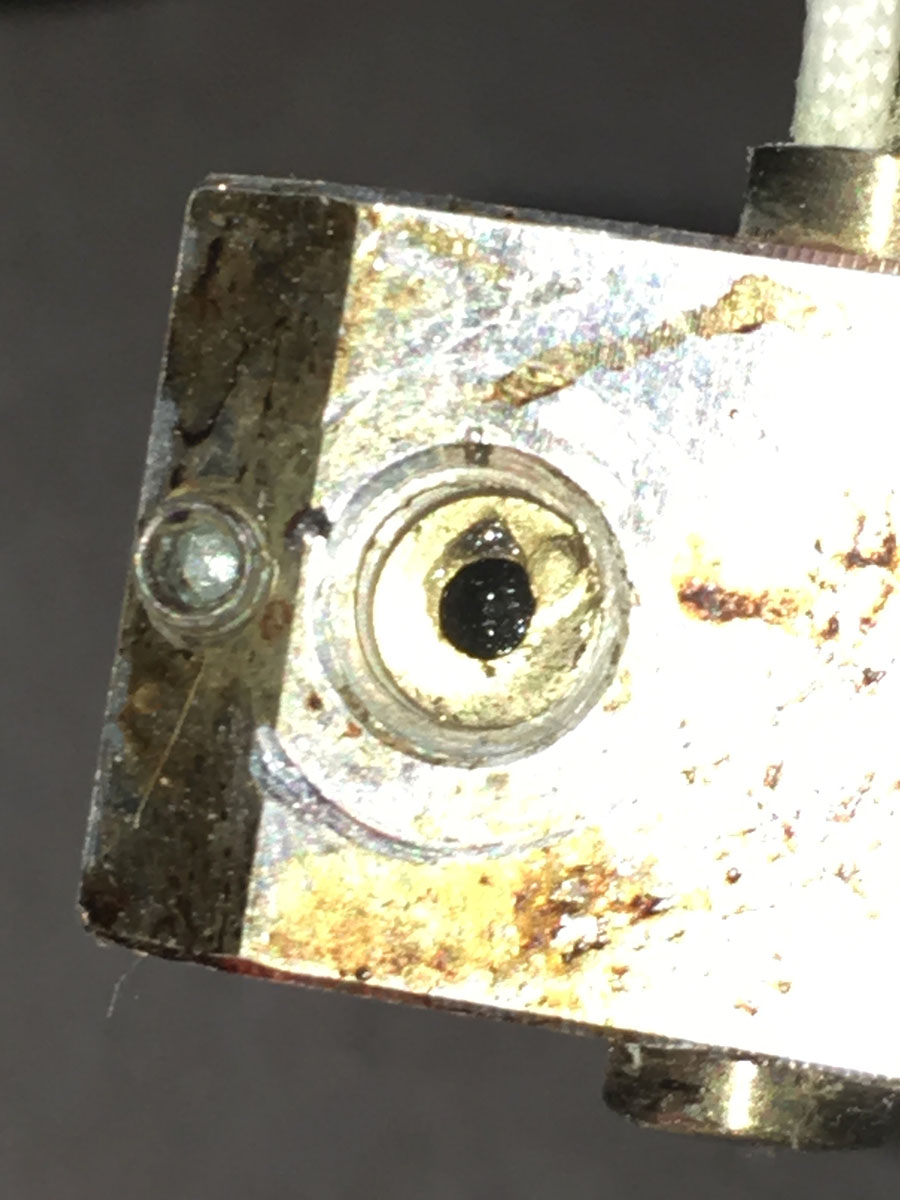

Swapped filaments over and had the same result. Ok, so a clogged nozzle. Removed the Nozzle to check .

Images confirmed nozzle definately clogged.

Onto Prusa support site to find fixes for this.

Working from https://help.prusa3d.com/en/article/clogged-nozzle-hotend-mini_112011

Tried :

- Heating the hotend to 260˚C to melt the filament out. No better.

- Cold pull of filament after removing the bowden tube and PTFE liner.

The (restricted view) into the hotend indicated that there was filament stuck down in there.

3. The cold pull resulted in some of the PLA Glass Purple filament being removed.

4. Forcing filament through the hotend with the bowden tube off and the PTFE liner out - a small stream of filament exiting the nozzle

Continued with re-positioning the heat break with removing the 3 grub screws - no apparent movement. Reconnected the bowden tube.

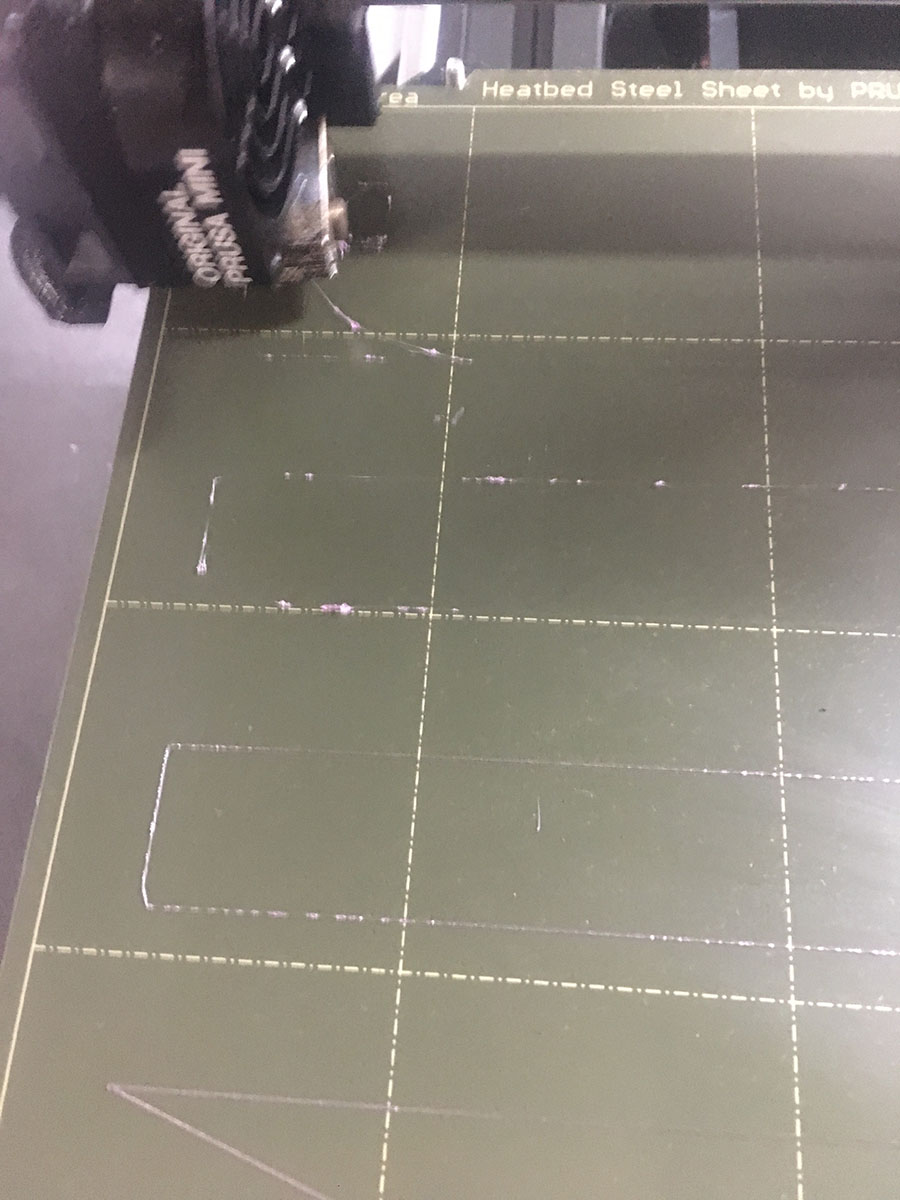

Ran the 'First Layer Calibration' from the calibration menu. Selected the current Z-axis offset to perform. MISTAKE!!!

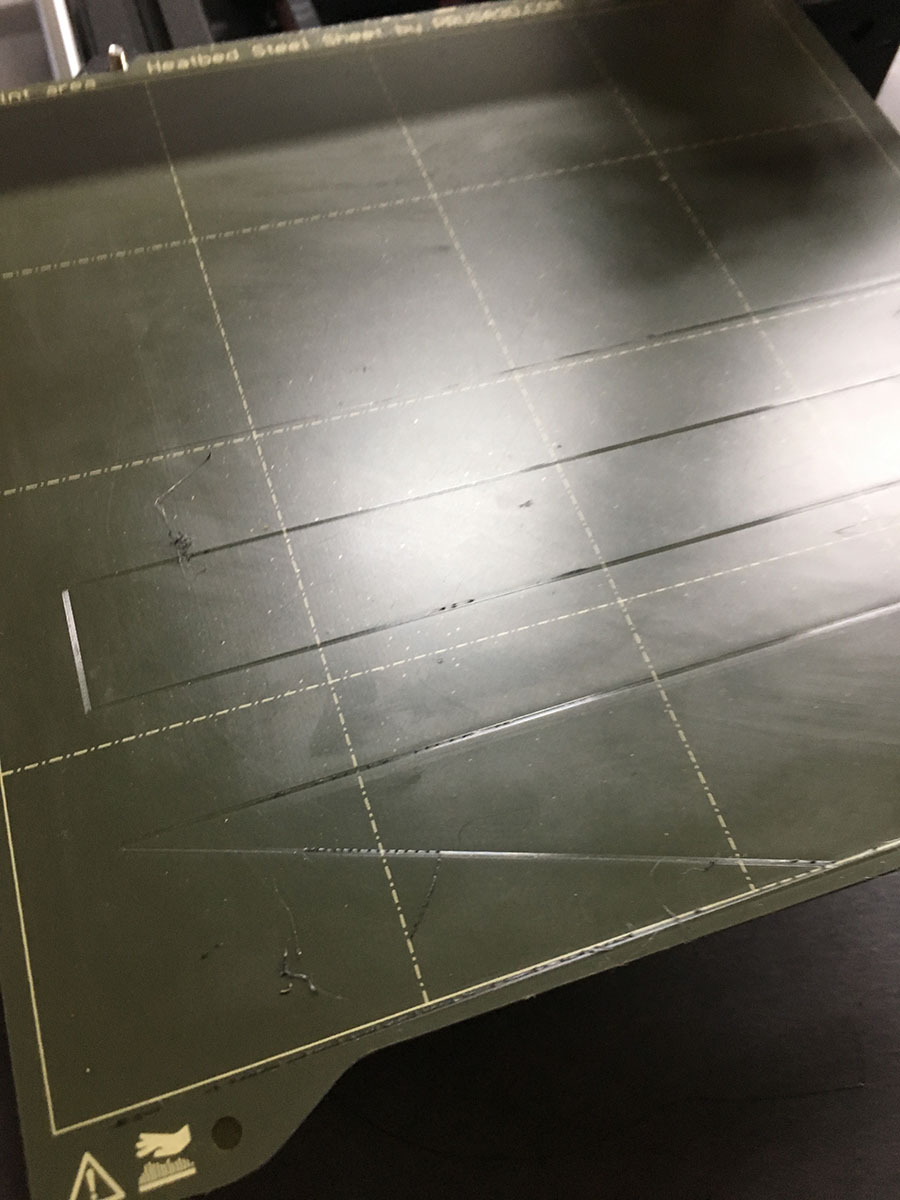

Bed level pinda test was ok. BUT then when the print started, THE NOZZLE GOUGED THE STEEL PRINT BED. 🙁

Aaaaggghhh !!!

Still not extruding filament properly.

What do I do now? Given i've worked the trouble-shooting guide. Still a Clogged Nozzle AND now a damaged print bed.

Q. Does the Nozzle now just need to be replaced?

Q. Do I repeat the process?

Q. Is there a spare nozzle supplied by default?

Q. Should the nozzle clog to this degree?

Q. If replacing the nozzle, should I get a better nozzle? (Hardened Steel / Nozzle-X).

Help Please 😢. Keen to get back to being a Happy Prusa Mini Printer.

Matt.

Prusa Mini+ - Fw. 2.3.1 - PrusaSlicer 2.3.0 (Mac) - Filaments PLA / PLA+ / PETG.

RE: Clogged nozzle - after PTFE tube reset and cold pull?? 😩

Hi,

I'm facing the same problem with my new Mini+ from March.

After very good prints the printer had a clogged nozzel. I heated the Nozzel up to 240° insted of 215 and the blob came out. The first few layers were okay and it clogged again. So I heated up the nozzel, pushed the filament trough while it cooled down and put it out at 100°. Nothing was really stuck at the pulled out filament. Started printing with another filament. Now a few more layers were perfekt until it stopped extruding filament right. The plastic it's extruding looks exactly like the foto on this post. I'm running out of ideas. Espacially because mine was factory assambled. The filament is stored in the basement which ist quiet dry. Printig with higher temperature (like 230) works much much better, but i mean this is not right for PLA. I'm using Amazon Basic PLA with the Pursa Slicer Amazon Basic PLA setting...

I had so much fun with the printer but now i'm stuck 🙁

RE: Clogged nozzle - after PTFE tube reset and cold pull?? 😩

What do I do now? Given i've worked the trouble-shooting guide. Still a Clogged Nozzle AND now a damaged print bed.

Q. Does the Nozzle now just need to be replaced?

Not if you can make it unclogged (acupuncture needle, air heatgun, blow torch, ... - BUT BEFORE DOING SO DISASSEMBLE THE NOZZLE FROM THE PRINTER !!!)

Q. Do I repeat the process?

Give it a try

Q. Is there a spare nozzle supplied by default?

No - so it's time to get some spare nozzles. I would recommend to buy quality

Q. Should the nozzle clog to this degree?

No it should not - but: it happened

Q. If replacing the nozzle, should I get a better nozzle? (Hardened Steel / Nozzle-X).

If printing only PLA, PETG, ABS, ASA, PC stay on brass nozzles - cheap and good

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: Clogged nozzle - after PTFE tube reset and cold pull?? 😩

@clemens-m

Hi Clements,

Thanks for the response.

Further efforts.

1. Removed nozzle from printer. Heated with Micro Butane torch. Some small amount of filament removed.

2. Re-installed in printed. Same result. Filament extruding from hotend BUT in a fine and inconsistant stream (as previous).

😩

3. Purchased new nozzle from a nearby retailer. (E3D in 0.2 / 0.4 / 0.8).

While i'm buying why not opt for some different sizes.

4. Reviewed the Prusa online guide for removing the heatbreak (and heater block).

5. Heated the printer, tried to unload the filament, no love, filament snapped trying to pull out of the sensor.

6. Undid the PTFE tube and preformed a 'cold pull' to remove the filament from the hot end. (worked).

7. Tried to remove the hotend BUT hotend broke in the heater block!! Aaarrgghh.

NB. Inside the nozzle filament was cake up.

8. Released the sheath from the cabling and pushed the cable through to allow the heatbreak to be removed.

9. Released the heatbreak grub screws and removed it with the heater block.

10. Undid the thermistor grub screw - removed thermistor.

11. Tried to remove the heater cartridge grub screw with an allen key. Ruined the head on the screw. Aaarrgghh (no. 2).

12. Used vice-grips / shifter to remove the heatbreak from the heater block.

NB. The inside of the heatbreak was completely clogged with filament.

13. Again, used a micro butane torch to heat the heatbreak and melt the filament.

Result was finally being able to see daylight through the heatbreak.

14. After removing the heatbreak, I notice that the wires for the termistor are damaged. Aaarrgghh (No.3).

15. Post cleaning the heatbreak, I try to re-insert the PTFE tube to discover that the tube is *slightly* distorted and the tube only inserts half way down. Aarrgghh (No. 4).

So in summary. I have :

1. A heater cartridge screw that can't be removed.

2. Broken thermistor wires that need to be re-joined or replaced.

3. A piece of hotend still stuck in the heater block.

And.

4. A heatbreak that will (most likely) need to be replaced.

Pretty annoying stuff for a printer that's only done a dozen prints.

I'll talk to support and see if they can help me with parts.

Got lots of prints queued up to do the Mini - Need to get this fixed.

Matt.

Prusa Mini+ - Fw. 2.3.1 - PrusaSlicer 2.3.0 (Mac) - Filaments PLA / PLA+ / PETG.

RE: Clogged nozzle - after PTFE tube reset and cold pull?? 😩

@aussieinkguy

There are days when you lose and then there are days when you can't win! 😉

But: Don't give up !!! Help is on the forum.

O.k. - what do we have on the list of problems:

- Heatblock with a broken part of the heatbreak in it ==> not that easy to remove - needs heat and tool

- Heatbreak ==> spare part necessary

- Broken thermistor wires ==> could be repaired, depends on your skills - soldering and isolation

- Screw for clamping heat cartridge destroyed ==> if you have a tool like a dremel with a thin grinding wheel you can grind a slot for a screw driver, again heat is necessary to open the screw

May I ask where you are from - regarding supply with spare parts (USA?)?

I had a look into eshop:

Heatblock: (€12,-)

https://shop.prusa3d.com/de/minimini/1171-hotend-heaterblock-mini.html

Hotend thermistor: (€10,-)

https://shop.prusa3d.com/de/mk3mk3smk3s/205-hotend-thermistor-e3d.html

Hotend heatbreak: (€10,-)

https://shop.prusa3d.com/de/minimini/1177-hotend-heatbreak-mini.html

(There are lots of people also use other than the original heatbreak)

PTFE-tube hotend: [€1,-)

https://shop.prusa3d.com/de/minimini/1084-hotend-ptfe-tube-mini.html - I would buy such a PTFE-tube in one peace - lets says 1m or something like that and cut it by my own.

I am sure that your problem was caused by the small PTFE-tube - lots of people have problems there.

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: Clogged nozzle - after PTFE tube reset and cold pull?? 😩

@clemens-m

Hi Clements,

Not giving up, just working the process.

Yes, new parts are the go. Will most likely purchase all parts required and re-wire the thermistor, but order one just in case.

I'm based in Australia (as per the username ;-)). So, shipping is expensive. I already have a spare PTFE tube that shipped with the printer + Capricorn tubing spare from my ender 3 upgrade.

Do you have a mini? and have you replaced the heatbreak? If so, did you use Prusa or a 3rd party and if so, your thoughts.

More updates to follow...

thanks again.

Prusa Mini+ - Fw. 2.3.1 - PrusaSlicer 2.3.0 (Mac) - Filaments PLA / PLA+ / PETG.

RE: Clogged nozzle - after PTFE tube reset and cold pull?? 😩

@aussieinkguy

I have replaced two of my four heartbreaks on my minis with 3rd party products. One with a Bondtech and one with Triangle Labs. Both work.

--------------------

Chuck H

3D Printer Review Blog

RE: Clogged nozzle - after PTFE tube reset and cold pull?? 😩

@cwbullet

Hi Chuck,

Were they replaced due to failure? or as a performance upgrade?

Of the 3, Original / Bondtech / TriangleLabs, which one is your favourite? and why?

Thanks.

Prusa Mini+ - Fw. 2.3.1 - PrusaSlicer 2.3.0 (Mac) - Filaments PLA / PLA+ / PETG.

RE: Clogged nozzle - after PTFE tube reset and cold pull?? 😩

Bondtech - I added it to replace a PTFE line heat break. It functions as well as the Prusa with less jams. I cannot quantify that. On my Prusas, I get a jam a month or two.

Triangle labs works about the same as the Prusa. I added it to just mess around.

--------------------

Chuck H

3D Printer Review Blog

RE: Clogged nozzle - after PTFE tube reset and cold pull?? 😩

@aussieinkguy

Sorry - have lost sight of this topic! I own also 1 Mini which is completely original. I only once had this typical problem with the Hotend completely glogged. Since then never again a problem (still with original parts - even the first PTFE-tube).

Goodl luck !!!

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)