Calibration for stringing

I am trying to reduce the stringing for Fillamentum PLA Crystal Clear.

https://www.fillamentum.com/collections/pla-crystal-clear-filament

Tried a few settings and not much results except setting temp to 210C

Best result from lowering from default 215C to 210C

Best result from lowering from default 215C to 210C

Fillamentum shows the min temp is 210C

https://www.fillamentum.com/collections/pla-crystal-clear-filament

How can I better calibrate to reduce stringing further?

RE: Calibration for stringing

I've got notes on the process I used to eliminate fine stringing here that you might find useful.

RE: Calibration for stringing

I've got notes on the process I used to eliminate fine stringing here that you might find useful.

Thanks!

Are you able to guide me on a few things?

i dont understand most of the stuff in it.

2)

I can see my perimeter: 3

but...

where is perimeter extrusion widths ?

3)

any file for the cube?

i dont know how to create my own print

>Linear advance

Do i need to do this?

>Z-seam

my print looks good to me, so I wont change this.

Thanks!

RE: Calibration for stringing

[...] where is perimeter extrusion widths ?

Look under Print Settings->Advanced.

any file for the cube?

Any 2omm cube will work. You can generate a quick one in PrusaSlicer as follows:

- Right-click on the print bed and select Add shape->Box.

- Click on the box and change the dimensions in the size settings on the right.

- Change Print Settings->Layers and perimeters to 2.

I've attached a simple 20mm cube STL to save you on steps 1 & 2.

- Change Print Settings->Infill->Fill density to 0.

>Linear advance

Do i need to do this?

Not right away. It probably won't affect stringing as much as the other factors. It's not hard to do though.

>Z-seam

my print looks good to me, so I wont change this.

That's fine. Tweaking the extrusion multiplier will tend to minimize the Z seam.

RE: Calibration for stringing

I created by own cube

20mm size.

Print settings - Layers and Perimeters - Vertical shells - Perimeters -> 2

Print settings - Infill - Infill - Fill Density - 0%

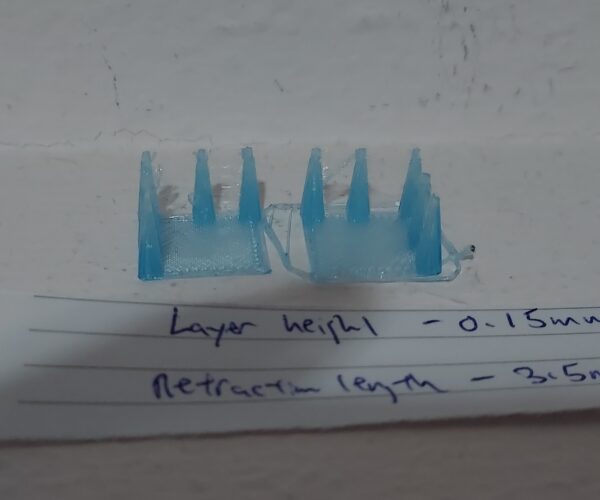

Results in picture below and next step

4) Measure the wall thickness on each wall.

I am kinda confused by this.

How do i do this?

Do i cut up the cube?

RE: Calibration for stringing

You missed the bit where it says to set your top layers to zero and set infill to zero. That will give you an open topped cube with just a bottom and the walls.

RE: Calibration for stringing

I'll update the notes to be a bit more clear. You don't want to get too hung up on precision, but just identify if you need to decrease or increase the extrusion multiplier a little bit.

PrusaSlicer doesn't produce walls of exactly the extrusion width once you go with more than one perimeter, so use that procedure as a rough guide.

RE: Calibration for stringing

Ok, I confirmed that my filament-extrusion multiplier is 1

next is the retraction, z-lift, Retraction speed, de-retract speeds calibration.

what is the min and max value for them?

RE: Calibration for stringing

i notice melted filament clumps or pulled together when making multiple small turns or movements in a row

e.g a small circle or zigzag

what could have caused it?

RE: Calibration for stringing

Ok, I confirmed that my filament-extrusion multiplier is 1

Start at 1 and adjust up or down 1-2% based on your measurements. Very slight over or under extrusion can cause problems. Think of this as a final fine-tuning step for each filament.

next is the retraction, z-lift, Retraction speed, de-retract speeds calibration.

what is the min and max value for them?

All of those settings are under Printer Settings->Extruder 1 in PrusaSlicer.

RE: Calibration for stringing

I tried to set multiple extruder but only extruder #1 is printing well.

the other extruder does not print the "outer" perimeter before zigzag inside.

My steps:

Printer Setting - General - Capabilities - Extruders - 4

Extruder 2,3,4 appear.

i went to change the setting in Extruder 2,3,4 accordingly.

Click on each model to specific Extruder #1,2,3,4

whats wrong?

RE: Calibration for stringing

I changed a new spool of filament and i get better results.

very fine string and no blob stringing.

i think my old filament is too moist.

My question,

1) how much stringing is too much or tolerable?

2) Is drying a spool going to save it when it already "over" expose to moisture? I dried by old filament many times using a food dehydrator. And seems that it didnt help

RE: Calibration for stringing

I changed a new spool of filament and i get better results.

very fine string and no blob stringing.

i think my old filament is too moist.

Sounds like it.

2) Is drying a spool going to save it when it already "over" expose to moisture? I dried by old filament many times using a food dehydrator. And seems that it didnt help

Read up on drying your filament. 50-55C for 3+ hours works for me for PLA. Make sure it doesn't get too hot!

My question,

1) how much stringing is too much or tolerable?

That's really up to you. I don't mind a few threads, and a quick pass with a hot air gun usually cleans those up. If you're getting enough to cause problems with the print or require extensive cleanup, definitely dry the filament.

Read up on drying your filament. 50-55C for 3+ hours works for me for PLA. Make sure it doesn't get too hot!

My question,

1) how much stringing is too much or tolerable?

That's really up to you. I don't mind a few threads, and a quick pass with a hot air gun usually cleans those up. If you're getting enough to cause problems with the print or require extensive cleanup, definitely dry the filament.

I use 50-55C for 3+ hours for PLA. Try a bit longer. I find most filaments will recovery pretty well after drying, but it may vary by brand. If you're not having any luck getting rid of stringing with any filament, it may be time to try adjusting your slicer settings (retraction, etc.)