Bowden tube fittings

Has anyone received a Mini with Festo fittings instead of the brass compression fittings? The reason for asking is that I am designing adapters to use other hotends on the Mini using the existing Bowden configuration.

Mine is brass compression but the pictures on the product page and blog show chrome Festo while the parts page shows compression. This was brought to my attention by a thread in Reddit.

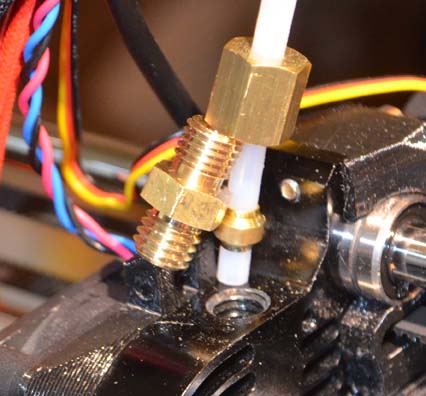

My compression fittings:

Below image from product page showing Festo:

Reddit thread has some suggesting Festo was prototype and early models with compression being the final production. Others are saying that is reversed with Festo to come 🙂 Thank you for your time. Jerry.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

RE: Bowden tube fittings

My mini came with the brass fittings. I think every mini has them, not sure why there's the festo ones in the picture in the eshop

RE: Bowden tube fittings

Thanks. As I see the Festo fittings in the Prusa videos and photos, dating from October-December 2019, I will assume that they were just for prototyping and will design my adapters for the compression fitting.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

RE: Bowden tube fittings

Does anyone know if you can buy those brass compression fittings somewhere? They are not in the Prusa spare parts shop (unless you buy a while heat sink). And I'm so terribly sick of those shitty "Festo" fittings that really is a single direction fitting that destroys the PTFE tube on use.

RE: Bowden tube fittings

Depends on location. Here in the US, just Google, "M8 brass compression fittings", and you will find multiple sources. The thread into the heat sink on my unit is M8x1 with the tube OD of 4mm.

Note that the sleeve that slides onto the PTFE tubing gets compressed 'onto/into' the tube when you first tighten it (it comes compressed from Prusa). I know this also from working with the same set-up on robotic pneumatics. This essentially means it is non-removable. I do agree that with these fittings, and our low preassure use, you can remove/insert the tube multiple times to clear clogs or whatever, and the tube is only 'squeezed' once vs. each time if you reinsert into a Festo. But if you want to change or replace the tube in an existing compression fitting then you will need to get extra compression sleeves.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

RE: Bowden tube fittings

I’m going to try going the other way.

My compression ring on the extruded end is over crimped and it has narrowed the diameter of the bowden tube.

If The print finishes and I don’t unload/retract it immediately it’s pretty much stuck there until I disconnect the brass connector and cut off the distorted tip of filament clean so it can retract back.

The workaround is to go through the heat up cycle then purge and then it will retract but it all adds time.

I’ve seen a file somewhere that someone drew up a set of adapters to allow Festos to screw into the existing threaded holes on the mini. Can’t find the article or files though.

If anyone has the link let me know please.

RE: Bowden tube fittings

@j-martin

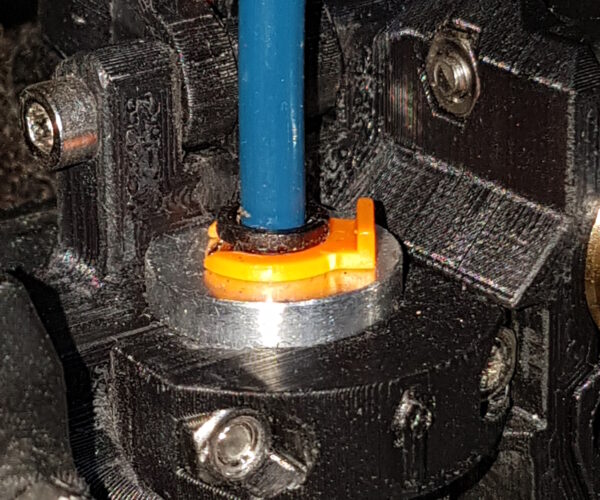

I think this is what you may have seen.

https://www.prusaprinters.org/prints/30001-prusa-mini-pc4-m6-bowden-fitting-adapter

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

RE: Bowden tube fittings

does anyone know how to fix the brass compression fittings to the PTFE? my mini came (yesterday) with one of the fittings loose, so did not make much of printing unfortunately after the 5 months wait... I can use pliers but they will not look pretty... and the initial try to fit the one that was loose with it was not very successful. I would like to fit one of the new ones that come in te spares bag, but would like to know if anyone knows teh appropriate way to do so....

thx a bunch

RE: Bowden tube fittings

@trevino-david

Compression rings compress (tighten) when you screw down the nut onto the seat.

- Place the compression nut on the PTFE tube

- Then place the compression ring on the tube

- Insert the end of the tube into the threaded seat

- Slide the nut down (which will also slide the ring)

- Tighten the nut while keeping the tube pressed into the seat

The tube should now be 'locked' in place. If you unscrew the nut you will find the compression sleeve is now pressed into the tube slightly and will not move.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

RE: Bowden tube fittings

@jasii

That just worked like a charm!! Thanks a lot!! fro the marks in the PTFE tube the compression nut was too close to the end of the tube, now where it belongs, I now only need to deal with the under-extrusion 🙂 already found the thread though.

have a nice day

RE: Bowden tube fittings

@jasii

just as follow up, finally the mail support answered... 🙁

"... We don't have a guide on how to fix the brass stop to the PTFE tube because it is done by a specialized machine. "

🙂

RE: Bowden tube fittings

Hi jasii,

Check out this with 8mm pushfitting:

https://www.prusaprinters.org/prints/36551-mini-extruder-rear-with-8mm-pneumatic

Cheers

RE: Bowden tube fittings

@jens-1

I'm not sure if you're still looking for the brass fittings/olives but I was also curious if I could purchase them separately. After asking Prusa Support about purchasing them and getting the unfortunate reply that they don't sell them, I ended up finding these on Ebay: https://www.ebay.com/itm/10-Pack-Lot-4mm-Tube-Ferrule-Brass-Compression-Sleeve-Ring-Fittings-Coyote-Gear/222107931567?hash=item33b6aa13af:g:tsYAAOSwd3dZaA4~

They were $17.88 (w/shipping) for 10 of them when I bought them so not necessarily the cheapest thing but they do seem to be compatible.

The invoice they sent mentioned they have cheaper prices on their website but I didn't check into that to verify.

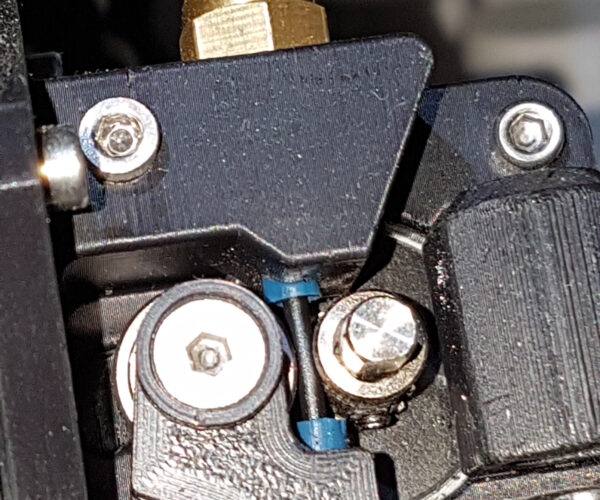

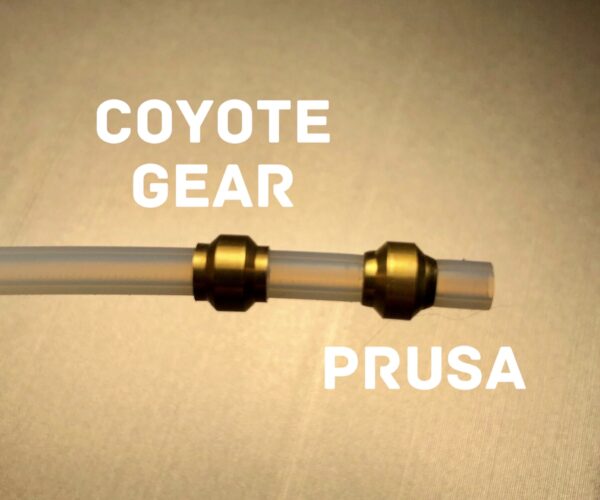

Below is a picture comparing the Coyote Gear and Prusa fitting (note the Prusa fitting is crimped).

RE: Bowden tube fittings

I tried reusing the compression sleeves on some Capricorn tube, but they won't crimp on the tube anymore. I ordered some of the compression sleeves from eBay. Hopefully that will work. Does anyone know if any other fitting will work on the mini?

RE: Bowden tube fittings

OK, this was an extremely early failure that I had with my MINI. I can confirm that the compression fittings, which was already confirmed, that there was some kind of external machine involved with attaching the fitting.

I am thinking that I can model a "compression block" that will achieve this same result, actually. Basically a block-press with a few strong bolts to press the fitting in the same way. (It would take 100% infill, but w/e) It actually looks like the fitting was spun somehow, but I will not speculate further lest I look like an idiot.

Thankfully, I ordered two extra factory PTFE tubes and can take some good measurements! However, I recently convinced myself that the Prusa stock fittings would achieve the same results if you tightened down vanilla compression fittings. I haven't had the need to test that theory, so I haven't.

RE: Bowden tube fittings

The olives (the little compression rings) are nothing special. I just went to my local hydraulic shop and they were about 15c each. They come in multiple sizes so you just need to be sure it’s the right size. In the hydraulics business they are consumable item.

They don’t really require a special tool to crimp them. You just insert the hose with the olive on it into the brass hub and screw it up. When you tighten it up ( pretty firmly) the compression of the hub parts compresses the ring.

But I have to admit it’s a very agricultural method and it’s easy to overcrimp. In the normal usage ( in hydraulics) it doesn’t matter because there’s hydraulic fluid going through the tube and a little over compression makes no difference. But when we try to crimp the olive we are going to pass a solid bit of filament through and even the slightest over crimp is a problem.

I still think a festo is the better method BUT I have had no luck with a festo adapter. I printed up the adapter mentioned above and it works great - for a while, but every one has eventually broken off due to the constant movement of the tubing. Tried them in PLA, carbon fibre, nylon.

RE: Bowden tube fittings

I just installed 2 Pneumatic connector PC4-M8 (thus no adapters needed) replaced the whole bowden-tube from extruder to hotend (3 parts) and running some test prints.

URL : AliExpress

Stock MK4S with FW 6.2.6

RE: Bowden tube fittings

@j-martin

With the original Prusa fittings I always had the problem that the PTFE tube (Capricorn) from the extruder to the hotend came off when printing carbon filament.

Then I installed 2 PC4-M8x1.25 couplings and have had no more problems since then. These also have the advantage that the 4mm PTFE cannot be squeezed in the inside diameter due too high tightening torque of the clamping nut, as can happen with the original ones.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Bowden tube fittings

karl-herbert it seems we have the same supplier 🙂 my CapricornXS will arrive this week, SuperPINDA, next week and I Hope Santa will provide my with a Bondtech extruder.... then there will be nothing for my to complain about 😉

Stock MK4S with FW 6.2.6