RE: Unofficial Prusa Mini Wait Thread

@sm26

I am working on test prints as I type.

--------------------

Chuck H

3D Printer Review Blog

RE: Unofficial Prusa Mini Wait Thread

I know I'm not actually waiting now, having received mine a while back, but I've really only managed to spare about 5 or 6 days to focus on using the MINI since I got it, so this is basically like my first week of use! A couple of months ago I realised it had a problem and I've only just managed to find time in my schedule to resume troubleshooting it.

To recap, when I first assembled the MINI, to test it I printed a 3D Benchy from transparent generic PLA, and later a Marvin from silver grey generic PLA (both the demo Gcode from the USB stick). I wasn't able to get back to it for a while due to other commitments, but as the test prints were perfect I assumed it was working fine. I started using it to print my own things 3 months ago but everything in PLA now fails. It gets a little way into the print - a different position every time - then the filament starts printing out patchy like it's not being pushed out hard enough, then the extruder starts clicking, then it stops extruding at all. Eventually the clicking stops, I presume when the extruder has worn through the entire filament.

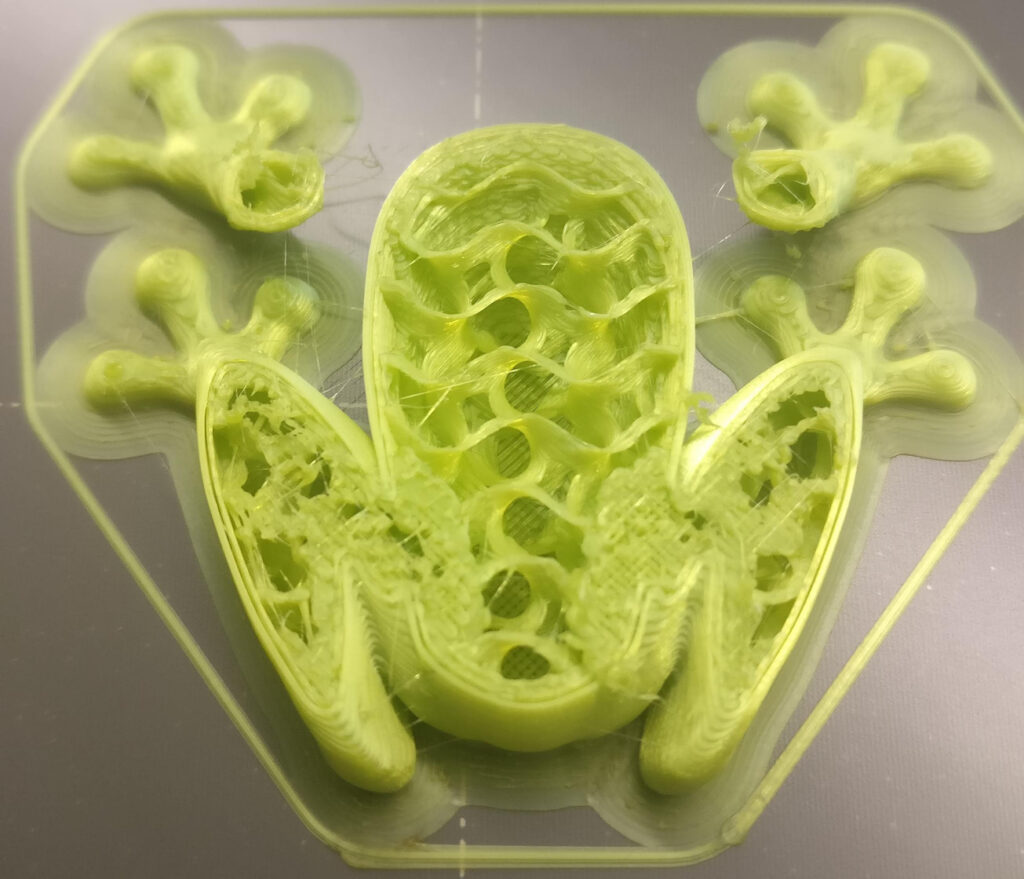

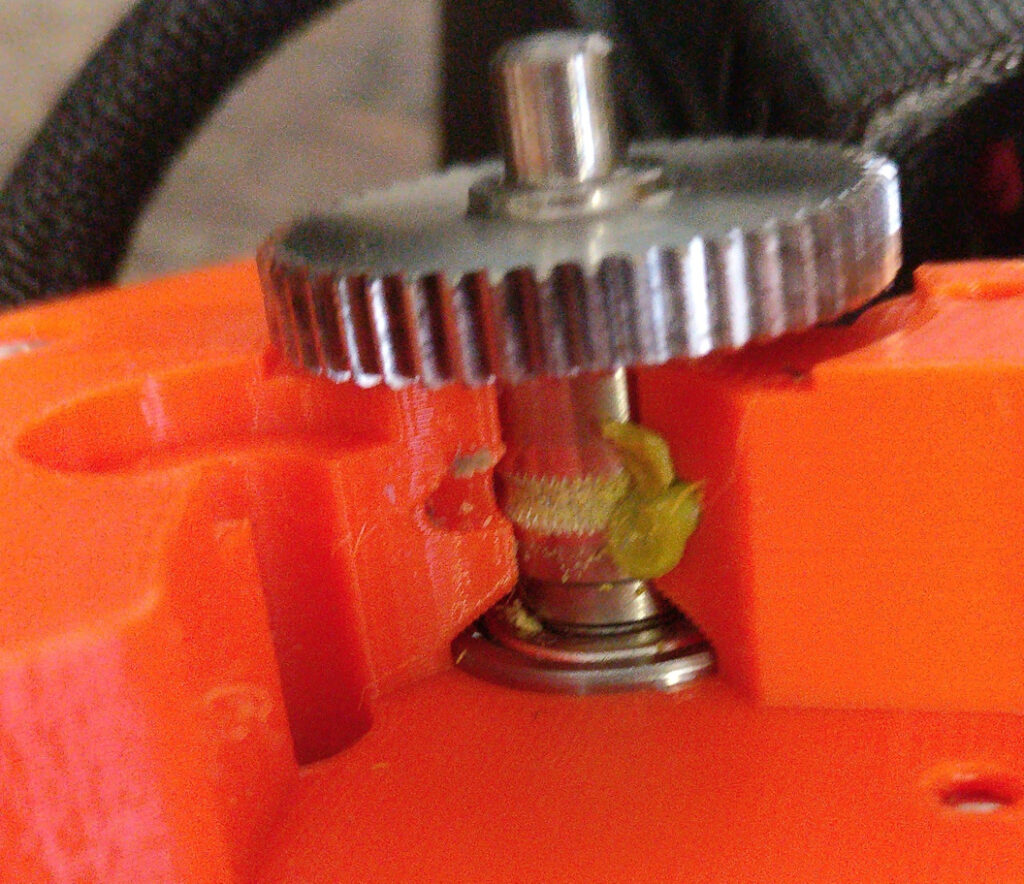

I've tried setting the tensioner to every tension from barely touching all the way to crushing it. I've tried adjusting the hotend temperature in increments up to PETG levels to make the filament less resistant. I've tried repositioning the heat break to the correct position as per the guide. I've tried printing the new revision parts fot the MINI's extruder assembly in case the old versions were the cause of this. I've now even tried using Prusament PLA in the assumption that it might perform better with the stuff it's specifically designed to work with, but the results of my tree frog are terrible, as you should be able to see in the photo below. I came back to it about an hour into the print and it was waving the hotend around with nothing coming out. It looks like it started going patchy at the hind end and then failed completely. The filament was jammed in the extruder section as per the other photo. I did notice the teeth of the extruder gear were full of impacted filament dust, I assume from all the repeated fails, so I've removed these carefully with a dentist pick.

I've noticed that it takes longer to fail when doing objects with fewer retractions or layers at least 0.2mm. I've tried using it to print a simple T shaped block out of ABS and that worked perfectly but I've not tried anything more complex. I'm currently thinking it might be similar to the problem I was having on my MK3S - the filament might be moving through so slowly, the extruder motor is heating up enough to transfer heat across to the Bowden gear, the lower-melting-point PLA filament is lingering in contact with the gear long enough to lose structural integrity when it reverses, then buckling to form a plug at the feed-in end, then resisting being drawn back in causing the extruder to click and slowly grind the filament away. I suppose the only way to tell is to start a print, watch it like a hawk and turn it off the second it starts to misbehave so I can see what the filament is doing at the exact point of failure. It's too late tonight to start looking at it again so I'm going to try again next weekend. As well as inspecting the machine at the instant of failure, I'll see if I can make the same test objects out of ABS to the same detail to see how it handles a material with a higher melting point. I'll also see what a fan on the extruder motor does to the PLA success rate.

RE: Unofficial Prusa Mini Wait Thread

Hello everyone!! My wait is over!! the mini has arrived few hours ago and it's already working!

RE: Unofficial Prusa Mini Wait Thread

@matthewmeek

I'm not sure if this is the same problem, but the shipped mini comes (came?) with the hotend PTFE tube that is some 2mm shorter than it should be. If it moves up (after some time of using) there opens a cavity between the nozzle and the tube that becomes filled with melted fillament that adds a lot of hysteresis to filament movement and in result you get clicking extruder and failed prints.

My father's mini started to misbehave in this way and we were struggling to make it behave, to get any usable print we had to significantly increase hotend temperature. Then I recalled someone had mentioned the same problem months ago in this thread. We replaced the PTFE tube with the spare one (there should be one in the spare part bag) and the printer worked again.

Hope it helps.

RE: Unofficial Prusa Mini Wait Thread

My MINI was shipped midday Friday 8/28 via FedEx and I received it Monday morning 8/31. Pretty good service from FedEx.

Assembly was pretty straight forward and uneventful. No issues on the preflight test, and it came with 4.2.0 firmware installed.

Prusa did release 4.2.1 on 8/31 so I installed that. Tried some of the Prusa supplied prints as well as some I sliced myself. All the prints came out basically perfect.

Tried several prints today and the first layer cal seems to be fine. The MINI fits nicely into my printer shelf.

Pretty satisfied with the printer so far. Hope this continues.

RE: Unofficial Prusa Mini Wait Thread

I'm not sure if this is the same problem, but the shipped mini comes (came?) with the hotend PTFE tube that is some 2mm shorter than it should be. If it moves up (after some time of using) there opens a cavity between the nozzle and the tube that becomes filled with melted fillament that adds a lot of hysteresis to filament movement and in result you get clicking extruder and failed prints.

From what I can see from the specs of the hotend PTFE tube, it should be between 43.30 mm and 43.50 mm. The spare one I have is 43.58 mm (0.08 mm over the maximum allowance) and the one in the MINI is 42.70mm (0.60 mm under the minimum allowance). I wonder if the compression in the system can cause shortening? That said, I did follow the official hotend PTFE tube replacement instructions without changing the tube, moving the hotend up in the heatsink so the existing tube was under compression, as part of my original troubleshooting. I would imagine that as long as the PTFE tube is compressed between the hotend at the bottom and the retention nut at the top, the length of the actual tube isn't absolutely crucial. The net result was my Z-adjust for first layer calibration went from -0.700 to about -1.200 but prints still failed. I'll try changing to the spare as a next step but I suspect I'll need to try the other things as well.

RE: Unofficial Prusa Mini Wait Thread

Aaaand the wait time begins again. Ordered two additional Minis because i'm really happy with my first one (prints since about a month nearly 24/7 - mostly PETG). And because i will take my MK3S out of the printing farm and use it more for private purpose. For me the prusa mini is the perfect Farm Printer. It's quick, reliable and hopefully soon directly controllable through Ethernet. At the moment i have to use an Octopi.

RE: Unofficial Prusa Mini Wait Thread

@riokatlp

I will probably buy another 2-3 also. I currently have another MK3s on order. That will bring me to 7 MK3s and 2 Minis. I have purchased 2 other Mk3s that I build and planned to keep bur sold to friends after offers I could not refuse.

--------------------

Chuck H

3D Printer Review Blog

RE: Unofficial Prusa Mini Wait Thread

My wait is soon over 😍 Just received shipping confirmation for my order I made on June 25th. Back then the estimate was "Late September".

Can't wait to actually start printing stuff without worrying too much (after fighting ~2 years with a 150€ Chinese thingy).

RE: Unofficial Prusa Mini Wait Thread

Can't wait to actually start printing stuff without worrying too much (after fighting ~2 years with a 150€ Chinese thingy).

This is the same situation for me! Mine was so bad I tried to do the bear upgrade but it couldn't even print it's own parts well enough so I gave up and ordered the mini. Maybe I'll eventually finish off the bear upgrade on the previous clone with the mini being able to print its parts!

Ordered on the 12th July, still waiting for email update though.

RE: Unofficial Prusa Mini Wait Thread

@arto

I have two Chinese thingys. They do work . I enjoy the tinkering part of them. But now I gotta get something reliable and sturdy. Starting to get more order then my Chinese thingys can handle lol

RE: Unofficial Prusa Mini Wait Thread

@riokatlp

I will probably buy another 2-3 also. I currently have another MK3s on order. That will bring me to 7 MK3s and 2 Minis. I have purchased 2 other Mk3s that I build and planned to keep bur sold to friends after offers I could not refuse.

I decided against another MK3S and for the Minis. Print time is just way faster for me. And i can place them neatly within an Ikea KALLAX 🙂

RE: Unofficial Prusa Mini Wait Thread

The wait is over, ordered 10th July, delivered 4th September.

On my 5th print now, so far so good.

Sample filament was: Prusament, Galaxy Black (I already have a roll of this), and Opal green.

RE: Unofficial Prusa Mini Wait Thread

@chillygeo

They are pumping these are pretty quickly then. Getting excited just waiting for mine

RE: Unofficial Prusa Mini Wait Thread

I'm not sure if this is the same problem, but the shipped mini comes (came?) with the hotend PTFE tube that is some 2mm shorter than it should be. If it moves up (after some time of using) there opens a cavity between the nozzle and the tube that becomes filled with melted fillament that adds a lot of hysteresis to filament movement and in result you get clicking extruder and failed prints.

[Essay truncated] ...I'll try changing to the spare as a next step but I suspect I'll need to try the other things as well.

Thanks for the advice, it seems that was exactly what was wrong with it. I suppose I must have re-fitted the old one poorly, or perhaps I couldn't see the silver PLA stuck inside the PTFE gap on the metal hotend. But with green PLA I could see it quite clearly around the rim where the PTFE should sit. I followed the debris extraction guide in the online manual, and... made it a lot worse. So I picked the soft PLA out with a thin metal rod while the hotend was on full heat. Since then I've tested it on the demo Prusa logo (quick and easy), the tree frog (more challenging), a bunch of face mask strap holders (I needed one, thought I might as well make some for others as well), and what I considered the ultimate test - The Arcane Miniatures Skies of Sordane Warforged Artificer they were giving away during their Kickstarter a while back. I've never quite managed to complete it due to the complexity, but the MINI just made it at 0.05mm layer detail with no problems. Removing all the supports destroyed the sword and half snapped his left hand off, but it's still unbelievably detailed for a non-resin print.

I wonder why they have been leaving the factory with the PTFE tube uncompressed?

RE: Unofficial Prusa Mini Wait Thread

Posted by: @matthewmeek

Thanks for the advice, it seems that was exactly what was wrong with it. I suppose I must have re-fitted the old one poorly, or perhaps I couldn't see the silver PLA stuck inside the PTFE gap on the metal hotend. But with green PLA I could see it quite clearly around the rim where the PTFE should sit. I followed the debris extraction guide in the online manual, and... made it a lot worse. So I picked the soft PLA out with a thin metal rod while the hotend was on full heat. Since then I've tested it on the demo Prusa logo (quick and easy), the tree frog (more challenging), a bunch of face mask strap holders (I needed one, thought I might as well make some for others as well), and what I considered the ultimate test - The Arcane Miniatures Skies of Sordane Warforged Artificer they were giving away during their Kickstarter a while back. I've never quite managed to complete it due to the complexity, but the MINI just made it at 0.05mm layer detail with no problems. Removing all the supports destroyed the sword and half snapped his left hand off, but it's still unbelievably detailed for a non-resin print.

I wonder why they have been leaving the factory with the PTFE tube uncompressed?

Glad to help. All the time, it felt like the hotend is not getting hot enough. What made the debugging worse was that increasing the temperature almost solved all problems. We even replaced the thermistor -- to no avail.

I've also bought a spare tube (forgetting there was an extra in the spare part bag) as well, vaguely remembering someone had mentioned it in this forum. But it seemed like there is no cavity in the hotend. It looked clean. Only when I replaced the tube as a last resort it miraculously started to work again. *shrug*

I have no idea why the installed tube is too short. It is even more mysterious since the extra one in the spare part bag provided with the printer as well as the spare part sold in the Prusa eshop have both the right dimension.

Forgive me my sarcasm but it almost feels like the proverbial "screw-up-part" that every device has (allegedly!) installed inside, waiting to ruin the device just day after the warranty period is over (AKA planned obsolescence). I hope it's just something mundane, like effed-up cutting template/jig at the hotend completion workstation.

Anyway, I'm amazed with the detail of the printer too.

RE: Unofficial Prusa Mini Wait Thread

I am working on the bed alternative shootout.

--------------------

Chuck H

3D Printer Review Blog

RE: Unofficial Prusa Mini Wait Thread

While you wait, I recommend you order some silicone socks to keep your heatblock and nozzle clean. Bulrolls 2 silicone socks for $7.

--------------------

Chuck H

3D Printer Review Blog

RE: Unofficial Prusa Mini Wait Thread

While you wait, I recommend you order some silicone socks to keep your heatblock and nozzle clean. Bulrolls 2 silicone socks for $7.

Thanks for the heads up, ive just ordered a couple.

RE: Unofficial Prusa Mini Wait Thread

@charles-h13

Funny thing is I did this like 3 days ago. Silicone socks extra ptfe tunes,extra nozzles. Anything else?