Experiences with PC Blend and Mini?

Hello,

has anyone already tried the new Prusament PC Blend on the Mini?

I would love to be able to print with PC reliably on my Mini.

So can you print big things out of PC (or only small)? Whats ur generell experience with this Filament?

Thanks!

RE: Experiences with PC Blend and Mini?

I've printed a small fan shroud which turned out pretty well using the smooth PEI sheet and provided Glue Stick. I had no issues printing the small shroud without an enclosure. I would suggest printing a skirt as high as the model to help prevent unwanted drafts, you can actually see the ASA Prusament Blog post for information on how to do that: https://blog.prusaprinters.org/asa-prusament-is-here-learn-everything-about-the-successor-to-abs_30636. Otherwise, the tips and tricks in the PC blend post were helpful too.

Large objects would be more problematic however since the Prusa MINI heatbed only goes up to 100C, 110C would provide greater adhesion to the build platform.

RE: Experiences with PC Blend and Mini?

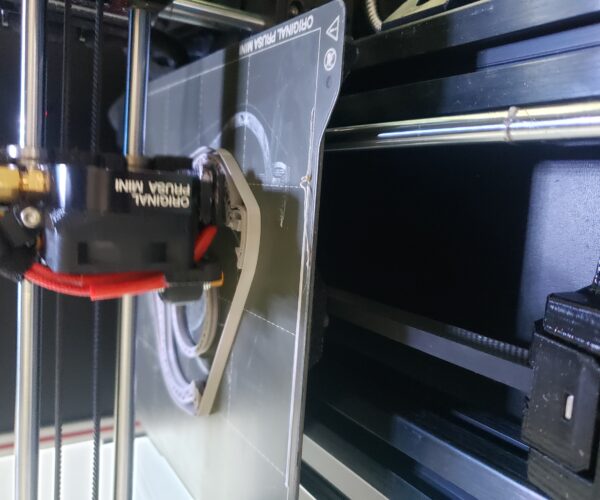

I just started printing with the Prusament PC Blend in the last few days. It is printing great and I am doing large, long prints(one was over 13hrs)

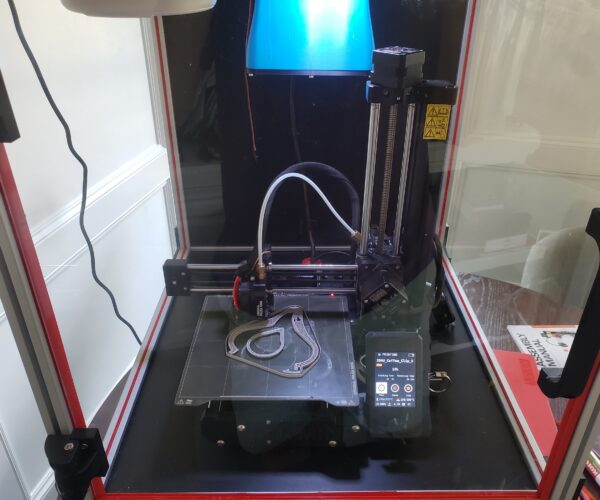

I did encounter the known extrusion jamming issues associated with the well documented shrinking bowden ptfe tubes when printing ASA at 265C. I replaced the prusa ptfe bowden tubes with Capricorn XS low friction ptfe tube at a length of 45.4mm. I have had no issues with jamming since then and I am now printing with prusament PC blend for over 8 hr prints at 275C. Even with an enclosure at 100F a skirt the height of print is required. Otherwise large prints will lift off the build plate. I have been using the smooth pei plate with the supplied glue stick without any problems.

I'll try to post pics of the prints, enclosure and temps I am using. Everything besides the pfte bowden tube is stock and i am using the stock prusa slicer prusament pc blend settings.

RE: Experiences with PC Blend and Mini?

Thanks for this very useful post. I'm currently using PETG, but intend to shift at least partially to PC Blend, and on some parts I go for PCCF from Prusament. So I need Capricorn tubing in addition to hardened nozzle. Both are easy to come by, likely I'll try E3D's V6 Nozzle X as a nozzle.

One would have thought that enclosure at those temperatures would have helped.

RE: Experiences with PC Blend and Mini?

I don't really understand how humidity is measured and even the significance of relative vs. absolute but as most sensors seem to measure relative surely 35 @ 100F (F ???) seems very high.

RE: Experiences with PC Blend and Mini?

I've printed a small fan shroud which turned out pretty well using the smooth PEI sheet and provided Glue Stick. I had no issues printing the small shroud without an enclosure. I would suggest printing a skirt as high as the model to help prevent unwanted drafts, you can actually see the ASA Prusament Blog post for information on how to do that: https://blog.prusaprinters.org/asa-prusament-is-here-learn-everything-about-the-successor-to-abs_30636. Otherwise, the tips and tricks in the PC blend post were helpful too.

Large objects would be more problematic however since the Prusa MINI heatbed only goes up to 100C, 110C would provide greater adhesion to the build platform.

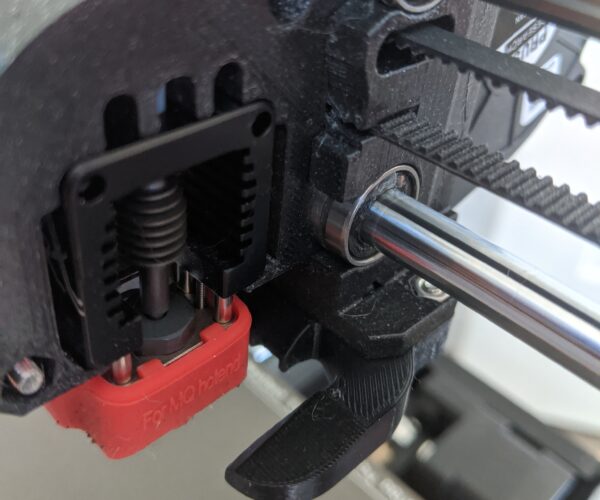

Did you make that sock yourself?

--------------------

Chuck H

3D Printer Review Blog