RE: Printing TPU on the MK4

The Amazon listing doesn't specify the shore harness.

On the Amazon description 95 shore are mentioned.

RE: Printing TPU on the MK4

The Amazon listing doesn't specify the shore harness.

On the Amazon description 95 shore are mentioned.

We must be looking at different listings. The Amazon listing I see (linked below) doesn't specify the shore hardness. There is a "customer question" and "customer answer" that says 95, but that is just another customer guessing at what it is.

https://www.amazon.com/gp/product/B088962DCK

Is that a different listing from the one you are seeing?

RE: Printing TPU on the MK4

https://www.amazon.de/gp/aw/d/B088962DCK?psc=1&ref=ppx_pop_mob_b_asin_image

RE: Printing TPU on the MK4

https://www.amazon.de/gp/aw/d/B088962DCK?psc=1&ref=ppx_pop_mob_b_asin_image

Interesting - that listing (Amazon.de) is quite different and more detailed than the US listing (Amazon.com)! But presumably the same product. Thanks for the info!

RE:

Hi! I have good news, I dryed my TPU and can confirm a perfect printability of 85 shore A TPU!

Before sharing my profiles, here some tips I learned with my MK3s:

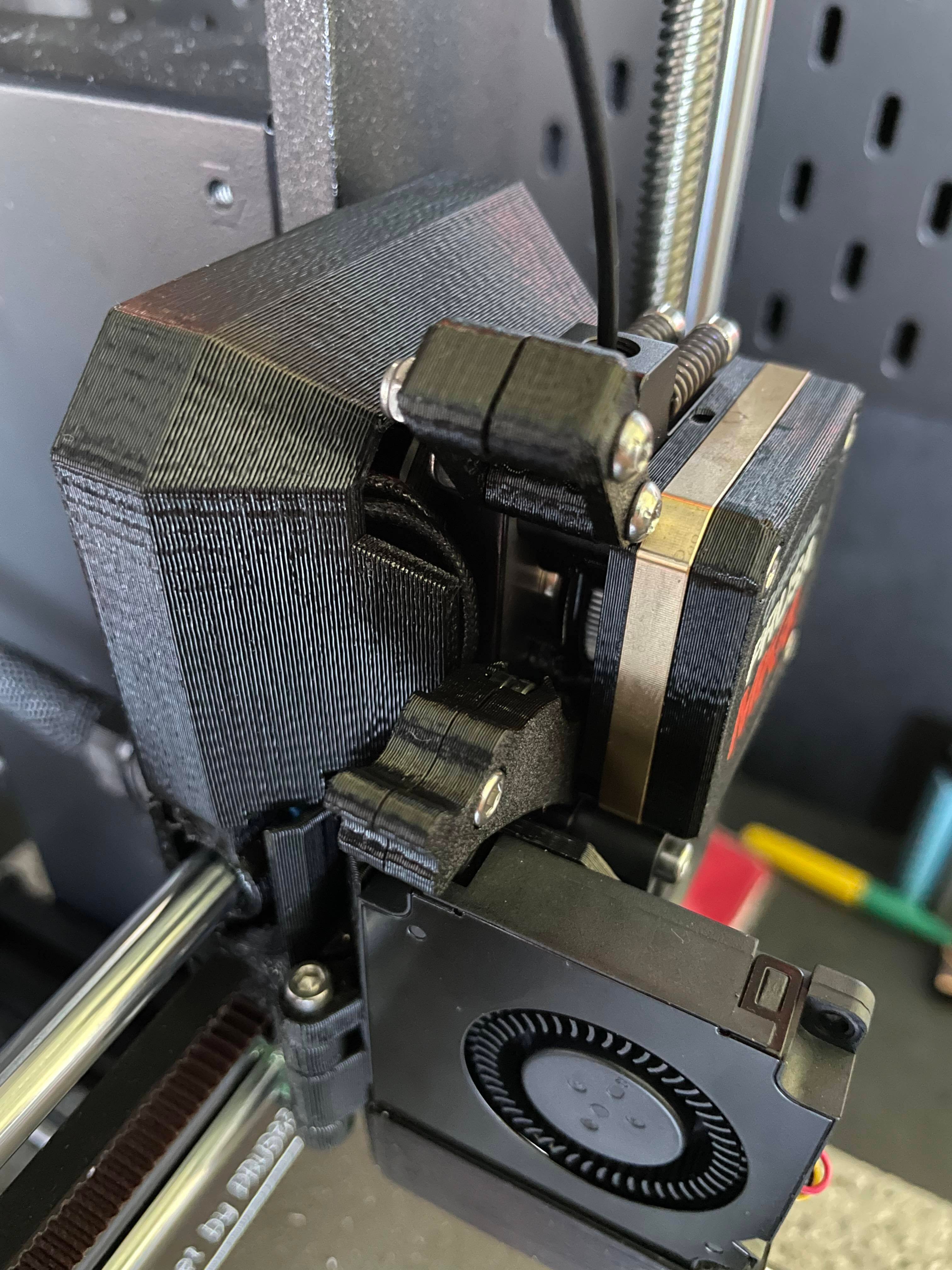

- Most important tip: do not let the automatic loading of your Prusa guide the filament through the print head. I always disconnect the idler, pass the filament through the filament detector but not further! I let the printer ask me if the loading is ok to press Yes and then I manually push the filament to the nozzle. Then I release the two screws that control the iddler tension until the springs are barely touch both sides (screw and plastic part) and close it.

- I just confirmed it: don't hesitate to dry your TPU. This kind of polymer is really hydrophilic, so it may quickely absorb water resulting in an inconsistant feeding and a lot of bubbles.

- Use really slow speed (depending on the hardness of TPU): the lowest the best if you want to be sure that it will not be pushed behind your extruder gear.

- One of the most important thing about flexible filaments is the brand you choose. In effect, those kind of filaments are way more difficult to produce than standard high rigidity thermoplastics. Elasticity and softness are two factors that are difficult to master when you extrude and want consistent diameter. I know Ninjatek is one of the most known manufacturer, but by experience Ninjaflex isn't the easiest filament to print (compared to others brand with similar hardness).

I personnaly use a French brand (Arianeplast) who makes 85A TPU that can be printed perfectly.

https://www.arianeplast.com/245-tpu-shore-85a

That's it!

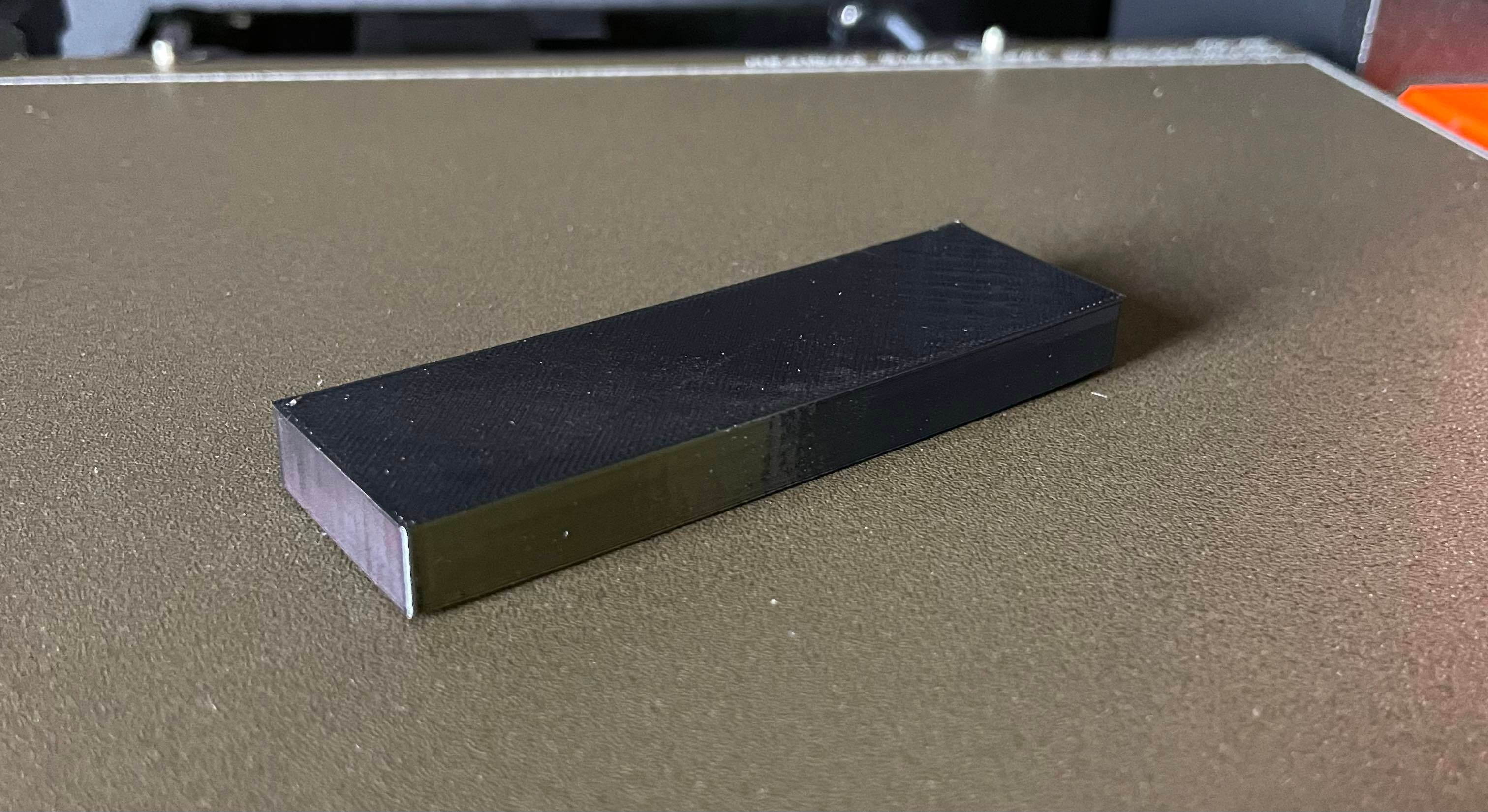

Result:

Before (left) and after (right) drying of the filament: HERE

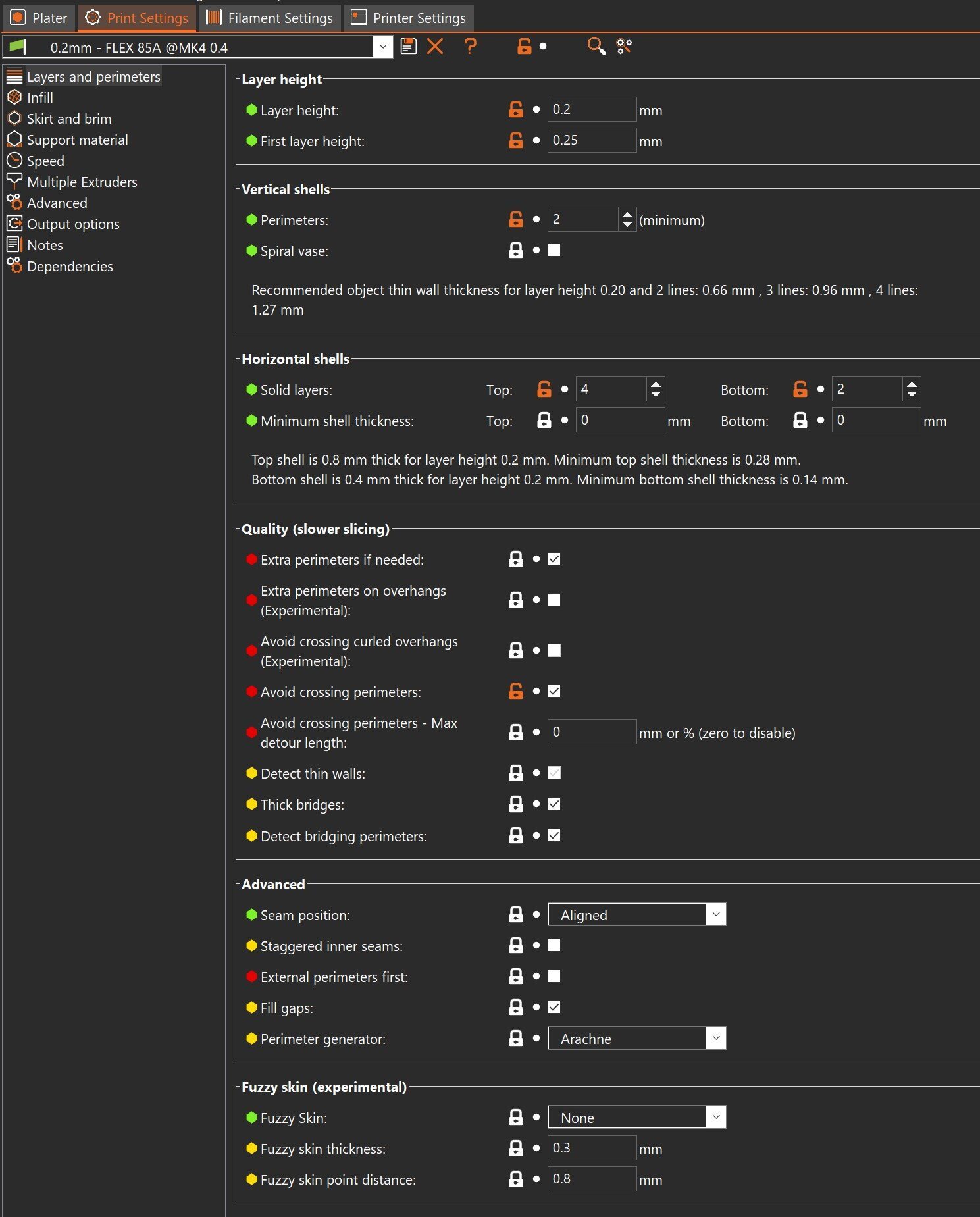

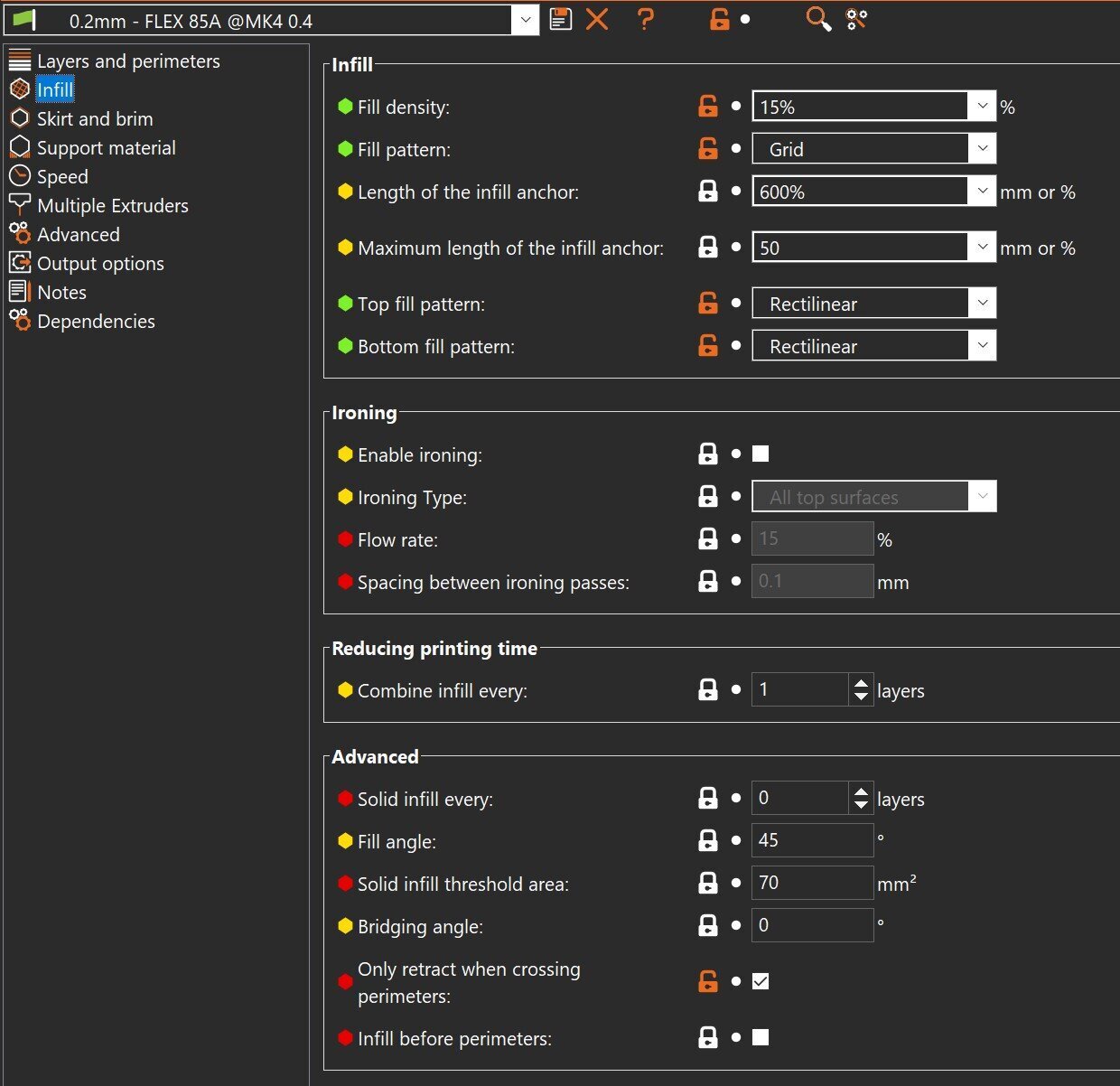

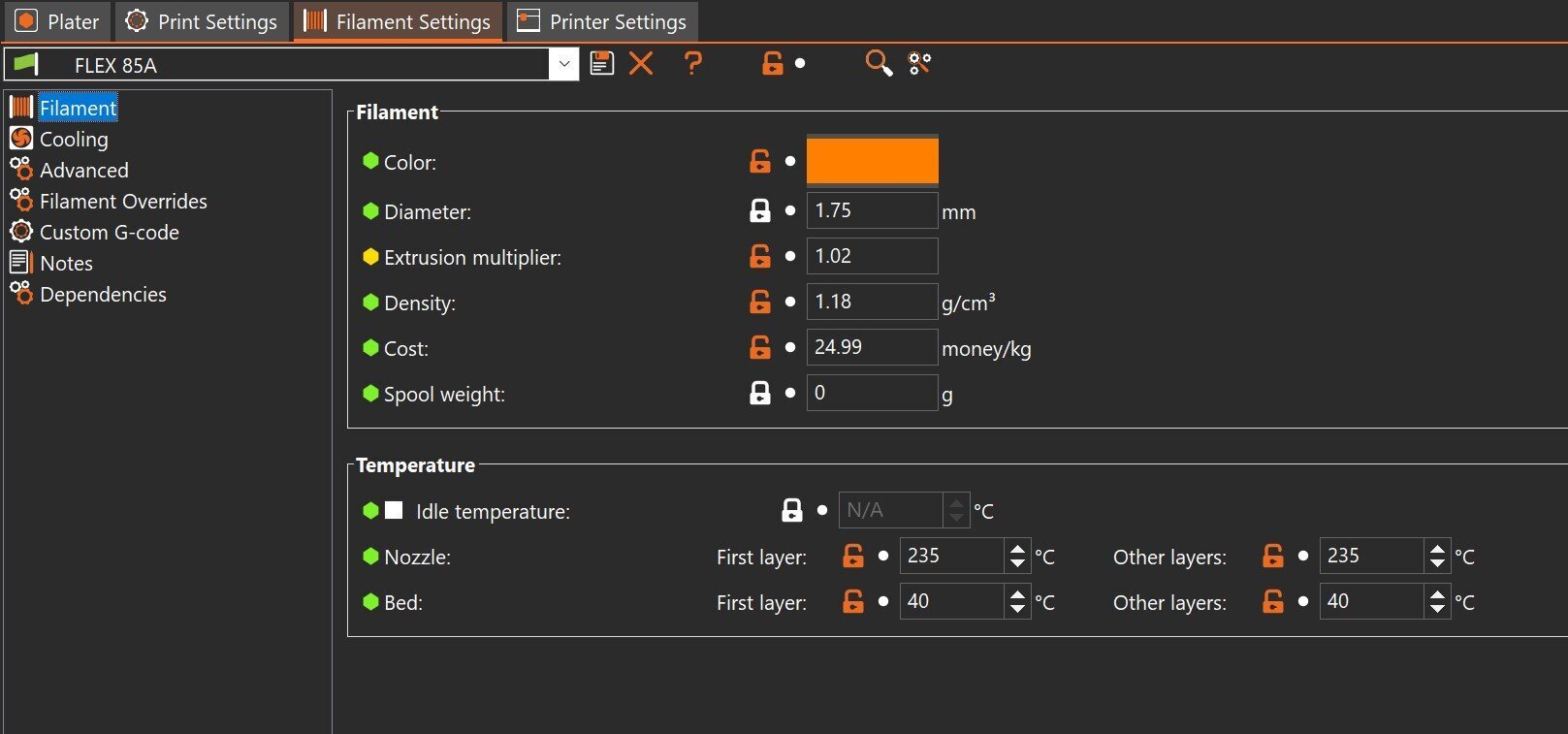

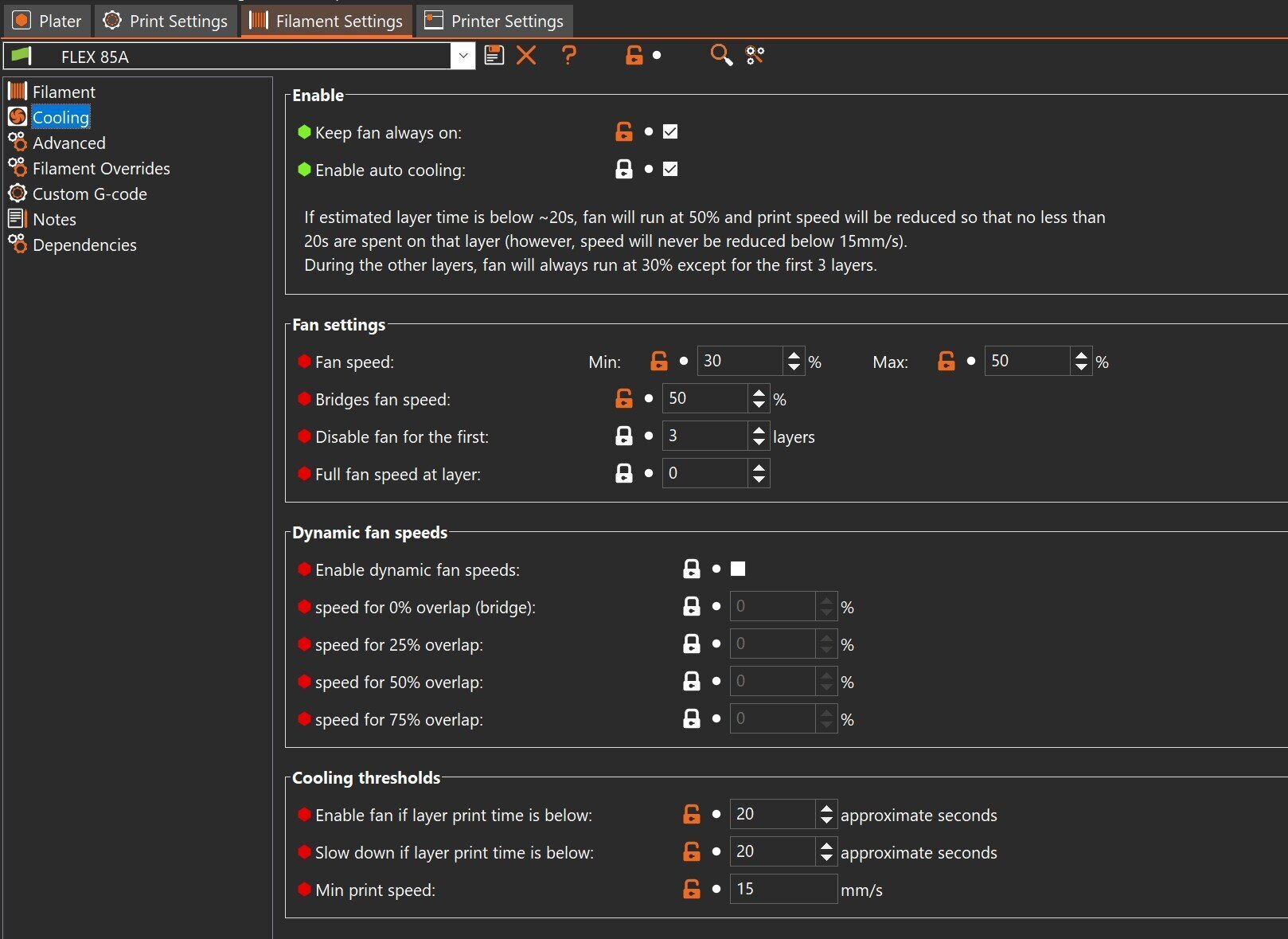

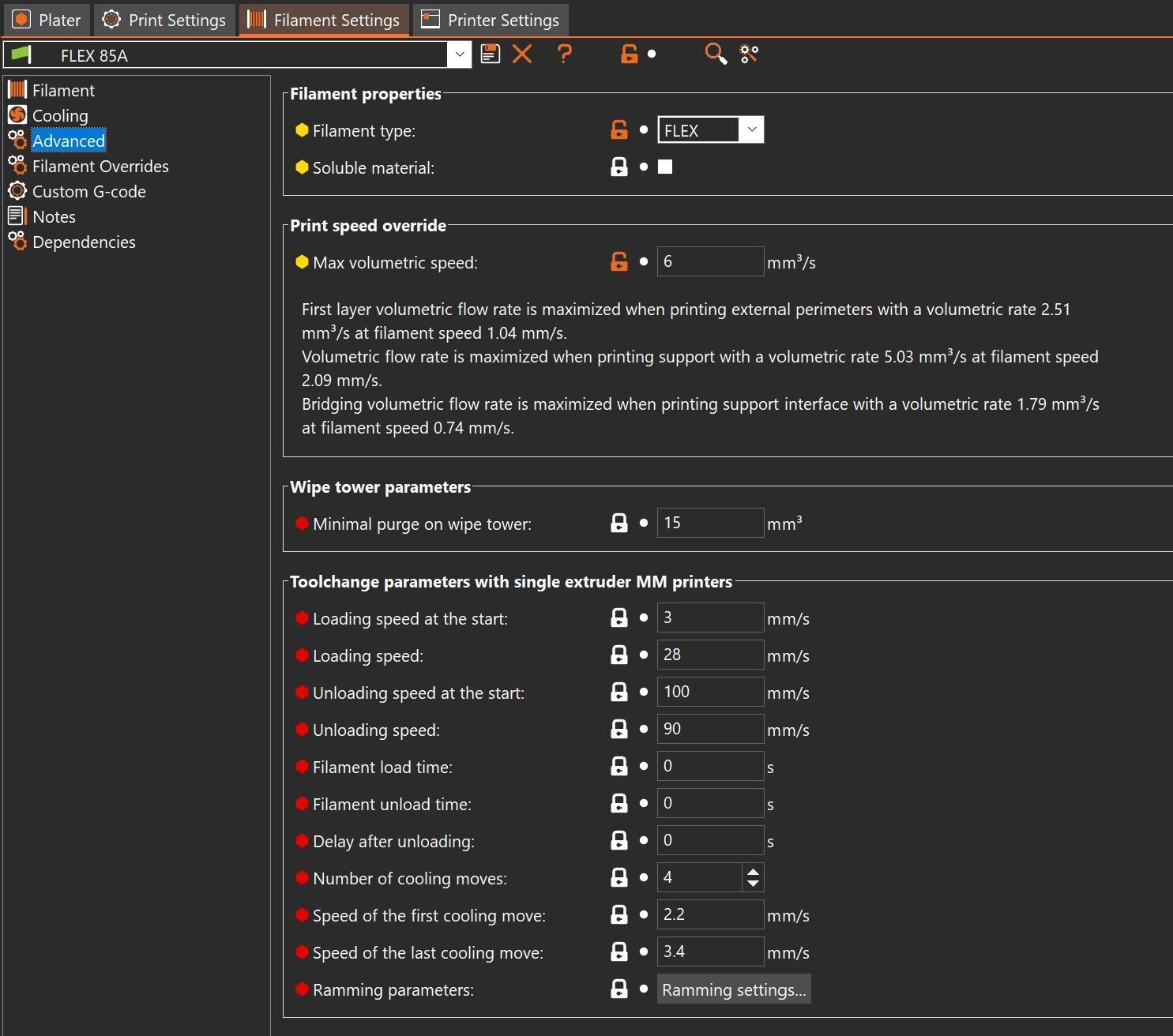

Here are the different parameters I used, based on a preset profil I found for my MK3s (for a 82A TPU)

RE: Printing TPU on the MK4

Here are the different parameters I used, based on a preset profil I found for my MK3s (for a 82A TPU)

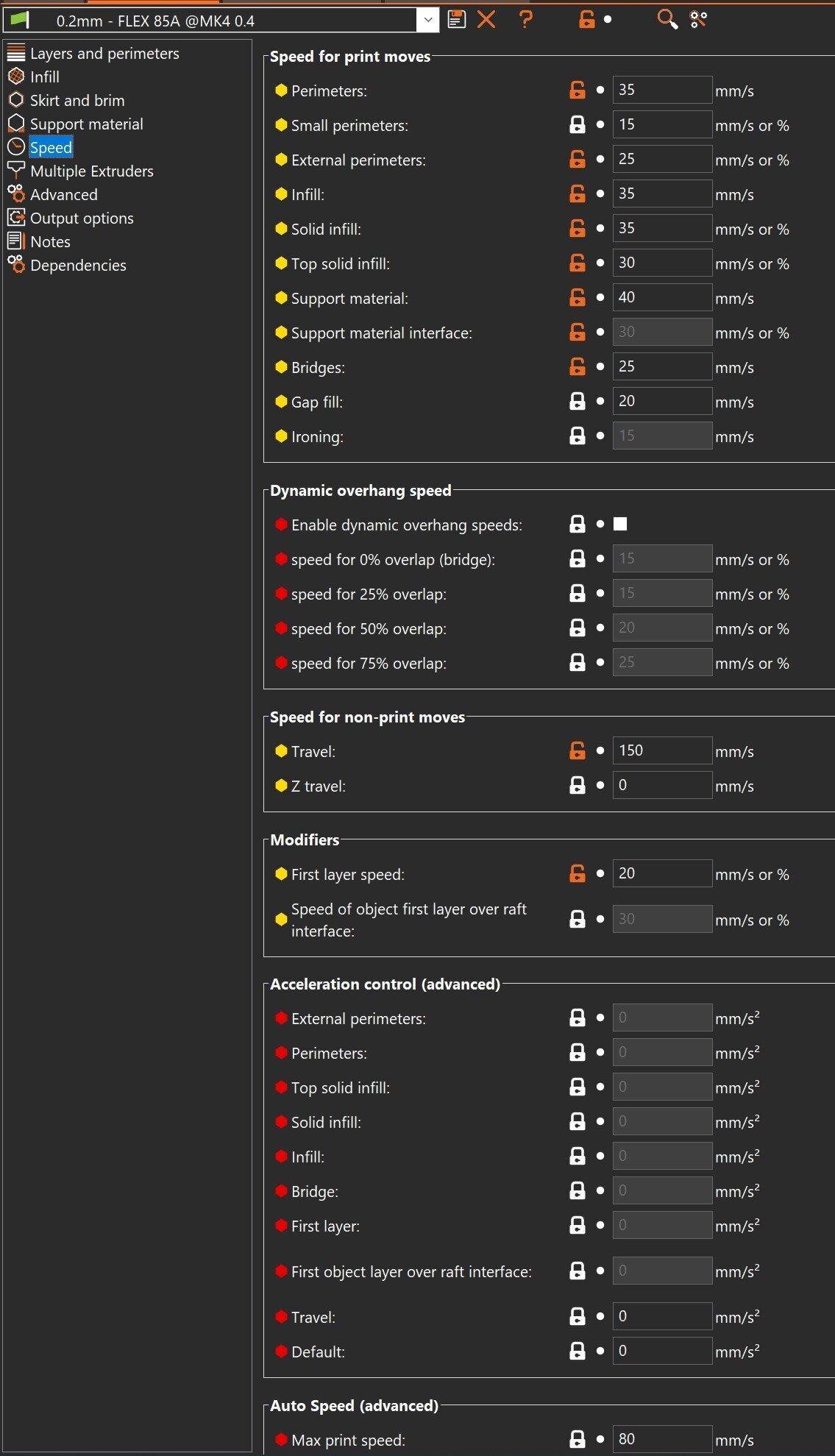

Thanks for all the info! Can you add a snapshot of the "Print Settings, Speed" parameters page?

RE: Printing TPU on the MK4

Oh crap sorry, I was sure I had one...

Here it is:

RE: Printing TPU on the MK4

Here it is:

Thanks! I see you have Max Volumetric Speed set at 6, but then have various print speeds (perimeters, infill, etc) manually slowed down. I went the other route -- just lowering Max Volumetric Speed and letting PrusaSlicer lower the speeds as/where needed.

What actual volumetric flow rate are you hitting during the print? (In the sliced object view, change the view dropdown to "Volumetric flow rate" and then use the layer slider to scroll through the layers.)

RE: Printing TPU on the MK4

When I printed the box I hit about 3 mm3/s on infill.

RE: Printing TPU on the MK4

When I printed the box I hit about 3 mm3/s on infill.

That matches with what I was using for the 85A... At MVS 3.0 I got reliable prints, but at 3.5 I had jamming. I did not try values between 3.1 and 3.4 to find the actual "threshold" were jamming started, as I was happy with the results at 3.0.

RISPONDI: Printing TPU on the MK4

I tried to A95 TPU LITE printing, disaster, clicking sound inside the Nextruder and extra filament in there.

Is my error maybe to have started to wrong filament preset to generate mine?

Which could it be a good Prusa Slicert preset for A95 TPU material + input shaper fw printing?

Of course I tried 30mm/s oltre 50mm/s speed, 220 or 230°C, 0.5mm or 1mm retraction ..same bad result.

No probs printing with PLA or pre foamed PLA I use most.

Any suggestions or experience on this TPU issue?

Thanks all!

RE: Printing TPU on the MK4

I have attached a small print project that I did with SainSmart TPU (A95). I modified the speeds from the default profile for SainSmart TPU that is included with PrusaSlicer to have all the same value. I used the printer profile without input shaping. The part I printed is small so speed is not such a big factor and I think that input shaping can cause trouble with TPU which does not like sudden acceleration and tends to clog then.

RE: Printing TPU on the MK4

Jams with TPU happen because the filament is being fed faster than it can be melted -- leading to compression and bending/buckling above the melt zone. The best way to avoid that is to lower the "Maximum Volumetric Speed" in the slicer. That will let the slicer automatically lower speeds everywhere needed (and not lower them where not needed).

Attempting to change all the individual speeds (i.e., perimeters, small perimeters, external perimeters, infill, solid infill, etc., etc.) is an antiquated approach and way more error prone. Modern slicers will automatically limit all those speeds, where/when needed, if you just set the proper max volumetric speed (mvs). In PrusaSlicer, that is on the "Filament Settings" tab under "Advanced".

For A85, start with one of the Prusa templates or generic TPU profiles, then set an MVS of about 3.5. If that solves the jams, you may be able to increase MVS a bit for that filament; if there are still problems, lower it a little more.

I tried to A95 TPU LITE printing, disaster, clicking sound inside the Nextruder and extra filament in there.

Is my error maybe to have started to wrong filament preset to generate mine?

Which could it be a good Prusa Slicert preset for A95 TPU material + input shaper fw printing?

Of course I tried 30mm/s oltre 50mm/s speed, 220 or 230°C, 0.5mm or 1mm retraction ..same bad result.

No probs printing with PLA or pre foamed PLA I use most.

Any suggestions or experience on this TPU issue?

Thanks all!

RE: Printing TPU on the MK4

So, once loaded and started from correct filament preset, no need to reduce all printing speeds (in my case I see default 170mm/s) at 50mm/s or so, since they will be anyway reduce to guarantee the max flow in the preset, correct?

What about transfer speeds? In material specs I see it's suggested 100m/s, default is more (300ms)..

Thank you!

RE:

Looks good! I can't see the top surface very well, but that roughness could be over- or under-extrusion so you might experiment with changing the extrusion multiplier by 5% lower/higher. That roughness (and some of the stringing) might also be damp filament if you haven't dried it (dry at 50C for ~4 hours).

RISPONDI: Printing TPU on the MK4

Ok, so filament is dry.

With more/less 5% extrusion multiplier you mean MVS value?

Thanks

RE: Printing TPU on the MK4

With more/less 5% extrusion multiplier you mean MVS value?

No, the extrusion multiplier can be found on the "Filament Settings" tab, under "Filament"; third item on that page is "Extrusion multiplier." It is common to use a high value there for TPU, typically 1.1 or even 1.15 (which would be 110% or 115%). If your print appears to have too much material (i.e., top is rough because nozzle is digging into it during print), then try lowering it by 5 or 10%. If it looks like there isn't enough material (i.e., top is rough because there are gaps), then try increasing by 5 or 10%.

RE:

Ah ok, interesting.

Will give it a try next time I'll print TPU and report back.

Thank you!

RE: Printing TPU on the MK4

Greetings all. I recently assembled my MK4 and have been pleased with the results until recently. I am printing multiple identical parts with Flexfil 98. Initially, I was able to print two parts on one plate and then I started getting filament jams. I went to 1 piece per plate and it started working again, but now has started jamming again 30-50% of the way into the task. I use the default slicer settings but don't understand why performance has degraded. I total I have printed 80 pieces or so. TIA,

Joe