Multiple sheets and LiveZ

In my mk3, I used the 3 different sheets, I added profiles for each, and could then adjust for petg and pla, for the sheets, where pla can be closer to bed than Petg, due to petg doesn't like to be squished so close to the bed.

But on mk4, it does everything automatically, and works flawlessly on all 3 sheets, but I have only used PLA so far, though, on the Satin sheet, I would want the printer to print a bit closer to the bed.

But since it uses an loadcell, and doesn't (to my knowledge) have sheet profiles, then I cannot adjust it closer for the satin sheet, since that will also make it closer to the smooth and txt sheet, right?

And especially for PETG, how do I adjust for different z there? (or, since I choose petg in the printer, does the printer know that it should not go so close?, or that livez adjustments will be stored for PETG?)

I think I found some tuning options for livez, but not dared to test it yet, since I think that will change printing for all sheets.

RE: Multiple sheets and LiveZ

The MK3 pinda senses the metal core of the build plate. The MK4 senses the surface of the build plate.

Smooth pei has 3m adhesive sheet between it and the build plate and this makes it thicker than powder coat on the textured or silk build sheet. On the MK3 you have to adjust look liveZ to compensate for the surface thickness that the pinda can't see. The MK4 load cell should 'feel' the surface of any build plate, without adjustment

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Multiple sheets and LiveZ

yes, and that works kinda ok, but on the mk3, I had to have different LiveZ for the same sheet, when I printed with PLA or PETG, so when they added sheet profiles I could store satin-pla and sating-petg.

But when I now printed same objekt on all three sheets, PLA only so far, then I see the nozzle lines on the print from satin sheet, but not on the textured sheet. On the mk3 I had adjusted so the nozzle lines was invisible on all sheets.

It would be nice with same on mk4, but I guess Prusa give some, and take some? 😉

RE: Multiple sheets and LiveZ

Sadly, it doesn't "feel" correctly, as it only tests once at the touch point rather than "feeling" around that point and averaging the result. For the textured plate this is important, because the nozzle can drop into a texture gap or sit on a high point in the texture. I am having mixed results with the same printed part, some good and others detaching, and the latter showing signs of a poor first layer. Z-adjust is essential but the inconsistency still exists.

See my posts in the MK4 First Layer Issues ksection.

RE: Multiple sheets and LiveZ

Ok, similar problem as yours I think, on my mk3 I newer had lift on my satin or txt sheet when printing with PETG, printed two prints yesterday, one on each sheet. on the txt sheet it liftes straight away, on the satin sheet, I added helper discs, and it still lifted (super simple print, box without bottom), so both my prints have wobbly bottom and wont sit straight. Think I need to find a place to run my mk3 to be able to do these prints, until I find out how to tune mk4 correctly.

I'm going to print a full single layer sheet on mk4 to see how good it is, on my mk3 that is flawless, gives me one nice printed sheet with no holes, no visible lines from the nozzle etc (both with petg and pla).

I wonder how this will be on the xl when it finally shows up.

RE: Multiple sheets and LiveZ

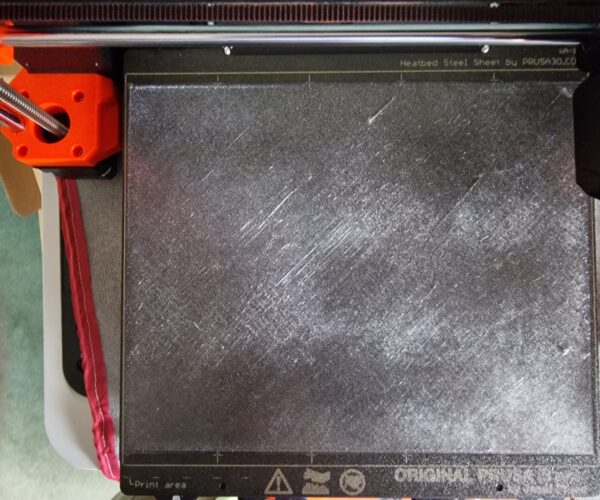

I've done two full bed prints and several short corner prints with one layer. I used Z-height adjustments to determine a suitable setting for the prints and set it to perform the effect of slight over-extrusion, so that hedging shows high areas. Ignore the stringing and blobs that are a product of nozzle pickup from the hedges. There are clearly zones of unevenness as can be seen, and I overlaid one of the prints on the bare heated bed (not printed on it!!!) to see if there was any correlation to the fixing etc. In doing this I noted a manufacturing issue with the silk screen printing; there is an unevenness in the ink height on my bed that lifts the sheet along the right-hand side. OK, the auto-levelling should address this, but it leaves some flexure in the sheet that the leveling may compress, giving an error. It's all conjecture at the moment, but the MK3 heated bed is flat. More investigation is required.