MK4 upgrade printable parts PETG vs PLA

So, Prusa recommends PETG for the printable parts, which I understand for things around the nozzle or the bed since it's more heat-resistant than PLA. However, all the other parts - like stuff that holds cables together, or enclosures for LCD, PCB, etc... is there any reason to not print them in PLA?

You may get away with printing quite a lot in PLA. For Prusa the logistics of tracking which machine is printing what when the next batch is needed probably make all-the-same simplicity worthwhile.

Cheerio.

RE: MK4 upgrade printable parts PETG vs PLA

You may get away with printing quite a lot in PLA. For Prusa the logistics of tracking which machine is printing what when the next batch is needed probably make all-the-same simplicity worthwhile.

Cheerio.

That was my assumption. Thanks!

RE: MK4 upgrade printable parts PETG vs PLA

If all you ever want to do is print PLA, printing parts in PLA (with the exception of around the hotend) may be okay.

RE:

Printing printer parts in PLA is rarely a good idea and that is not even about the relatively low heat resistance but about creep. PETG shows way less creep than PLA in the long run. PLA parts flex less than PETG but they do sag over time, substantially in fact. It doesn't matter what PLA you use, some special high temp PLA, regular PLA, cheap or expensive. I have yet to see a PLA which doesn't creep a lot over time.

There is a good reason Prusa doesn't print any pieces in PLA.

An exception are parts that are entirely uncritical from a mechanical point of view. The LCD cover for example should be fine, as it won't make a difference if it sags a bit over time. Just ask yourself if it matters if the part distorts slightly over time, if it doesn't you should be fine with PLA.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: MK4 upgrade printable parts PETG vs PLA

The electronics might get too warm for PLA as well and could cause deformations there. And the fan shroud is to be printed in ASA, not PETG. All parts that are in contact with the motors will get a bit too hot for PLA as well. I would not bother with PLA for printer parts, as PETG is so easy to print and better safe than sorry. With ASA/ABS you are more likely to run into problems with warping (and unpleasant/harmful evaporations), but not for PETG.

RE:

^^ If you want to print some ABS like material that doesn't warp at all (even less than PETG) try TitanX. It is a heavily modified ABS which behaves very similarily to regular ABS but is printable even without enclosure (even though enclosure is preferable for better layer adhesion). I do agree however that for the Mk3/4, except for the fan shroud PETG should do and is almost as easy to print as PLA.

You should print any ABS or ASA material only in well ventiluated rooms however, the fumes aren't too healthy. But then, you shouldn't inhale any printer fumes too much.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: MK4 upgrade printable parts PETG vs PLA

Ah, thanks for the tip. I had a look at the specs at 3djake. Very interesting. For higher durability I have only tried Nylon CF like eSun's PAHT CF. Printed the MK3S+ upgrade parts for the toolhead on my MK3S with that. No problem with warping, but tends to clog nozzles like there is no tomorrow. 🙂 Had to increase the initial nozzle temp a few times until the clogging stopped. I also want to try the PC Blend from Prusa in the next weeks.

RE:

I have mixed reports for Nylon, even with CF. There creep can be an issue too. The Voron community is recommending very strongl ABS, ABS+ or ASA for Vorons. But those printer are usually enclosed with chamber temperatures up to 60°C being quite possible.

For a Prusa in a more spacious enclosure I have never had a problem with my PETG printed printer. The only thing I have replaced was the original fan shroud which I printed in Prusamen PC-Blend. Very challenging to print and warps a lot but for such small parts like the shroud which has to stand up to quite some heat it worked very well. I would not recommend PC-Blend for any larger parts and parts not affected by heat.

I strongly recommend using Magigoo PC as adhesive for PC-Blend. I had otherwise troubles with plate adhesion, with and without Kores.

And print with skirt to the full height of your printed object in the centre of your build plate (make sure your skirt is printed on top of the brim of the object to prevent detachment of the skirt due to warping). Enclosure recommended.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: MK4 upgrade printable parts PETG vs PLA

PC-CF is the way to go... with a hardened/coated nozzle, of course. That stuff prints without and enclosure as easily as PLA but stands up to the heat and stress. Downside is no color selection but if you don't mind the nice charcoal grey, it's great for structural stuff where heat tolerance is also relevant.

I have mixed reports for Nylon, even with CF. There creep can be an issue too. The Voron community is recommending very strongl ABS, ABS+ or ASA for Vorons. But those printer are usually enclosed with chamber temperatures up to 60°C being quite possible.

For a Prusa in a more spacious enclosure I have never had a problem with my PETG printed printer. The only thing I have replaced was the original fan shroud which I printed in Prusamen PC-Blend. Very challenging to print and warps a lot but for such small parts like the shroud which has to stand up to quite some heat it worked very well. I would not recommend PC-Blend for any larger parts and parts not affected by heat.

I strongly recommend using Magigoo PC as adhesive for PC-Blend. I had otherwise troubles with plate adhesion, with and without Kores.

And print with skirt to the full height of your printed object in the centre of your build plate (make sure your skirt is printed on top of the brim of the object to prevent detachment of the skirt due to warping). Enclosure recommended.

RE:

PC, PC-CF, ASA, ABS, PETg, PA-CF ?. which one is better for printer parts ?. It depends on how big it is the model and how much heat or mechanical stress it will be enduring,

ASA/ABS is the best compromise for cost/performance and serves well for almost everything. Filaments like PC or CF-PA have better heat endurance and are harder but they can be too rigid sometimes and, therefore, more prone to cracking if mechanically stressed too much. ASA or ABS, having a certain amount of elasticity, support better strong torsion and flexion forces, which helps also to damp the resonances on fast moving parts,

No perfect material for everything but I wouldn’t use PLA for printer parts, not even things like LCD screen mounts. PETG is OK. except in close contact with the heater block or the hotbed, but there’s no reason to not use ABS/ASA instead, other than if you have trouble with warping when printing those filaments.

RE: MK4 upgrade printable parts PETG vs PLA

PLA is strong, but brittle. If you look at Prusa's material chart, you'll see impact resistance is quite low. PETG tends to flex a little, so it's less likely to flat out break (hence higher impact resistance). PLA also has very poor UV resistance, so it will degrade over time in direct sunlight.

RE: MK4 upgrade printable parts PETG vs PLA

ABS, ABS+ and ASA are not just good compromises of price and performance but they also do not share the potential issues which PC or PA-CF have. PC is more sensitive towards abrasion and lubricants with the risk of cracking. That is if you have no issues with warping to begin with (if you use PC-CF for example). PA-CF can have big issues with creeping, even with the CF. CND Kitchen had creeping issues with PA-CF in his V0 build.

So I wouldn't see ABS or ASA as best compromise but rather as the overall best choice for enclosed printers without active chamber heating. Before you reach temperatures which are problematic for the ABS in the enclosure you will run already into issues with your lubricant or your motors.

I did print my extruder vor my V0.1 in PC-Blend, which was rather discouraged on the voron Discord but it has performed so far well, no sign of cracks even though I will see printing non-tiny parts without any warping is not possible on a hobbyist machine, PC-CF might be able to do that though but I don't know if that is more or less prone to cracking than PC-Blend. What I do know is that PC feels more rigid but also transports vibrations better than ABS which seems to dampen them more.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: MK4 upgrade printable parts PETG vs PLA

Concurring with your opinions, I’d say that the mechanical properties of PC and PA filaments vary a lot depending on the specific brand and type. Some nylons may be too elastic, some PCs too rigid and prone to crack while others won’t have those problems.

As other people here, I have printed on PC blend a fan shroud for my MK3S. It performs flawlessly, although this isn’t a part that endures mechanical stress, only heat. Your Voron extruder on PC blend works fine too.

Later, I printed on Prusament PA11-CF the hotend mount of my Voron 2.4, looking for best heat resistance ( probably overkill, ASA might have been enough), Weeks later I switched from the older Afterburner toolhead to the newer Stealthburner, so I had to replace the mount with another one compatible with the Stealthburner. I’m checking right now the two parts of the old mount and, after 2 months of use, they’re totally unmarked, no warping, creep or shrinkage of any kind, looking as good as new.

I don’t know which PA-CF filament used the CNC guy but sure it wasn’t Prusament PA11-CF.

RE: MK4 upgrade printable parts PETG vs PLA

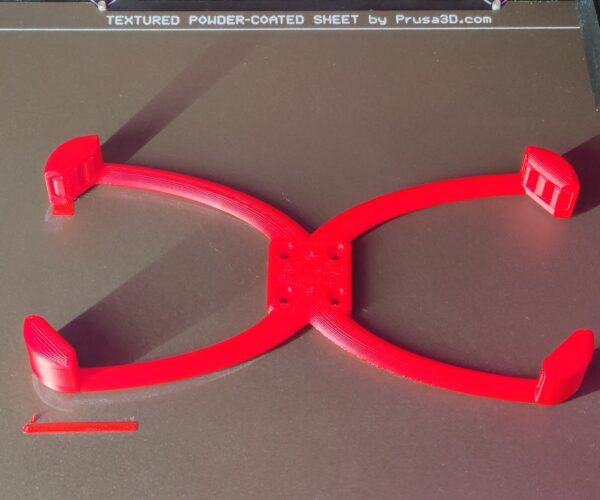

I just tested some red TitanX for a phone holder on my e-bike. No warping at all. I used the profile for eSun ABS as a starting point, then 265 °C nozzle and 100 °C on the bed, enclosure, gluestick on the textured sheet and the print came off the sheet after cooling just like PETG. The support material also came off very easily. Very nice material.

The first photo shows the part still on the sheet after cooling. The trace on the sheet is from a previous print. Red is not very AF-friendly in my LED lighting, sorry.

This is a detail of one of the corners before removing the supports inside the corner. That is the fluffy stuff on the right hand side.

This shows the whole part after removing the supports.

This shows the inside of the corner where the supports were.

Currently I am using a PETG print of this part on my e-bike. The bendiness of the arms that is required for attaching and detaching the phone feels about the same as on the PETG print. I'll change it out for this to test it in use and will keep the PETG print as a spare.

So to get back on topic, this could also be a viable material for printable parts on our printers. It is easier to print than regular ABS/ASA. I printed it in an enclosure, but on my previous ASA prints in the enclosure I still had a bit of warping that I had to counteract with mouse ears and draft shield. The choice of colors is a bit sparse and it is more expensive than regular ABS/ASA, but you do not need mouse ears and draft shields, and it keeps the cursing frequency very low! 😉

Or just stick with PETG, it works very well! 🙂

RE:

TitanX is indeed an incredibly nice matieral, good layer adhesion too. Feels like it shows even less warping than PETG. It is certainly some form of mix or heavily modified ABS as it is also more resistant to acetone than regular ABS. A disadvantage to PETG might be that it could be less resistent to UV light, ie preform worse over long term outside. But maybe it is better in that regard than regular ABS as well.

I also tested it for material creep over several weeks under stress. It performs quite similarily to regular ABS in that regard, ie fairly good and its thermal performance is similar too, that means also much better than PETG.

According to rumors 3djake NiceABS is the same material as TitanX and it tends to be a bit less expensive at least. Another option to save a bit of money is to go for the recycled TitanX, which is available for all colours as long as the colour you are looking for is black 😉

Purely subjectively but I think TitanX and ABS in generally has a much nicer surface finish than PETG, but more importantly it is a bit stiffer than PETG which is something you may or may not be looking for.

SUMMARY: Use TitanX if you need more thermostability and/or slightly stiffer material than PETG with zero warping. Don't use it for outdoor applications

Mk3s MMU2s, Voron 0.1, Voron 2.4