Love-board-cover-right prevents X-axis from going all the way right

Wondering if anyone else had this problem when assembling. When the love-board-cover-right is installed I noticed it doesn't let the X-axis reach all the way (there's a small gap between the carriage and the X-idler). When the cover is off it does go all the way. It seems to be hitting the M3 socket head on the trapezoid nut. I did follow the assembly instructions and made sure the cover was flat against the extruder motor. The gap is pretty small, maybe 3mm, but still noticeable so I have the cover off for now.

RE:

I am still waiting for my MK4, so I can not tell much about it, but possibly it will help to use a different screw (countersunk screw) ?

This at least should give a bit more space, although it will not be 3mm.

RE:

Thanks for the imput, i saw the build video from Steve Builds where he faced the exact same thing. I had created a post called the Good the Bad and the Ugly and i got trolled for this and we should all be posting on the manuals ONLY..which i disageree I wanted to see comments on build experince which I class your post as being. To keep everyone happy please make a post in the manual steps online stating this issue in the correct place and then wait to see if Prusa change the design of the cover or just remove this piece and make it optional

Part 1 -

Part 2 - (complete and first print)

RE: Love-board-cover-right prevents X-axis from going all the way right

I had the same problem. The cover touches the Z axis screw.

Using a file to remove a little material at the point solves the problem.

RE: Love-board-cover-right prevents X-axis from going all the way right

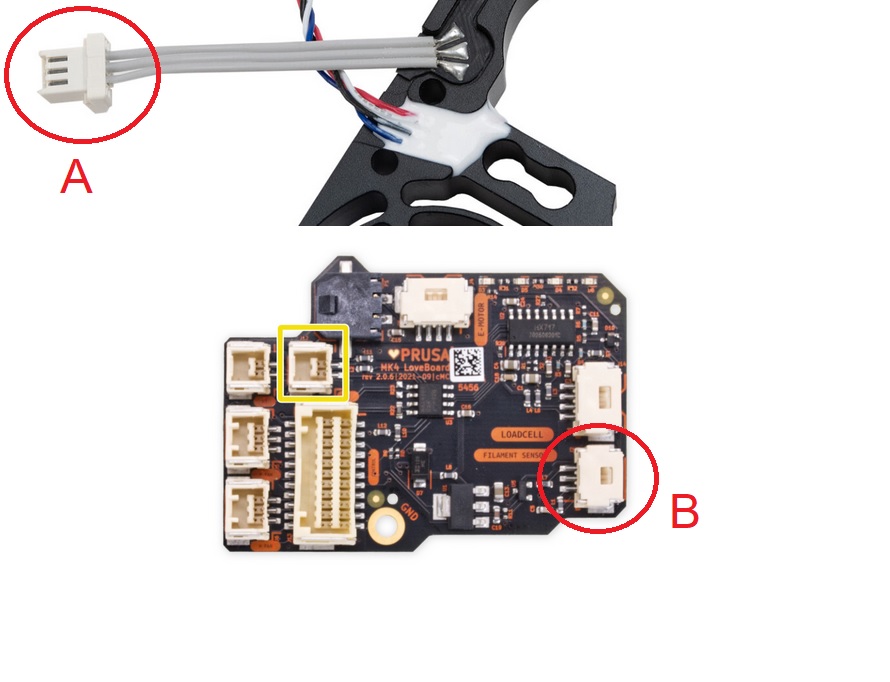

I had the exact same problem. I had to be extra cautious about the cable routing and tried to replicate exactly the wire routing shown for the Hall effect sensor cable and it worked after that.

RE: Love-board-cover-right prevents X-axis from going all the way right

That is a typical design flow. It requires a 180° twist if the cable instead of just a simple flat curved connection.

They would have carefully planned the contacts order on the A and B connector without the need to twist the cable. Now it is too late, and to have compatibility with the existing LoveBoards the only things is to manufacture a new HALL sensor revision board with inverted soldering order, and the connector would result rotated 180°. This will maintain the signal in the connector pins, but will not require the cable twist. In this way, the new and old sensor hall boards can be used together with the existing LoveBoard.

RE: Love-board-cover-right prevents X-axis from going all the way right

Another easy solution could be to desolder the wires 1 & 3 on the Sensor hall, rotate 180° the connector and resolder the wires 1 & 3 accordingly in a way that you have just twisted the connector and not the contacts. In this way you will have just to connect the connector to the LoveBoard without any twist.

I will see what to do on my kit once it will arrive.

RE: Love-board-cover-right prevents X-axis from going all the way right

Same here. I contacted support regarding the issue and their suggestion was:

1. Remove cover and finish X axis calibration. Then install it back. That what I did.

or

2. To reprint the cover and cut of ~0.4 (or less) from the top to increase clearance.

RE:

I'm going to throw this out and see where it lands.. Can you not "shave" a little off around the part, it's only a few mm isn't it? I for one don't want to start removing solder and then re-soldering.

RE: Love-board-cover-right prevents X-axis from going all the way right

Probably, as official solution Prusa will release just a very thin new cover with more space for the wires. 😉

RE: Love-board-cover-right prevents X-axis from going all the way right

In my case, it doesn't matter if the loveboard-cover-right is flush against the extruder or not, because it already is but still hits the trapezoid nut screw, so I don't think rearranging the cables will help. Shaving would probably help, but taking it off completely is easier for now. I guess I'll wait for a redesign.

RE: Love-board-cover-right prevents X-axis from going all the way right

As already written above, simply grind off some material where the cover meets the screw. Writing that takes longer than grinding. Don't make it so complicated.

RE: Love-board-cover-right prevents X-axis from going all the way right

another option and i think it is mentioned already, to remove the cover, conduct the start up test and let it pass and then "shave" the part a little and replace the cover or just wait and pray Prusa come up with a new part design.....oh wait Prusa don't read this forum.

RE: Love-board-cover-right prevents X-axis from going all the way right

I had this and another issue with X calibration. One of the zip ties on the cable mount wasn't trimmed short enough and was hitting the PSU. After cutting that back I still had X failures. I removed the side cover and X passes without a problem. My side cover was tight and the cables were inside it reasonably well. The top fit correctly with the side. I think this is just a design issue where only one screw in the back allows the front to deflect out under pressure from the cables. I understand the need to try to maximize the machine volume while minimizing the footprint but this just seems like a tolerance flaw. There is no reason so many things need to be so close to the end stop width.

RE: Love-board-cover-right prevents X-axis from going all the way right

I had no issues with this, and everything clears with no interference. All axis movements are as expected, my issue is with PETG first layer adhesion on the textured plate. See my post elsewhere.

RE: Love-board-cover-right prevents X-axis from going all the way right

Could you take a picture of your extruder with it pushed all the way to the right? Here's mine showing the flat cover, but a gap in between the X-idler and carriage.

I had no issues with this, and everything clears with no interference. All axis movements are as expected, my issue is with PETG first layer adhesion on the textured plate. See my post elsewhere.

RE: Love-board-cover-right prevents X-axis from going all the way right

Even after a few prints I had problems with the adhesion on the satin sheet. And as always, the cleaning helps me with a kitchen sponge and dish soap. Then with ipa. Just ipa is sometimes not enough.